12

Suggested Field Testing/Trouble Shooting

1. Run unit in the heating mode (room thermostat calling for heat).

2. Check unit for proper charge.

NOTE: Bands of frost on the condenser coil indicate low refrigerant charge.

3. Shut off power to unit.

4. Disconnect outdoor fan by removing the outdoor fan motor wire from “DF2” on defrost control.

5. Restart unit and allow frost to accumulate.

6. After a few minutes of operation, the unit’s defrost thermostat should close. To verify this, check for 24 volts between “DFT” and

“C” on board. If the temperature at the thermostat is less than 28°F and the thermostat is open, replace the unit’s defrost

thermostat, as it is defective.

7. When the unit’s defrost thermostat has closed, short the test pins on the defrost board until the reversing valve shifts, indicating

defrost. This should take up to 22 seconds depending on what timing period the control is set on. After defrost initiation, the

short must instantly be removed or the unit’s defrost period will only last 3 seconds.

8. The control is shipped from the factory with the compressor delay option selected. This will de-energize the compressor

contactor for 30 seconds on defrost initiation and defrost termination. If the jumper is set to Normal, the compressor will

continue to run during defrost initiation and defrost termination. The control will also ignore the low pressure switch connected

to R-PS1 and PS2 for 5 minutes upon defrost initiation and 5 minutes after defrost termination.

9. After the unit’s defrost thermostat has terminated, check the defrost thermostat for 24 volts between “DFT” and “C”. The reading

should indicate 0 volts (open sensor).

10. Shut off power to unit.

11. Replace outdoor fan motor lead to terminal “DF2” on defrost board and turn on power.

A

IR

FLOW

M

EASUREMENT

AND

A

DJUSTMENT

Please review the

Duct Work

section before proceeding with the airflow measurements and adjustments in this section.

Unit blower curves (see Specification Sheets) are based on external static pressure (ESP per in/W.C.). The duct openings on the

unit are considered internal static pressure. As long as ESP is maintained, the unit will deliver the proper air up to the maximum

static pressure listed for the CFM required by the application (i.e. home, building, etc.)

In general, 400 CFM per ton of cooling capacity is a rule of thumb. Some applications depending on the sensible and latent

capacity requirements may need only 350 CFM or up to 425 CFM per ton. Check condition space load requirements (from load

calculations) and equipment expanded ratings data to match CFM and capacity.

After unit is set and duct work completed, verify the ESP with a 1-inch inclined manometer with pilot tubes or a Magnahelic gauge

and confirm CFM to blower curves in the Specification Sheets.

NOTE:

Never run CFM below 350 CFM per ton, evaporator freezing or poor unit performance is possible.

A

IR

F

LOW

A

DJUSTMENTS

F

OR

I

NDOOR

B

LOWER

M

OTOR

ECM Motor

The ECM control board is factory set with the dip switch #4 in the “ON” position for single stage units and to the "OFF" position for

the 2 stage units. All other dip switches are factory set in the “OFF” position.

For most applications, the settings are to be changed

according to the electric heat size.

The ECM motor provides many features not available on the traditional PSC motor. These features include:

•

Improved Efficiency

•

Constant CFM

•

Soft Start and Stop

•

Improved Humidity Control

ECM Motor Speed Adjustment

Each ECM blower motor has been preprogrammed for operation at 4 distinct air flow levels when operating in Cooling/Heat Pump

mode or Electric Heat mode. These 4 distinct levels may also be adjusted slightly lower or higher if desired. The adjustment

between levels and the trim adjustments are made by changing the dip switch(s) either to an "OFF" or "ON" position.

See Appendix for Blower Performance Data tables.

APH D

IP

S

WITCH

F

UNCTIONS

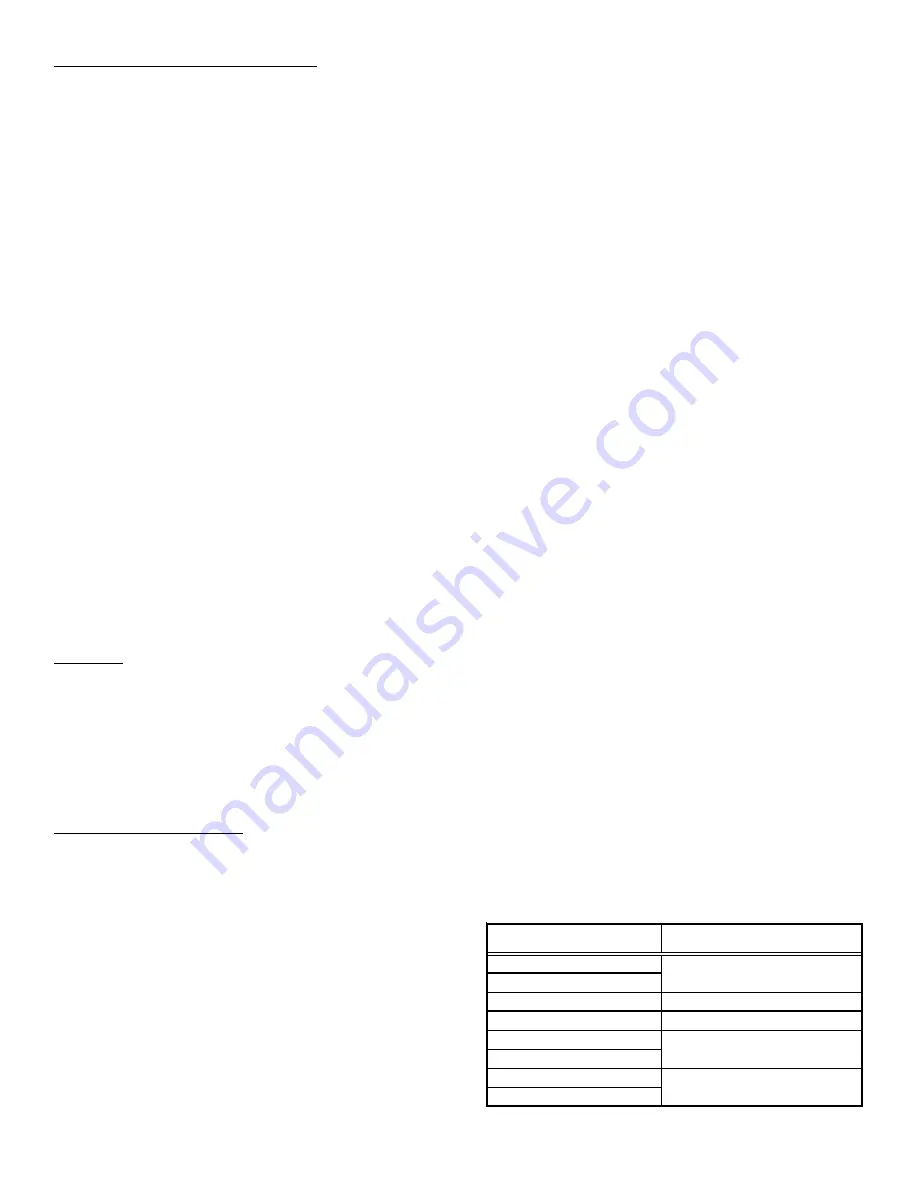

The ECM motor has an electronic control that contains eight (8) 2-

position dip switches. The function of these dip switches is shown

in

Table 1.

APH CFM D

ELIVERY

AND

A

DJUSTMENTS

See Appendix for CFM Output, Adjustments and DIP switch

settings.

APH T

HERMOSTAT

“F

AN

O

NLY

” M

ODE

During Fan Only Operations, the CFM output is 50% of the high stage

cooling setting.

DIP SWITCH NUMBER

FUNCTION

1

2

3

N/A

4

Indoor Thermostat

5

6

7

8

Cooling & Heat Pump CFM

CFM Trim Adjust

Elect ric Heat

Table 1

Содержание APG1624060M41

Страница 16: ...16 APPENDIX...

Страница 23: ...23 THIS PAGE LEFT INTENTIONALLYBLANK...