MAINTENANCE

NOTE

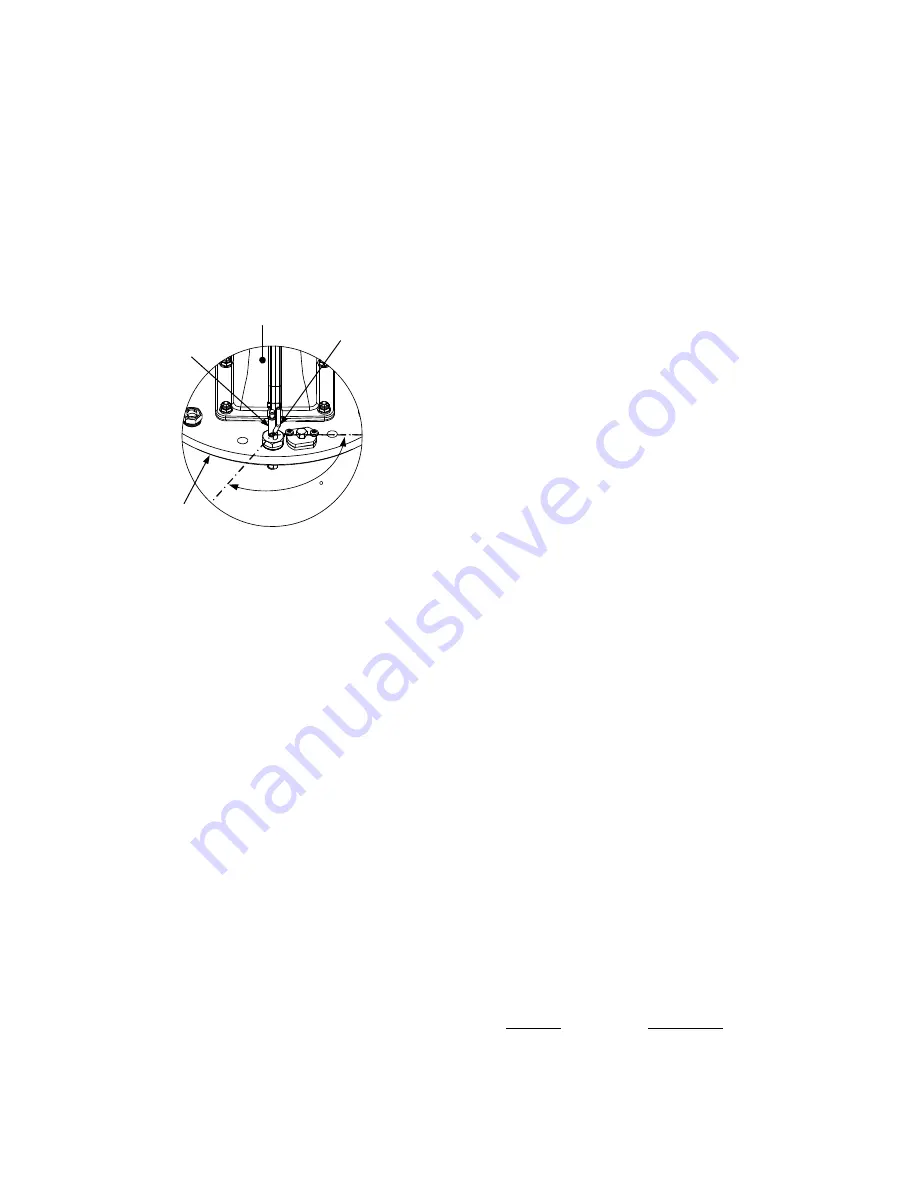

If a replacement ignitor-injector (part no.

58023) is being installed, a compression

nut containing a built-in ferrule will be

included with the replacement part. If

needed, 3 indexing washers are also

included These washers may be needed

to properly position the gas injector tube

of the ignitor-injector within the 120° angle

shown in Figure 7-3.

12

0

IGNITOR-

INJECTOR

GAS

INJECTOR

TUBE

BLOWER

BURNER

PLATE

Figure 7-3

Ignitor-Injector Orientation

8. Reinstall the ignitor-injector in the burner

plate. Torque to 15 ft-lbs. Do not over

tighten.

9. Connect the staged ignition assembly to the

gas injector tube of the ignitor-injector by

securing the compression nut to the elbow

of the staged ignition assembly.

10. Reconnect the ignitor-injector cable.

11. Reinstall the side and top panels on the unit.

7.3 FLAME DETECTOR

The flame detector (part no. 66006) is located

on the burner plate at the top of the unit (see

Figures 7-1 and 7-2). The flame detector may be

hot. Allow the unit to cool sufficiently before

removing the flame detector.

To inspect or replace the flame detector:

1. Set

the

ON/OFF

switch on the control panel,

to the

OFF

position. Disconnect AC power

from the unit.

2. Remove the side and top panels from the

unit.

3. Disconnect the lead wire from the flame

detector.

4. Remove the two (2) screws securing the

flame detector to the plate (Figure 7-2). The

flame detector is secured to the burner plate

with one (1) #10-32 screw and one (1) #8-32

screw.

5. Remove the flame detector and gasket from

the burner plate.

6. Thoroughly inspect the detector. If eroded,

the detector should be replaced. Otherwise

clean the detector with a fine emery cloth.

7. Reinstall the flame detector and flame

detector gasket.

8. Reconnect the flame detector lead wire.

9. Reinstall the side and top panels on the unit.

7.4 COMBUSTION CALIBRATION

Combustion settings must be checked at the

intervals shown in Table 7-1 as part of the

maintenance requirements. Refer to Chapter 4

for combustion calibration instructions.

7.5 SAFETY DEVICE TESTING

Systematic and thorough tests of the operating

and safety devices should be performed to

ensure that they are operating as designed.

Certain code requirements, such as ASME

CSD-1, require that these tests be performed on

a scheduled basis. Test schedules must

conform to local jurisdictions. The results of the

tests should be recorded in a log book. See

Chapter 6-Safety Device Testing Procedures.

7.6 BURNER ASSEMBLY INSPECTION

The burner assembly (part no. 24176) is located

at the top of the unit's heat exchanger. The

burner assembly may be hot. Therefore, allow

the unit to cool sufficiently before removing the

burner assembly. It should be noted that the

complete burner assembly also includes the

blower and air/fuel valve in addition to the

Benchmark 2.0 Low NOx burner.

The following parts will be necessary for

reassembly after inspection:

Part No.

Description

81101

Burner Gaskets (2)

81048

Flame Detector Gasket

81068

Blower Gasket

7-3

Содержание Benchmark 2.0

Страница 4: ......

Страница 8: ......

Страница 12: ......

Страница 24: ......

Страница 44: ......

Страница 50: ......

Страница 78: ......

Страница 84: ......

Страница 88: ......

Страница 90: ......

Страница 101: ...APPENDIX F F 5 ...

Страница 102: ...APPENDIX F F 6 ...

Страница 104: ...APPENDIX F F 8 ...

Страница 105: ...APPENDIX F F 9 ...

Страница 106: ...APPENDIX F F 10 ...

Страница 107: ...APPENDIX F F 11 ...

Страница 108: ...APPENDIX F F 12 ...

Страница 112: ...APPENDIX G G 4 ...

Страница 113: ...APPENDIX H H 1 ...

Страница 114: ...APPENDIX H H 2 ...

Страница 115: ...APPENDIX H H 3 ...

Страница 118: ......

Страница 119: ...APPENDIX J BENCHMARK CONTROL PANEL EXPLODED VIEW J 1 ...

Страница 120: ...APPENDIX J J 2 P1 P2 P3 P4 P5 P6 BENCHMARK CONTROL PANEL REAR VIEW ...

Страница 122: ......