40

VI. Water Piping and Trim

A. Factory Supplied Piping and Trim (continued)

b. Install close nipple into tee branch. Then, screw

the assembly into boiler left side ¾ in. front

tapping, making sure tee run outlet is in vertical

plane and parallel to boiler side.

c. Install the ¾ in. NPT x 12 in. black nipple into

tee top run outlet.

d. Mount ¾ in. FPT x 1 in. FPT safety relief valve

onto 12 in. nipple.

e. Install drain valve into tee bottom run outlet.

f. Locate and remove 2 in. NPT steel coupling,

(2) 2 in. NPT x 2-1/2 in. long black nipples, 2

in. x 2 in. x ½ in. NPT black tee, 2 in. x 2 in. x

1 in. NPT black tee, packaged flow switch with

paddles, and temperature & pressure gauge.

g. Mount 2 in. NPT coupling onto 2 in. MPT boiler

supply tapping (see Figure 1C). Then, install 2

in. NPT x 2-1/2 in. long black nipple into the

coupling outlet. Attach 2 in. x 2 in. x ½ in. tee

onto the nipple opposite end, making sure ½ in.

branch outlet is in horizontal plane and facing

the boiler front.

h. Install temperature & pressure gauge into the tee

branch.

i. Install second 2 in. NPT x 2½ in. long nipple into

2 in. x 2 in. x 1/2 in. NPT tee run.

j. Mount 2 in. x 2 in. x 1 in. NPT black tee onto the

nipple, making sure tee 1 in. NPT branch outlet

is oriented upward.

k. Remove flow switch and paddles from packaging

carton. Also see/follow Taco Instruction Sheet

for Flow Switch Kit (supplied with flow switch)

for specific details.

l. Select paddle stamped “1” for APX825.

m. Attach paddle to flow switch stem using supplied

machine screw.

n. Apply pipe dope to the switch-threaded brass-

bushing end. Then, mount the switch threaded

end with the attached paddle into 2 in. x 2 in.

x 1 in. NPT tee branch and tighten such that

distance between bottom of switch housing and

top of tee branch is approximately 1-11/16 in.

(43 mm). Insure the switch paddle is positioned

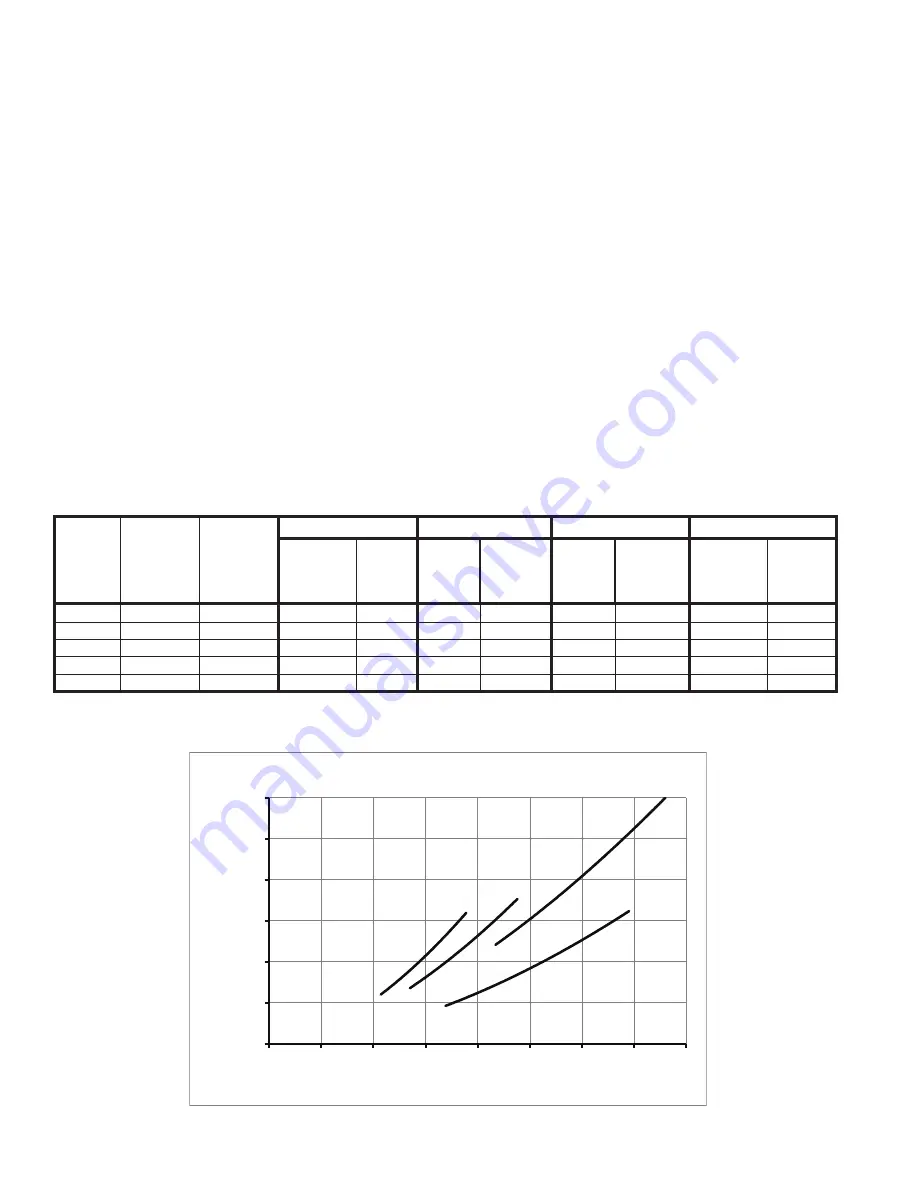

Boiler

Model

Supply

Connection

(in.)

Return

Connection

(in.)

ΔT

= 35°F

ΔT

= 30°F

ΔT

= 25°F

ΔT

= 20°F

Minimum

Required

Flow (GPM)

Boiler

Head

Loss (ft.)

Required

Flow

(GPM)

Boiler

Head Loss

(ft.)

Required

Flow

(GPM)

Boiler

Head Loss

(ft.)

Maximum

Required

Flow

(GPM)

Boiler

Head

Loss (ft.)

APX425

1-1/2

1-1/2

21.5

6.1

25.1

7.9

30.2

10.8

37.7

15.9

APX525

1-1/2

1-1/2

27.1

6.9

31.7

8.9

38.0

12.1

47.5

17.6

APX625

2

2

33.9

4.7

39.6

6.1

47.5

8.4

59.4

12.4

APX725

2

2

39.4

6.0

45.9

7.9

55.1

10.9

68.9

16.1

APX825

2

2

43.4

12.1

50.7

15.5

60.8

20.9

76.0

30.0

Notes: Required Flow = Output*1000/(500*ΔT), where flow rate is in GPM, output is in MBH, and ΔT is in °F

Outputs for specific boiler models are provided in Table 2.

See also Tables 13 A and 13B for near boiler piping sizing.

Using boiler antifreeze will result in increased fluid density and may require larger circulators.

Table 12: Flow Range Requirement Through Boiler

0

5

10

15

20

25

30

0

10

20

30

40

50

60

70

80

Head

Loss

(ft.)

Water Flow Rate (GPM)

Boiler Head Loss

425

525

825

625/725

Содержание APEX

Страница 6: ...6 I Product Description Specifications and Dimensional Data continued Figure 1A Apex Model APX425 ...

Страница 7: ...7 Figure 1B Apex Model APX525 I Product Description Specifications and Dimensional Data continued ...

Страница 9: ...9 I Product Description Specifications and Dimensional Data continued Figure 1D Apex Model APX825 ...

Страница 57: ...57 VIII Electrical continued Figure 26 Ladder Diagram ...

Страница 58: ...58 VIII Electrical continued ...

Страница 59: ...59 Figure 27 Wiring Connections Diagram VIII Electrical continued ...

Страница 68: ...68 IX System Start up continued Apex Series Operating Instructions Figure 34 Operating Instructions ...

Страница 105: ...105 ...

Страница 109: ...109 XIII Repair Parts continued APX625 APX725 and APX825 APX825 shown ...

Страница 112: ...112 XIII Repair Parts continued APX425 and APX525 ...

Страница 114: ...114 XIII Repair Parts continued APX625 APX725 and APX825 ...

Страница 122: ...122 ...

Страница 123: ...123 ...