2. Maintenance

2-10

2.12

Clean inside of Fuel Tank

●

Condensate is caused and accumulated at the bottom of fuel tank, owing to churning of dust or dirt

mixed when fuel oil is fed and water drop caused while fuel oil tank is used for a long time. When

any condensate is found afloat and fuel filter gets clogged too fast, fuel oil tank should be cleaned

after condensate is removed from fuel oil tank even before the specified cleaning interval time.

<

Procedure

>

①

Open drain valve to remove fuel oil from fuel tank.

②

Dismantle the door and side covers of bonnet.

③

Remove fuel pipes and wires connected to fuel tank.

④

Remove belt holding fuel tank and remove tank.

⑤

Insert cleansing nozzle through fuel filler port or

drain port for cleaning tank.

⑥

After cleaning job is finished, install fuel tank from

which water or the like should be completely removed.

2.13

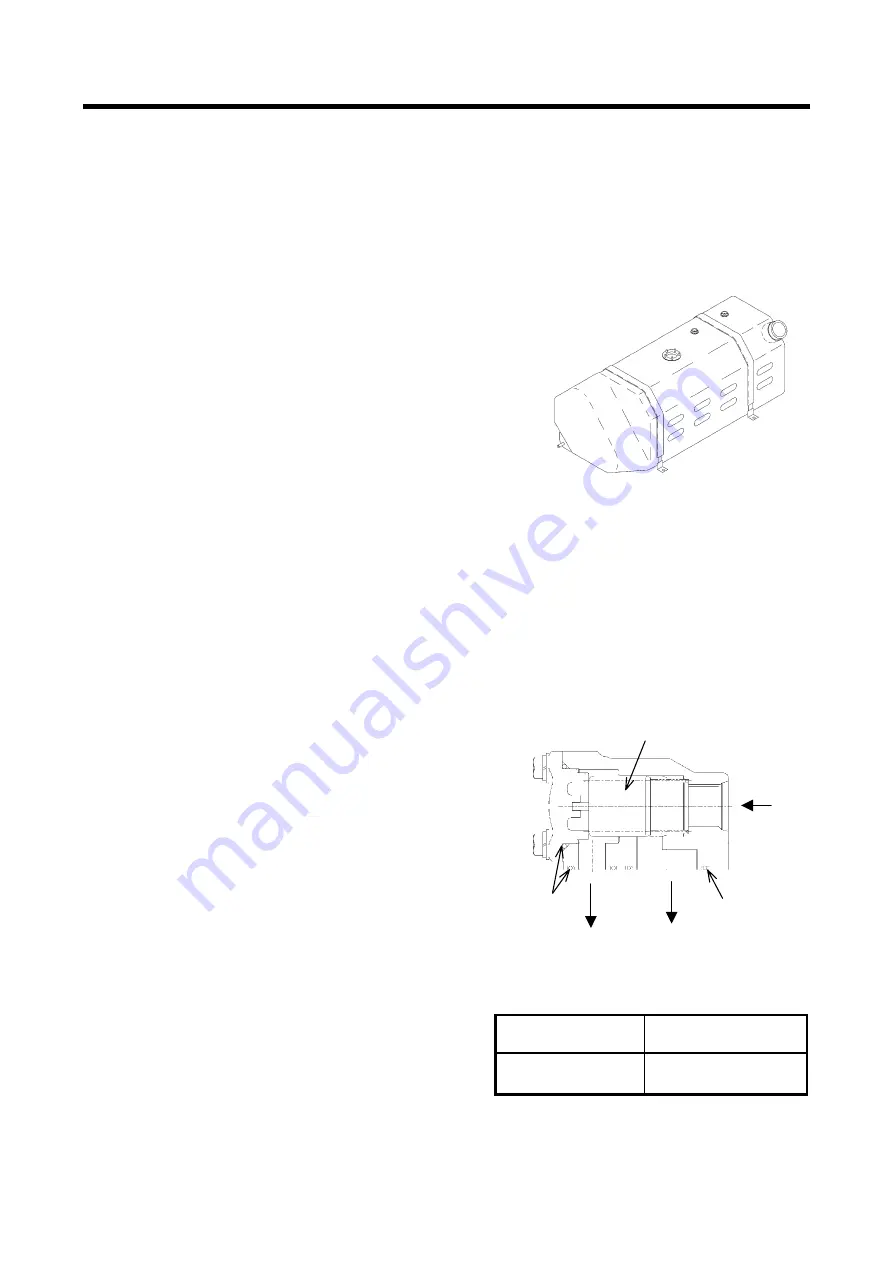

Change of pellet assembly of by-pass valve

●

By-pass valve fitted on this unit is of full bore type. While the unit is used for normal operation, it

is not to perform periodical replacement of the Inner pellet assembly, but when such trouble as

excessive rise of compressor oil temperature, it becomes necessary to replace it, in accordance with

the following procedures.

<

Procedure

>

①

First stop the unit and make sure that there is no

residual pressure left in the separator receiver tank.

②

After checking and confirming that the temperature

of compressor oil has become amply low, open drain

valves on separator receiver tank and oil cooler to

empty compressor oil completely.

③

After having drained oil completely, remove the pellet

assembly of by-pass valve and O-ring.

④

Replace the pellet assembly and O-ring by new ones.

Install O-ring coated thinly with compressor oil.

⑤

Supply compressor oil through the filler port provided

on the receiver tank. (Refer to operation manual.)

⑥

Start operation and check the function of by-pass

valve. (It functions well when delivery air

temperature will not rise abnormally.)

To Oil filter

(When oil

temperature is low)

Pellet ASS’Y

To oil cooler

(When oil temperature

is high)

O-ring

From separator

receiver tank

O-ring

PC08023

Actuating

temperature

By-pass valve fully

closing temperature

180

±

37°F

(82

±

3

℃

)

192

±

36°F

(89

±

2

℃

)

PC08022

Discount-Equipment.com

Содержание PDS185S-6C1

Страница 1: ...D i s c o u n t E q u i p m e n t c o m...

Страница 9: ...1 Specification 1 5 A070356 Unit mm PDS185S 6C1 VE PUMP Type D i s c o u n t E q u i p m e n t c o m...

Страница 10: ...1 Specification 1 6 PDS185S 6C1R IN LINE PUMP Type A070195E Unit mm D i s c o u n t E q u i p m e n t c o m...

Страница 19: ...1 Specification 1 15 1 7 Piping Diagram PC08091E D i s c o u n t E q u i p m e n t c o m...

Страница 20: ...1 Specification 1 16 1 8 Fuel piping PDS185S 6C1 VE PUMP Type PC08018E D i s c o u n t E q u i p m e n t c o m...

Страница 21: ...1 Specification 1 17 PDS185S 6C1R IN LINE PUMP Type PC08019 1E D i s c o u n t E q u i p m e n t c o m...

Страница 37: ...3 Electric System 3 5 2 PDS185S 6C1R IN LINE PUMP Type PC08028E D i s c o u n t E q u i p m e n t c o m...

Страница 38: ...3 Electric System 3 6 2 Function timing upon starting PC08029E D i s c o u n t E q u i p m e n t c o m...

Страница 75: ...5 3 5 2 Engine Wiring Diagram PDS185S 6C1 VE PUMP Type PC08046E D i s c o u n t E q u i p m e n t c o m...

Страница 76: ...5 4 PDS185S 6C1 VE PUMP Type PC08047E D i s c o u n t E q u i p m e n t c o m...

Страница 77: ...5 5 PDS185S 6C1R IN LINE PUMP Type PC08048E D i s c o u n t E q u i p m e n t c o m...

Страница 78: ...5 6 PDS185S 6C1R IN LINE PUMP Type PC08090E D i s c o u n t E q u i p m e n t c o m...

Страница 79: ...D i s c o u n t E q u i p m e n t c o m...