PS QuarterHorse Series Chillers

Page 23

7

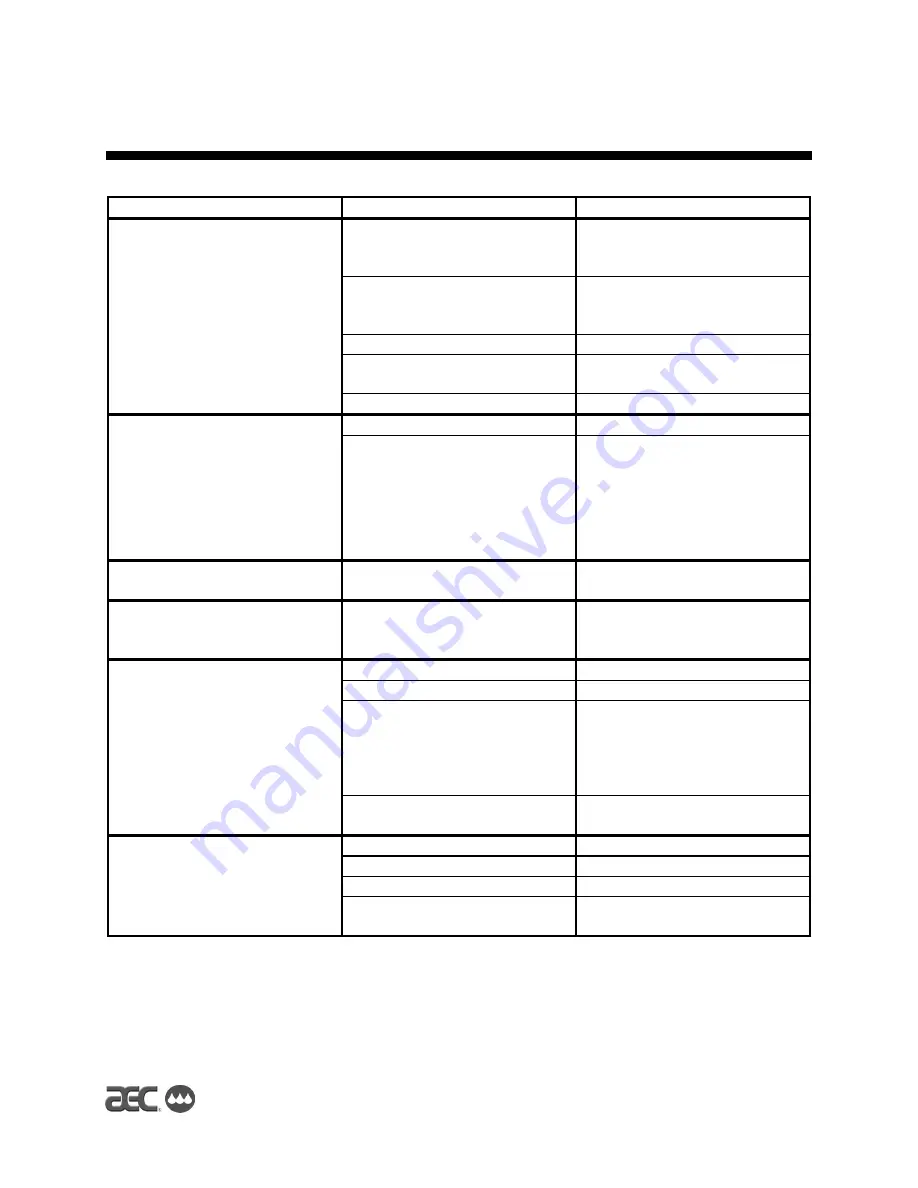

Troubleshooting Guide

Problem

Possible cause

Solution

No power.

Check main disconnect

fuses, wiring, and power lead

to the unit.

Wrong voltage supplied to

the chiller.

Voltage must be within plus

or minus 10% of the

nameplate rating.

Defective on/off switch.

Replace.

Control circuit fuse blown.

Replace, check the

transformer.

Chiller will not run.

Defective control transformer. Replace.

Refrigerant is low.

Check the refrigerant charge.

The leaving water

temperature is too high.

Improper water/glycol

solution.

Make sure that the coolant

solution is right for the

process — must be 75%

water and 25% glycol.

See Figure 3 on Page 13 for

more information.

Pump pressure is low

(see pump curve).

Check for foreign matter.

Clean the system.

Pump pressure is too high.

Restricted water flow.

Check for partially closed

valves, etc. Be sure all lines

are properly sized.

Refrigerant is low.

Check the refrigerant charge.

Defective fan motor.

Repair or replace.

Compressor internal overload

is open. Allow time to cool

and reset.

Check for high/low voltage.

Must be within plus or minus

10% of the nameplate rating.

Check for poor compressor

electrical connections.

Pump runs, compressor will

not.

Broken wire in the

compressor control circuit.

Locate and repair.

Restricted condenser airflow.

Clean the condenser.

Unit low on refrigerant.

Call Service.

Inefficient compressor.

Call Service.

Unit runs continuously, but

not enough cooling power.

Unit undersized for

application.

Call Sales Representative.

Содержание QuarterHorse Series 0.25 Portable Chiller PS-025

Страница 1: ...PS 025 QuarterHorse Series 0 25 hp Portable Chiller Operation and Installation Manual...

Страница 16: ...Page 16 PS QuarterHorse Series Chillers Notes...

Страница 17: ...PS 025 QuarterHorse Series 0 25 hp Portable Chiller Operation and Installation Manual...

Страница 18: ...Page 18 PS QuarterHorse Series Chillers Notes...

Страница 20: ...Page 20 PS QuarterHorse Series Chillers Notes...

Страница 22: ...Page 22 PS QuarterHorse Series Chillers Notes...

Страница 24: ...Page 24 PS QuarterHorse Series Chillers Service Notes...

Страница 25: ...PS QuarterHorse Series Chillers Page 25 Service Notes...

Страница 28: ...801 AEC Drive Wood Dale IL 60191 1198 USA 630 595 1060 Fax 630 595 6641 http www aecinternet com...