14

•

During the drilling process the cutter should be cooled permanently. Optimal cooling is possible by

internal cooling with the coolant unit.

•

Do not stop the motor during the drilling process. After the process draw the cutter back with running

motor.

Remove chips with chip-remover. Do not touch with bare hands. Danger of injury!

How to work with TCT core cutter type AL

•

Mount TCT core cutter with keyway on tool holder AL, MT3 and tighten set screw firmly.

How to work with twist drills

•

The drill chuck with MT 3 shank is only to be used with twist drills.

•

Insert drill chuck with adaptor in the arbor.

•

Insert twist drill in drill chuck and tighten drill chuck key.

•

Twist drills with MT 3 shank can be inserted directly into the arbor.

Tapping

The tapping attachment automatically switches over to left-hand rotation as soon as the spindle is turned back.

The motor can be continuously adjusted on the slide by releasing the Allan screw

(for a maximum enlargement of the stroke when using twist drills, drill chucks and

tapping attachments).

Cleaning and care

Pull plug prior to cleaning to avoid injuries by unintentional switching on.

•

Clean the outside of the motor with dry compressed air.

•

Check connecting lines on damages.

•

Clean and grease sliding surfaces regularly. Should lateral play arise by wear of the dovetail guide this

can be adjusted by adjusting the laterally positioned set screws (K).

•

Carbon brushes should be replaced after appr. 250 hours running time.

•

After the work is finished we recommend to store the Metal Core Drilling Machine in the transport case in

a lying position.

Содержание Rotabest 100

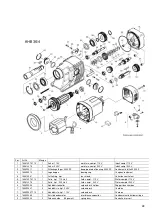

Страница 26: ...26 Ersatzteile Spare Parts Pi ces de rechange...

Страница 30: ...30...

Страница 31: ...31...