12

Specifications and Need

-

to

-

Know Information

alphaTIG 203Xi

cumstances should you attempt to modify or make unauthorized

changes to the welder or its programming. To do so will void the war-

ranty.

HF Point Gap Maintenance

This unit is equipped with adjustable high frequency points

that generate the High Frequency Voltage to create the

touchless HF start of the unit. Occasionally, adjustment

may be needed, particularly in the first few months of oper-

ation, and periodically thereafter. This is a simple adjustment after

you

’

ve done it once or twice. The point gap should be set between

0.029”

to

.040”

for best operation. The target point gap should be

between

.030”

and

.035”.

A point gap that is too small may cause

weak starts. A point gap that is too wide may cause electrical inter-

ference with surrounding equipment and electronic items.

The location of the points can be identified by quickly pressing the

torch switch/foot pedal while looking up through the front vents of

the welder. The points should arc briefly. If they do not, they may

only need adjustment or cleaning. (But if after adjustment they do

not fire, contact Ahp technical support at the number listed on the

front of this manual.) If you do not see the arc location, look up and

to the left of the unit. There will be a small board with a brass and

black plastic holder along with carbon contacts in them. They will be

located on a small square board with a couple rows of small capaci-

tors and a coil/transformer on the same board.

To gain access to the points and adjust them, follow steps

1

–

6

on

the previous page. You will need a small jeweler

’

s or mechanic

’

s

screwdriver, and small ignition wrench and a feeler gauge to set the

points. Do not overtighten the jam nut securing the adjustment

screw. Hold the screwdriver in place on the screw while tightening

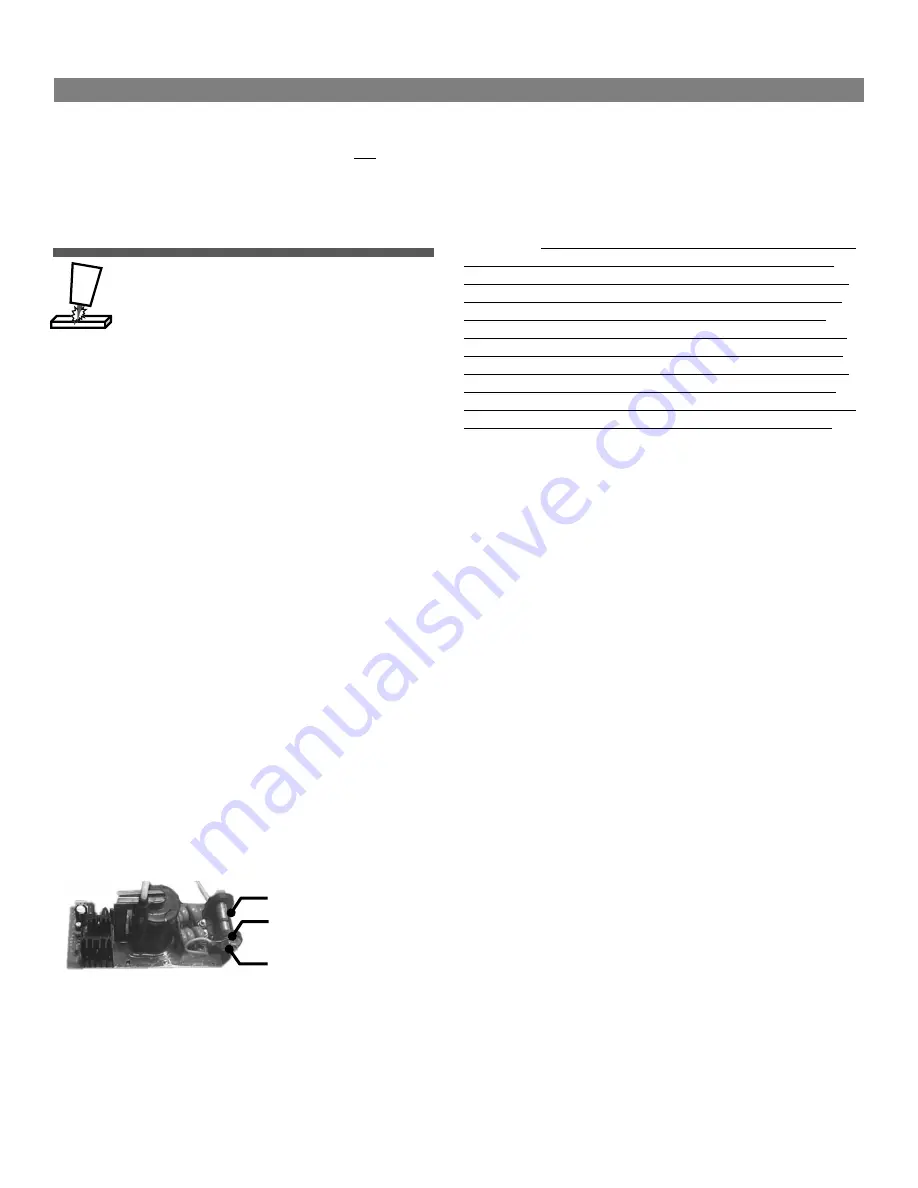

the jam nut with an ignition wrench. See the image below.

The board in the image below is shown inverted for demonstration

purposes and is removed from the unit. Removal is not necessary. The

points will be in the

“

hanging

”

position and can be adjusted through

the left side of the machine. (Whole board is not pictured.)

For more detailed written and illustrated directions on how to locate

and adjust the point gap, contact Ahp technical support.

NOTICE:

Point Gap adjustment is a part of regular maintenance and

is a normal responsibility of the customer. Point gap adjustment and

normal cleaning/maintenance does not fall under the warranty terms

for this welder. If you have any issues or questions concerning point

gap adjustment, call or contact Ahp tech support before attempting

the adjustment. The HF system used in this unit is only used for

starting the arc. They do not stay on while welding in DC or in AC.

They have no effect other than arc starting efficiency. Inverters

switch so quickly in AC that HF is not needed to maintain a stable arc.

IMPORTANT:

Do not needlessly adjust the point gap in order to try to

resolve operational issues not related directly to arc starting. Arc

starting is the only purpose of the HF points inside this unit. Before

assuming you have an HF starting issue, check the work clamp, the

work clamp cable and connections under the rubber boot on the

DINSE connector to make sure the connections are tight, and corro-

sion free. Connect the work clamp directly to a freshly ground spot

on the work piece and attempt to weld before assuming you have an

HF point gap issue. Also make sure polarity is correct. Most com-

monly, a poor connection to the work piece, corrosion or wrong polar-

ity is the cause of poor arc starting rather than a point gap issue.

Other items that may also cause poor arc starting:

•

Wrong shielding gas, or not enough flow.

•

Too much gas flow creating turbulence.

•

Welder is too close to the weld area and fans are blowing gas

coverage off weld. Move to 6

-

8 feet away.

•

Dirty or contaminated metal Preclean aluminum with Stainless

brush or special aluminum grinding wheel. Decontaminate with

acetone or aluminum cleaner made specifically for welding Alu-

minum. Grind steel with hard stone on grinder. Refrain from

using flap disks which often polish the mill scale rather than

remove it.

•

Too long of an arc gap between tungsten and metal.

•

Too much stick

-

out of the Tungsten, not enough shielding gas

flowing around Tungsten.

•

No Pre

-

Flow. Set to .3 to .5 Seconds.

•

Wrong Tungsten. Use Lanthanated or Ceriated Tungsten for all

processes. Do not use pure, or zirconiated types of Tungsten.

Use caution when trying new or proprietary

“

blends

”.

Often

these have poor quality control.

•

Work Clamp is not connected directly to what is being welded.

•

Work clamp, cable, or connector is corroded or bad. Check all

connections, including where the cable attaches to the DINSE

type connector. (You must pull rubber boot back).

•

Dirty Tungsten. This is often indicated by a green flare or spit-

ting while starting the arc or while welding.

HF Point Gap Location

Locking Nut

Adjustment Screw

Содержание alphaTIG 203Xi

Страница 32: ...32 ...