6.

PLACEMENT OF FOOD PROBE (OPTIONAL)

If the unit is equipped with the probe accessory, wipe each

probe and probe tip with a disposable alcohol pad to clean

and sanitize before using. If the probe is left in its bracket,

the LED temperature display will indicate the ambient air

temperature inside the case. To place a probe into food

kept in the case, remove the probe from the bracket and

push the probe tip halfway into the product, positioning the

tip at the center of the food mass. If placing into solid

foods such as meat roast or poultry breasts, push the

probe in from a straight downward position or in from the

side to the center position. If placing into a semi-liquid or

liquid product, the probe cable will probably need to be

secured to keep the probe positioned properly. Do not let

the probe tip touch the edges or side of the container.

Tape the probe cable to the lip or edge of the container.

Wipe each probe tip with a clean paper towel to remove

food debris after each use. Follow by wiping probes with a

disposable alcohol pad. Return each probe to the proper

bracket position.

7.

SERVE FRESH HOT DELI FOOD

Keep hot deli foods looking fresh. Occasionally stir or rotate

foods as needed. Serve products in the proper package or

container. Keep display case doors closed after serving.

Wipe spills immediately to assure maximum eye appeal.

The cleanliness and appearance of this unit will contribute

considerably to operating efficiency and

savory, appetizing food. Good equipment

that is kept clean works better and

lasts longer.

1.

CLEAN THE PROBES DAILY

Remove all food soil from probes.

Wipe entire probe and cable assembly with warm

detergent solution and a clean cloth. Remove detergent

by wiping each probe and cable with clean rinse water and

a cloth. Wipe probes with disposable alcohol pad or

sanitizing solution recommended for food contact

surfaces. Allow probe and cable to air dry in probe

holding bracket.

2.

THOROUGHLY CLEAN THE DISPLAY CASE DAILY

A. Turn lights and adjustable thermostat(s) to the “

OFF

”

position, and disconnect unit from power source.

B. Remove, cover or wrap, and store unused products

under refrigeration.

C. Clean the interior metal surfaces of the cabinet with

a damp cloth and any good alkaline or alkaline

chlorinated based commercial detergent or grease

solvent at the recommended strength.

Use a plastic scouring pad or oven

cleaner for difficult areas. Avoid the use

of abrasive cleaning compounds, chloride

based cleaners, or cleaners containing

quaternary salts. Rinse well to remove

all residue and wipe dry.

NOTE:

Never use hydrochloric acid (muriatic acid) on

stainless steel.

D. Clean the glass with a window cleaner.

E. To help maintain the protective film coating on polished

stainless steel, clean the exterior of the unit with a cleaner

P g . 2

®

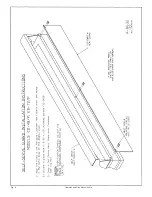

ED-48/P

120/208-240 V.A.C. — 60 Hz, 1 ph

At 208V:

2800 Watts, 16.6 Amps

NEMA L14-30P

At 240V:

3400 Watts, 18.0 Amps

30A, 250V Plug

— Plug provided for counter-top applications only.

SYSTEM APPLICATIONS

BARE END — NO PLUG

220 V.A.C. — 50 Hz, 1 ph

3000 Watts, 13.6 Amps

BARE END — NO PLUG

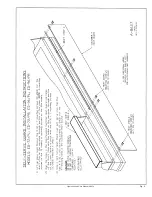

ED-72/P; ED-72/PL; ED-72/PR

120/208-240 V.A.C. — 60 Hz, 1 ph

At 208V:

5140 Watts, 22.5 Amps

NEMA L14-30P

At 240V:

5140 Watts, 22.5 Amps

30A, 250V Plug

— Plug provided for counter-top applications only.

SYSTEM APPLICATIONS

BARE END — NO PLUG

220 V.A.C. — 50 Hz, 1 ph

4650 Watts, 21.1 Amps

BARE END — NO PLUG

ED-96/PL; ED-96/PR

120/208-240 V.A.C. — 60 Hz, 1 ph

At 208V:

5100 Watts, 22.5 Amps

NEMA L14-30P

At 240V:

6000 Watts, 24.7 Amps

30A, 250V Plug

— Plug provided for counter-top applications only.

SYSTEM APPLICATIONS

BARE END — NO PLUG

220 V.A.C. — 50 Hz, 1 ph

5400 Watts, 24.5 Amps

BARE END — NO PLUG

Operation and Care Manual #881-3

C A R E a n d C L E A N I N G

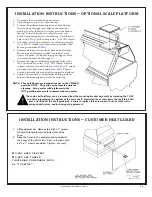

H o o d g l a s s ex t e n d e d t o t h e f u l l u p r i g h t

p o s i t i o n i s s t a b i l i z e d t h r o u g h t h e u s e

o f g a s s t r u t s d e s i g n e d f o r t h e f u l l

l o a d b e a r i n g w e i g h t .

T h e s e s t r u t s

c o u l d w e a k e n o r f a i l d u e t o w e a r,

e nv i r o n m e n t a l c o n d i t i o n s o r a g i n g .

Operators should be aware of any decrease in effort to lift

the hood and initiate an immediate gas strut safety check.

D O N OT L I F T T H E H O O D I N T H I S C O N D I T I O N .

!

C A U T I O N

A t n o t i m e s h o u l d t h e c a s e b e

s t e a m c l e a n e d , f l o o d e d w i t h

w a t e r o r l i q u i d s o l u t i o n .

D o n o t u s e w a t e r j e t t o c l e a n .

S e v e r e d a m a g e o r e l e c t r i c a l

h a z a r d c o u l d r e s u l t .

D i s c o n n e c t f r o m p o w e r s o u r c e b e f o r e

c l e a n i n g o r s e r v i c i n g .

Always follow appropriate state or local

health (hygiene) regulations regarding all applicable

cleaning and sanitation requirements for

equipment.recommended for stainless steel surfaces.

Spray the cleaning agent on the cloth and wipe with the

grain of the stainless steel.

Содержание ED-48/P

Страница 5: ...Operation and Care Manual 881 3 Pg 4 ...

Страница 6: ...Pg 5 Operation and Care Manual 881 3 ...

Страница 11: ...Operation and Care Manual 881 3 Pg 10 ...

Страница 12: ...Operation and Care Manual 881 3 Pg 11 ...

Страница 14: ...Operation and Care Manual 881 3 Pg 13 ...

Страница 16: ...Operation and Care Manual 881 3 Pg 15 ...

Страница 18: ...Operation and Care Manual 881 3 Pg 17 ...

Страница 19: ...Operation and Care Manual 881 3 Pg 18 ...

Страница 21: ...Operation and Care Manual 881 3 Pg 20 ...

Страница 23: ...Operation and Care Manual 881 3 Pg 22 ...

Страница 24: ...Operation and Care Manual 881 3 Pg 23 ...

Страница 25: ...Operation and Care Manual 881 3 Pg 24 ...

Страница 26: ...Operation and Care Manual 881 3 Pg 25 ...

Страница 27: ...Operation and Care Manual 881 3 Pg 26 ...

Страница 28: ...Operation and Care Manual 881 3 Pg 27 ...

Страница 29: ...Operation and Care Manual 881 3 Pg 28 ...

Страница 30: ...Operation and Care Manual 881 3 Pg 29 ...

Страница 31: ...Operation and Care Manual 881 3 Pg 30 ...

Страница 32: ...Operation and Care Manual 881 3 Pg 31 ...