MAINTENANCE

fig. 10

fig. 11

compressor for two minutes and then switch

off the motor and check the oil level; if

necessary fill it up again to the centre of

the warning light

CONDENSATION OUTFLOW

Let the condensation flow out after each

working day through the tap under the tank

(fig. 2). It is advisable to supply the tap with

an automatic drainpipe, to guarantee the

full outflow.

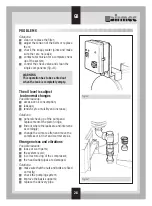

SAFETY VALVE

Control the correct functioning of the safety

valve every 2000 hours of operation. Switch

off the compressor when it has reached a

pressure of 6-7 bar and pull the valve ring

C with strength, without getting near with

the face. Compressed air will be released.

If when releasing it, the ring goes back in

normal position and stops the air outlet, the

valve is perfectly working

(fig. 11).

If otherwise contact a technician for the

replacement.

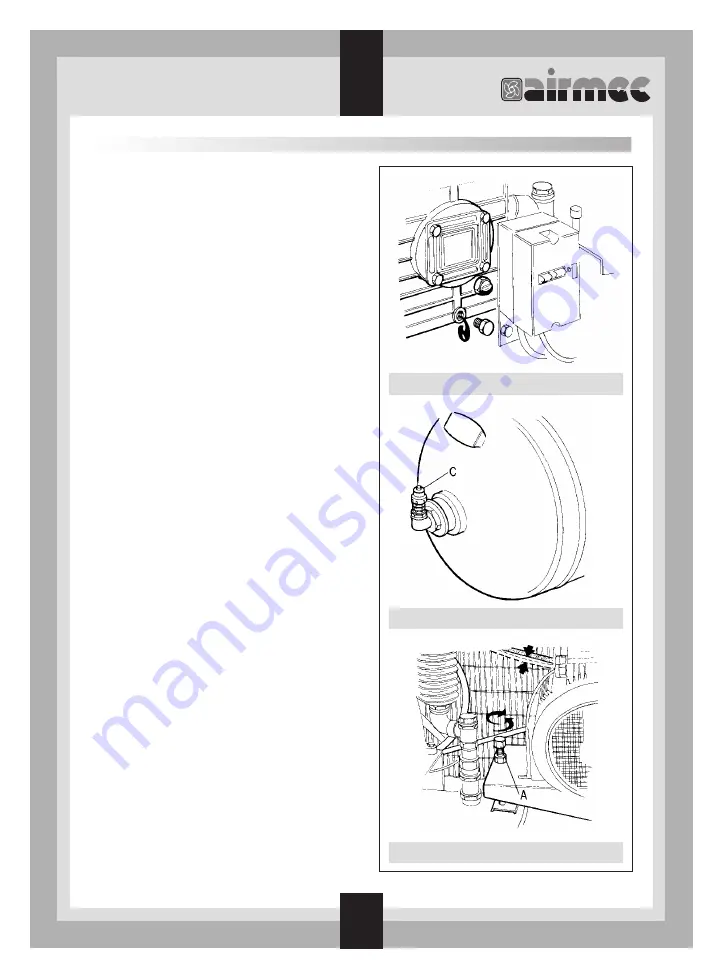

V-BELT

The tension of the V-belts is adjusted by the

supplier. When replacing them it is

necessary to make sure that the driving

plates are correctly positioned and adjust

the tension by manipulating the threaded

pin (A), which rises the motor basis and

enables to adjust the belt tension

(fig. 12).

CONNECTION TO THE ELECTRIC

INSTALLATION

Make sure that the clamps are fixed when

using the compressor for the first time and

then every six months.

GENERAL MAINTENANCE

Blow compressed air onto the compressor

(within the suggested limits) taking care of

the adjustment devices and the motor.

Remove oil deposits.

fig. 12

GB

26

Содержание HOBBY Series

Страница 2: ......

Страница 6: ...INSTALLAZIONE 6 I...

Страница 20: ...INSTALLATION GB 20...

Страница 64: ...007301996 D O C...