113335 - 12

www.amdry.com

11

Exhaust Transition Piece

(Gas and Electric Only!)

Inside the tumbler of this dryer is an exhaust transition piece

that must be installed on the outlet of the exhaust before any

further venting is connected:

Remove the exhaust transition piece from the tumbler and

place it on the exhaust outlet.

Using the screws provided, secure the exhaust transition

piece to the dryer.

NOTE: It is recommended that this joint be taped as well

as all other duct joints to prevent moisture and lint from

escaping into the building.

WARNING

An exhaust duct transition piece is shipped inside of the

dryer’s tumbler and

MUST

be installed on the dryer’s

exhaust duct, with the hardware provided,

BEFORE

location venting is connected to the dryer.

THIS EXHAUST DUCT TRANSITION PIECE

MUST BE INSTALLED FIRST!

Failure to observe this installation requirement may result

in damage to the dryer, create a

FIRE HAZARD

and will

VOID

the manufacturer’s warranty.

012999JEV-GS/cj

P/N: 114092

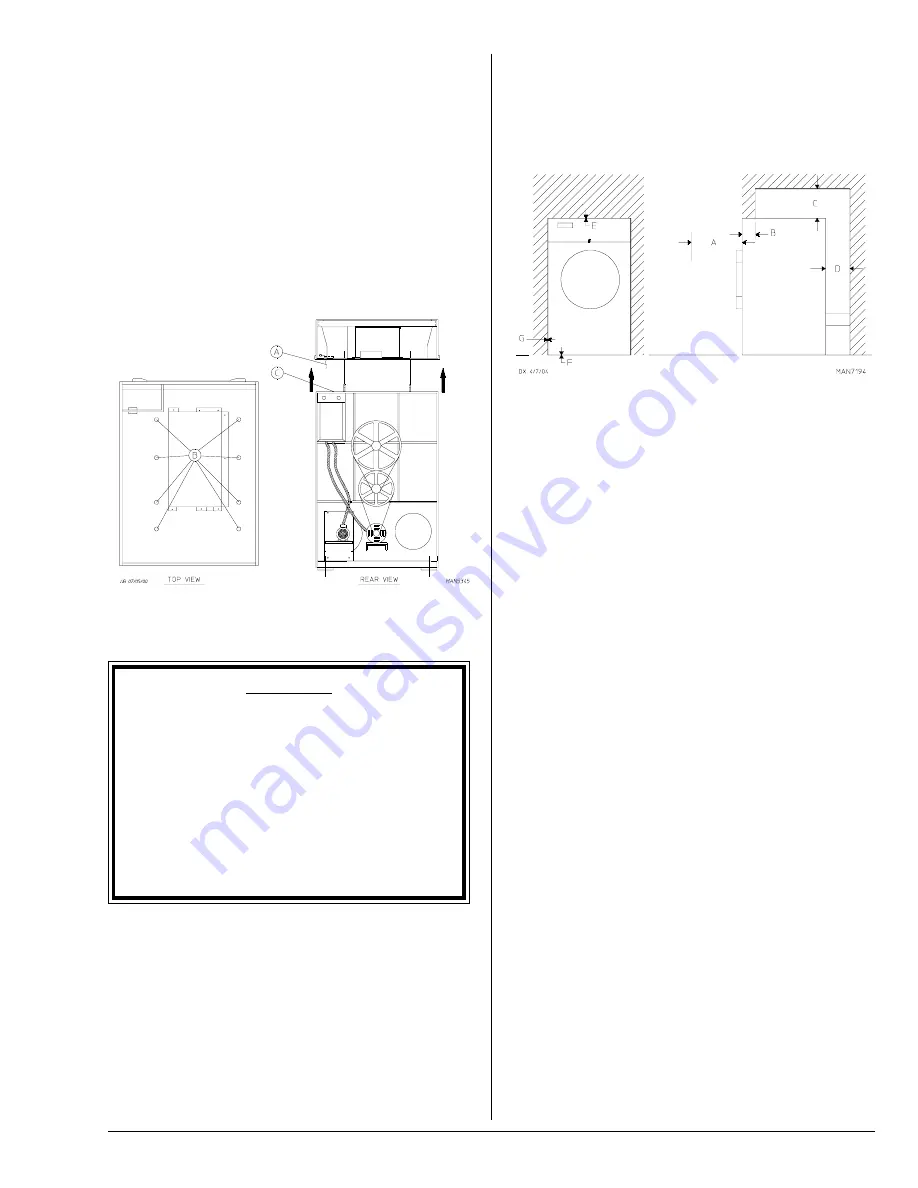

A

40-inches (101.6 cm) for optimum opening of load door.

B

The maximum thickness of the bulkhead is 4-inches (10.16 cm). For electric

dryers the maximum thickness of the bulkhead is 1-inch (2.54 cm) within

3-inches (7.62 cm) from the top of the control door.

C For gas and electric dryers a minimum overhead clearance of 12-inches

(30.48 cm) is required, providing no sprinkler is located above the dryer.

For steam dryers or if a sprinkler is located above the dryer, 18-inches

(45.72 cm) is required.

D Dryer should be positioned 24-inches (60.96 cm) away from the nearest

obstruction and 36-inches (91.44 cm) is recommended for ease of

installation, maintenance, and service.

E

2-inch (5.08 cm) minimum is required for opening the control door.

F

Flooring should be level or below dryer cabinet for ease of removing panels

during maintenance.

G Dryers may be positioned sidewall to sidewall, however a 1/16” (1.5875

mm) minimum allowance must be made for the opening and closing of the

control door, along with the removal of panels during maintenance.

Even though a 12-inch (30.48 cm) clearance is acceptable,

it is recommended that the rear of the dryer be positioned

approximately 2 feet (0.61 meters) from the nearest

obstruction (i.e., wall) for ease of installation, maintenance,

and service. Bulkheads and partitions should be made from

noncombustible materials. The clearance between the

bulkhead header and the dryer must be a minimum of

4-inches (10.16 cm) and must not extend more than 4-inches

(10.16 cm) to the rear of the front. The bulkhead facing must

not be closed in all the way to the top of the dryer. A 2-inch

(5.08 cm) clearance is required.

NOTE: Bulkhead facing should not be installed until after

the dryer is in place. Ceiling area must be located a

minimum of 12-inches (30.48 cm) above the top of the

dryer.

IMPORTANT: Even though a minimum of only 12-inches

(30.48 cm) is required, 18-inches (45.72 cm) or more is

suggested, for steam dryers and especially in cases where

sprinkler heads are over the dryers.

NOTE: When fire sprinkler systems are located above the

dryers, a minimum of 18-inches (45.72 cm) above the

dryer console (module) is suggested. Dryers may be

positioned side wall to side wall, however, 1- or 2-inches

(2.54 or 5.08 cm) is suggested for ease of installation and

maintenance. Allowances must be made for the opening

and closing of the control door and the lint door.

Dryer Enclosure Requirements _______

Bulkheads and partitions should be made of noncombustible

material.

NOTE: Allowances must be made for opening the control

door.

To Remove Top Console (Module)

Disconnect the ground wire (A) at the rear upper left hand

corner of dryer.

Remove the 8 sets of nuts and washers (B) holding the

console (module) to base.

Open the control door/control panel and disconnect the white

15-pin plug connector (C) (illustration below) located in the

base of the control box.

Disconnect white plug connector located outside backside

of the control box (provides power to heat circuit).

Lift the console (module) off the dryer base.

IMPORTANT: The dryer must be transported and handled

in an upright position at all times.

Содержание ML-130 III

Страница 28: ...ADC Part No 113335 12 07 31 08 5 ...