17

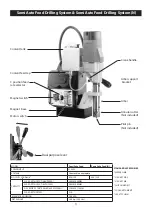

OPERATION

The operation instructions under “OPERATION-GENERAL” also apply to this

machine. Please see the additional instructions specific to the 4-speed Morse

taper model below:

WARNING: NEVER operate 60mm (2-3/8 in.) or larger cutters unless the plate

thickness is mini mum 20mm (13/16 in.) MAGNET LIFTING MAY RESULT. If

the plate thickness is not enough, supplement the magnetic adhesion by

adding a 10mm or thicker plate directly the magnet’s position under the

work piece.

CAUTION: Machine is equipped with a reversing switch. Always ensure that

direction of rotation is correct before operating. Operating in the wrong

direction could result in damage to the cutter.

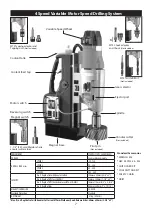

Select desired gear range by first popping the tab out of its detent and then sliding selectors up or down in

the proper combination. Refer to the chart to achieve the correct combination for the desired speed. (It may

be necessary to turn the arbor slightly in order for the gears to mesh properly). Follow the recommended

speed ranges on the cutting speed chart to set the proper speed and gear range.

NOTE: These speeds are general recommendations only. The material should determine actual speeds

and the cutting speed recommended by the cutting tool manufacturer. See the section below

"RECOMMENDED SURFACE SPEEDS" and use the formula to calculate the best RPM.

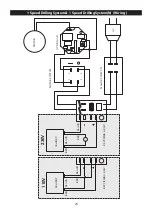

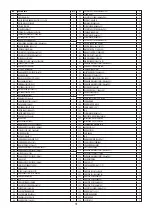

4 SPEED GEAR CHART (FIXED MOTOR SPEED MODELS)

GEAR NO LOAD min

-1

FULL LOAD min

-1

CUTTERS TAPS

1

150

90

60~75mm 15~25.4mm or less

(2-3/8 to 3 in.) (9/16 to 1 in.)

2

200

120

45~60mm N/A

(1-3/4 to 2-3/8 in.)

3

300

180

35~45mm N/A

(1-3/8 to 1-3/4 in.)

4

380 230

35mm or less

N/A

(1-3/8 in.)

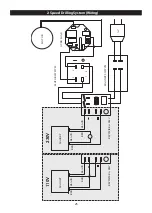

4 SPEED GEAR CHART (VARIABLE MOTOR SPEED MODELS)

GEAR

MAX. SPEED min

-1

MIN. SPEED min

-1

CUTTERS TAPS

1

120 35

Up to 120mm

25mm or less

(4-3/4") ( 1 in.)

2

220

70

55mm-70mm

N/A

(2-1/8 to 2-3/4 in.)

3

250

80

35~55mm N/A

(1-3/8 to 2-1/8 in.)

4

450

140

35mm or less

N/A

(1-3/8 in.)

Содержание MD120/4

Страница 44: ......