20

2.

Replace the annular cutter arbor and carefully tighten the bolts evenly to ensure proper alignment.

WARNING: use extreme care to avoid contacting the rotating arbor shaft!

3.

Double check to ensure that there is no binding anywhere throughout the stroke.

NOTE: A pilot hole may be necessary when drilling with larger twist drills. If a MT3 twist drill is used, it

may not be necessary to remove the arbor support bracket.

CHUCK

If a MT3 chuck adaptor & chuck are used, then the bracket must be removed.

To replace, see the instructions above under

“ARBOR SUPPORT BRACKET REPLACEMENT”.

TAPPING

CAUTION: To avoid damage to the tap, always very carefully line the tap up with the hole and ensure

that the size of the hole is correct for the tap to be used.

CAUTION: To avoid damage to the tap or machine, be very careful to stop the machine in time to NOT

allow the tap bottom out. The motor continues to coast for a while after being shut off, so plan for this

and anticipate. This machine does NOT have a tapping clutch.

CAUTION: To avoid damage to the machine, ALWAYS allow the machine to come to a full stop before

reversing rotation.

1.

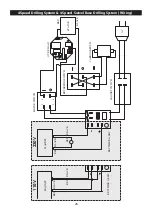

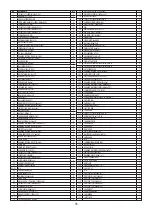

Select the proper speed according to the chart for the size of tap used.

2.

Begin with forward direction of rotation with standard right hand threads.

(Opposite with left-hand threads)

3.

Allow the tap to determine the feed rate. A light touch on the feed handle is all

that is needed once it is started in the hole.4. When the desired thread is

tapped, hit the red motor stop switch. Allow the machine to come to a full

stop. Then reverse direction and restart machine by pressing the green motor

switch to remove tap. Guide the tap back out with the feed handle. Proper

order of operations for normal tapping is as follows:

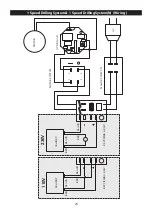

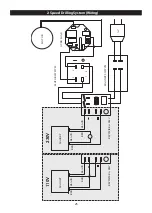

magnet: on. direction: forward. motor: on.

motor: off. THEN: direction: reverse. motor: on. motor: off - magnet: off.

MAINTENANCE

Every 50 hours of operation blow compressed air through the motor while running at no load to clean out

accumulated dust. (If operating in especially dusty conditions, perform this operation more often.)

1.

Keep the machine clean and free of chips.

2.

Check for loose fittings and tighten as needed.

Содержание MD120/4

Страница 44: ......