4

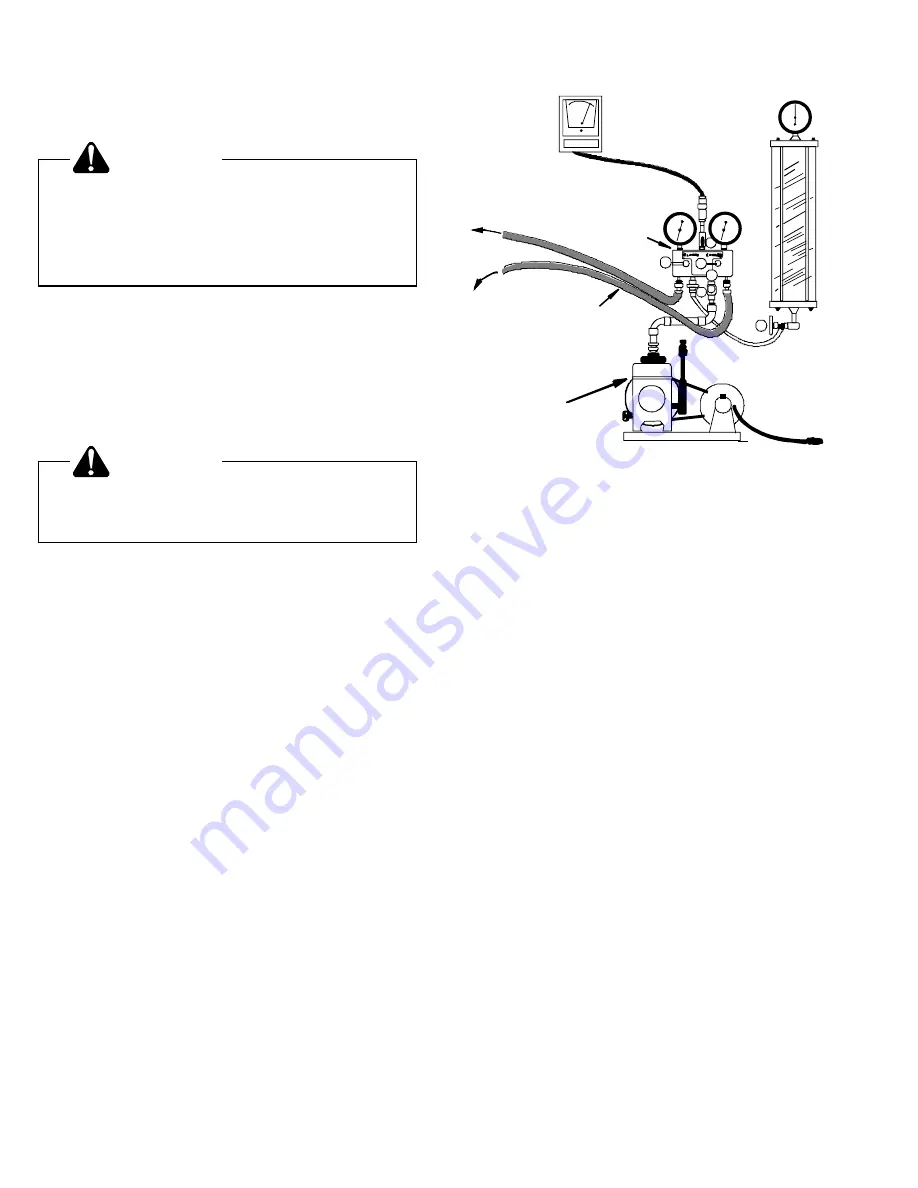

A. HIGH SIDE VALVE

B. LOW SIDE VALVE

C. VACUUM PUMP

D. THERMOCOUPLE GAUGE

E. MANIFOLD GAUGE

F. CHARGING CYLINDER

C

A

B

E

D

HIGH VACUUM PUMP

LARGE DIAMETER

BRAIDED VACUUM

HOSES

TO

RELATED

GAUGE

PORTS OF

COND. UNIT

HIGH VACUUM

MANIFOLD

LOW SIDE

GAUGE

HIGH SIDE

GAUGE

DIAL-A-CHARGE

CHARGING CYLINDER

THERMOCOUPLE

VACUUM

GAUGE

F

Figure 2

5. Open the high and low side valves on the gauge

manifold. Keep the valve on the charging cylinder itself

closed, but open the valve on the gauge manifold that

leads to the cylinder.

6. Evacuate the system to about 29 inches of vacuum as

measured by the compound (low side) gauge.

7. Open the valve to the thermocouple vacuum gauge.

Evacuate until the gauge reads 250 microns or less.

8. Close the valve to the vacuum pump. Wait five min-

utes, then check the pressure on the thermocouple

vacuum gauge:

a. If the pressure is not more than 1500 microns, the

system is leak-free and properly evacuated. Pro-

ceed to Step 9.

b. If the pressure rises, but holds at about 5000

microns, moisture and noncondensibles are still

present. Open the valve to the vacuum pump, and

go back to Step 7.

c. If the pressure rises above 5000 microns, a leak is

present. Go back to “Leak Testing” section on page

4.

9. Close the valve to the thermocouple vacuum gauge.

Close the valve to the vacuum pump. Shut off the

pump.

way.) Attach this gauge manifold to the service valves

on the unit. Do not open the unit service valves. Do not

use refrigerant from the unit for leak testing - it has

been precisely measured at the factory for optimum

performance.

WARNING

To avoid possible explosion, the line from

the nitrogen cylinder must include a

pressure regulator and a pressure relief

valve. The pressure relief valve must be set

to open at 175 psig or less.

2. Connect a cylinder of dry nitrogen to the center port on

the gauge manifold.

3. Open the hand valve a minimal amount on the line

coming from the nitrogen cylinder.

4. Open the high pressure valve on the gauge manifold.

Pressurize the refrigerant lines and the indoor coil to

150 psig (1034 kPA). To reach 150 psig, you may need

to further open the hand valve on the nitrogen cylinder.

WARNING

To avoid possible explosion or equipment

damage, do not exceed 150 psig when

pressure testing.

After you reach 150 psig, close the valve on the nitrogen

cylinder. Disconnect it from the gauge manifold. If you plan

to use an electronic leak detector, add a trace of R-22 to

the system (if permitted by current EPA regulations).

5. Put a soap solution on all connections and joints. If you

see bubbles, you have a leak. Mark these locations.

6. Use the gauge manifold to carefully release the nitro-

gen from the system. If leaks were found, repair them.

After repair, repeat the above pressure test. If no leaks

exist, proceed to system evacuation.

ID COIL AND LINE SETS EVACUATION

1. To speed nitrogen release, use a core puller to remove

the valve cores from the service valves.

2. Connect the vacuum pump, high vacuum manifold set

with high vacuum hoses, thermocouple vacuum gauge

and charging cylinder as shown. Begin with all valves

fully closed.

3. Your first step will be only to confirm proper pump and

gauge operation. Open only the shutoff valve which

leads to the vacuum pump (Figure 2)(C). Start the

pump. After the gauge manifold (low side) reading

drops to about 29 inches of vacuum, open only the

valve to the thermocouple vacuum gauge(D). Evacu-

ate until the gauge reads 250 microns or less.

4. Close the valve to the thermocouple vacuum gauge(D).

This will avoid potential gauge damage from “pegging

the meter”. Now that proper pump and gauge opera-

tion has been confirmed, you are ready to begin the

actual evacuation of the lines and indoor coil.