15

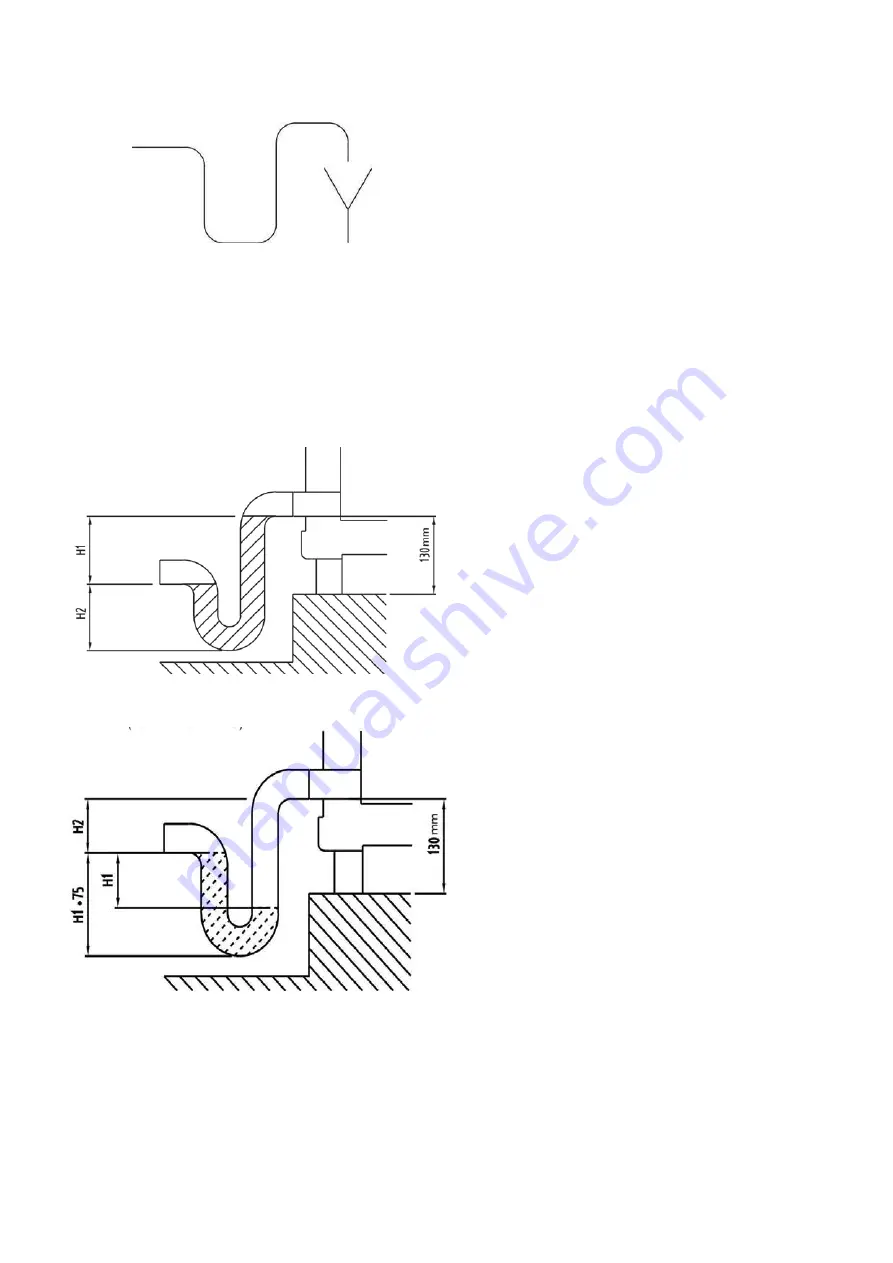

Positive pressure:

H1 = >maximum positive pressure in the cooler section (in mm WG) + 50 mm

H2 = 50 mm

Pressure in kPa (100 Pa = 10 mm WG)

•

Check if the droplet eliminator after the cooler has

been correctly installed.

•

Check if fins have been bent during transport.

•

Correctly straighten the fins.

•

The fins will only work correctly after several days in

dehumidification mode.

•

Start-up the cooling coil by opening the shut-off

valves. After several days of cooling operation check

the condensate drain and operation of the plastic

siphon.

•

If necessary clean the siphon.

•

City water can be used for water coils without any

conditioning.

4.7 - Heat recovery wheel

•

Ensure that the heat exchanger face area is not

damaged.

• Check that the wheel is rotating in the correct

direction.This is indicated by an arrow on the casing.

• Check if the wheel seals are fitting correctly.

• Check if belt tension is correct.

• Check if the motor and the rotation monitor have been

correctly connected (5 mm play between sensor and

detection point on the wheel).

• Ensure that the rotor speed has been correctly set.

The 39SQ condensation rotor must have a maximum

speed of 10 min-1; a sorption rotor must have a

maximum speed of 20 min-1. Refer to the user manual

for the heat recovery wheel controller.

• If the air intake temperature is below -15 °C, a pre-

heater is recommended for the heat recovery wheel to

prevent freezing.

4.6 - DX-coils

•

The DX-coils are supplied without refrigerant.

•

The coils must never be pressurised with water. They

must be sealed and pressurised with a gaseous

medium to prevent pollution of the coil.

•

A qualified person should charge the coil and the rest

of the system with a sufficient amount of the refrigerant

specified in the technical specifications.

•

When connecting the DX-coil to the compressor/

condensing unit always follow the supplier

specifications and the instructions of the qualified

personnel.

•

It is not recommended to connect several DX-coils to

one compressor/condensing unit.

•

It is best to use an infinitely variable controller for the

compressor / condensing unit. If the condensing unit

has infinitely variable control, one of the temperature

controls in the controller can be selected.

•

If the condensing unit does not have infinitely variable

control, set the AHU control for supply air temperature

control, and connect the DX entering temperature

sensor instead of the supply air sensor. The desired

(room) temperature must then be controlled by a

separate controller at the condensing unit.

If a changeover coil is supplied by a heat pump, the

installation must be designed to compensate for the

required heat during the system heat pump defrost cycle

and the heat cannot be drawn from the supply air.

Otherwise the supply air temperature cannot be achieved.

During the heat pump defrost cycle it must be possible to

add so much heat into the system that the desired entering

temperature (heater design capacity) as well as the

required heat for heat pump defrosting can be guaranteed.

AHU with control

To ensure that the correct control strategy for an AHU with

DX-coil can be selected, there is a temperature sensor on

the intake side of the DX-coil. If a heater is placed directly

before the DX-coil, this sensor is only accessible, if an

inspection section is installed between the two coils.

WARNING:

AVOID SPILLING liquid refrigerant on skin or getting it into

the eyes.

USE SAFETY GOGGLES. Wash any spills from the skin

with soap and water. If liquid refrigerant enters the eyes,

IMMEDIATELY FLUSH EYES with water and consult a

physician.

Fill siphon with water, if the fan is switched off.

Negative pressure:

H1 = maximum negative pressure in the cooler section (in mm WG) + 50 mm

H2 = >1/2 x H1

•

Check that the (negative or positive) pressure

corresponds to the siphon type installed.

•

The outlet of the siphon trap connected to the drain

must not be under pressure.

•

It is not recommended to connect a siphon in a

negative pressure section and a siphon in a positive

pressure section via a manifold that is not under

pressure to the drain. Instead two separate manifolds

should be used.

•

If the field-prepared siphon is used, follow the

instructions in the drawing below.