507335-02

Page 33 of 39

Issue 2001

In the event the unit loses ignition, the control will attempt

to recycle up to five times before it goes into a 1 hour

lockout. Lockout may be manually reset by removing

power from the control for more than 1 second or removing

the thermostat call for heat for more than 3 seconds.

If during a heating cycle the limit control senses an

abnormally high temperature and opens, the control board

de-energizes the gas valve and the combustion blower

while the circulating blower ramps up to 2nd stage heat

speed. The circulating blower remains energized until the

limits are closed.

Fan On

When the thermostat is set for continuous fan operation

and there is no demand for heating or cooling, a call for fan

closes the R to G circuit and the circulating blower motor

runs at 50% of the selected cooling CFM until switched off.

When the call for fan is turned off, the control de-energizes

the circulating blower.

Cooling

The unit is set up at the factory for single stage cooling. For

two stage cooling operation, clip the jumper wire located

between the Y to Y2 terminals on the integrated ignition/

blower control board.

If the active dehumidification feature is enabled, the

circulating blower runs at 82% of the selected cooling

speed as long as there is a call for dehumidification.

The system must not be in either the passive or active

dehumidification mode when charging a cooling system.

IMPORTANT

Single Stage Cooling

A call for cooling from the thermostat closes the R to Y

circuit on the integrated ignition/blower control board. The

control waits for a 1-second delay before energizing the

circulating blower to 82% of the selected cooling CFM

(passive dehumidification mode). After 7.5 minutes, the

circulating blower automatically ramps up to 100% of

the selected cooling airflow. When the call for cooling is

satisfied, the circulating blower ramps back down to 82%

of the selected cooling airflow for 1 minute, then shuts off.

Two Stage Cooling

A call for 1st stage cooling from the thermostat closes the

R to Y circuit on the control board. The control waits for a

1-second delay before energizing the circulating blower.

The blower motor runs at 57% of the selected air flow

for the first 7.5 minutes of the 1st stage cooling demand

(passive dehumidification mode). After 7.5 minutes, the

blower motor runs at 70% of the selected cooling air flow

until 1st stage cooling demand is satisfied.

A call for 2nd stage cooling from the thermostat closes

the R to Y2 circuit on the control board. The blower motor

ramps up to 100% of the selected cooling air flow. When

the demand for cooling is met, the blower ramps down to

Y1 until satisfied, then ramps down to 57% for 1 minute,

then turns off.

Heat Pump

For heat pump operation, clip the jumper wire located

below the O terminal on the integrated ignition/blower

control board. In heat pump mode, a call for heat will

result in the circulating air blower operating at the selected

cooling airflow after a brief ramp-up period.

Emergency Replacement Motor Operation

If the variable speed motor needs to be replaced in an

emergency situation (such as “no heat”) and an exact

replacement motor is not immediately available, a standard

PSC motor of equivalent frame size, voltage, rotation, and

horsepower can be temporarily installed until the correct

replacement motor can be obtained.

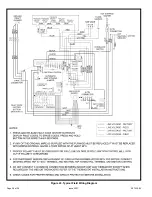

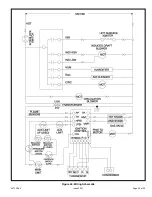

Connect the desired speed tap to the “EAC” terminal and

the neutral tap to the neutral terminal on the ignition control

(refer to the furnace wiring diagram). The ignition control

will control the motor’s operation, including a nominal 20

second “on” delay with a call for heat and a nominal 180

second “off” delay when the thermostat is satisfied. It will

also operate the motor on a call for cooling, with no “on” or

“off” delays.

Verify that the unit is operating at the desired speed and

within the rise range as shown on the unit rating plate.

The correct replacement motor must be installed as soon

as possible to ensure continued satisfactory operation of

the furnace.