507867-02

Page 52 of 54

Issue 2128

Cleaning the Burner Assembly

1. Turn off gas and electrical power to the furnace.

Remove heating compartment access panel.

2. Disconnect the gas supply line from the gas valve.

3. Disconnect and label wires from gas valve.

4. Disconnect ignitor wiring at 2 circuit plug.

5. Disconnect and label wires from rollout switch.

6. Disconnect and label flame sensor wire.

7. Disconnect and label ground wire from burner/manifold

assembly.

8. Remove four screws that secures burner/manifold

assembly to vestibule. Remove the assembly and

make note not to allow ignitor plate to dislodge from

the assembly.

9. Gently clean the face of the burners using the soft

brush attachment on a vacuum cleaner. Visually

inspect the inside of the burners and crossovers for

any blockage caused by foreign matter. Remove any

blockage and inspect for damage. Replace if damage

by rust or foreign matter cannot be removed.

10. Reinstall the burner/manifold assembly using the

existing four screws. Burners are self aligning to

center of clam shells.

11. Reconnect ground wire.

12. Reconnect flame sensor wire.

13. Reconnect rollout switch wires.

14. Reconnect ignitor wires.

15. Reconnect gas valve wires.

16. Reconnect gas supply line to gas valve.

17. Refer to instructions on verifying gas and electrical

connections when re-establishing supplies.

18. Follow instructions to place furnace in operation. Run

furnace 5 minutes to ensure burners are clean and

operating correctly.

19. Replace heating compartment access panel.

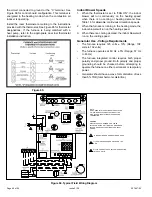

Table 17. Control Diagnostic Codes

Integrated Control LED Codes

Red LED Flash Code

2

Diagnostic Codes / Status of Furnace

LED Off

No power to control or control hardware fault detected

Heartbeat

1

Normal operation - idle, continuous fan, cool

Continuous Rapid Flash Call for heat / burner operation

1 Flash

Reverse line voltage polarity

2 Flashes

Improper earth ground

3 Flashes

Burner failed to light, or lost flame during heat demand

4 Flashes

Low flame signal - check flame sensor

5 Flashes

Watchguard - burner failed to light, exceeded maximum number of retries or recycles

6 Flashes

Control detected igniter circuit failure. Not available on all controls.

7 Flashes

Primary or Secondary limit open or watchguard mode - limit switch open longer than 3 minutes

8 Flashes

Rollout switch open

9 Flashes

Pressure switch failed to close or opened during heat demand

10 Flashes

Watchguard - Pressure switch opened 5 times during one heat demand

11 Flashes

Pressure switch stuck closed prior to activation of combustion air inducer

12 Flashes

Flame sensed without gas valve energized

13 Flashes

Low line voltage

1

A “heartbeat” is indicated by a “slow flash” - 1 sec on 1 sec off, repeating

2

Error codes are indicated by a “rapid flash” - the LED flashes X times at 1/2 sec on, 1/2 sec off, remains off for 3 sec, then repeats

NOTE

: Last 10 error codes are stored in memory, including when power is shut off to the unit. To recall, press and release button.

Most recent will be displayed first, LED off for 3 sec, then next error code is displayed, etc. To clear error codes, depress and hold

button longer than 5 seconds.