ROBOTAPE 50 ME - LH

3. TECHNICAL INFORMATION

3.1. MACHINE GENERAL DESCRIPTION

‒

The semi-automatic manually adjustable taper is a machine designed and built to close products

contained in carton boxes of various formats with adhesive tape.

‒

Use machine only for the purposes set forth by the manufacturer. improper use of machine can cause

risks to safety and health of persons, further to economical damage.

‒

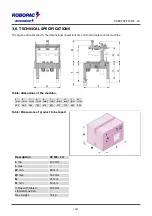

The machine enables sealing small casings with the dimensions indicated in chapt.

3.6.

“Technical

specifications”.

‒

It can house two taping units

T50 - LH

that use wide adhesive tape rolls

25÷38 mm

, available on the

market.

‒

The packs that contain liquids or insubstantial materials must be suitable for the product and must be

perfectly closed and tight in order to prevent any leaks of the content.

‒

It is equipped with a series of safety devices designed to avoid anyharm befalling the operator or other

persons who come into contactwith the machine in any way. The machine is produced in a range

ofdifferent models in order to suit market requirements.

‒

This machine is normally installed in workshops or industrial environments protected from the

atmospheric agents.

Use of this machine in explosive environments or when exposed to the elements is strictly

forbidden.

‒

Just one worker is necessary for operation that provides to loading and unloading of the boxes, reel

replacement and to the format change stages.

The figure shows, as a reference only, the machine models and the tablesshow the data and the main

specifications.

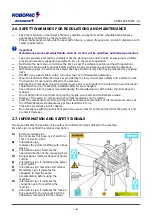

Main parts

A)

Base.

B)

Transport unit:

It transports the box during the taping phase

and aligns it in the middle of the taping units.

C)

Bottom taping unit:

Accomplishes the taping operation of the

bottom part of the box.

D)

Top taping unit:

Accomplishes the taping operation of the top

part of the box.

E)

Lifting table:

It places the top taping unit at boxes height.

F)

Side pressure units:

Position the box at the centre of the taping unit.

G)

Electric panel.

13/43