PS QuarterHorse Series Chillers

Page 13

;

If you want to use straight water, contact Application Engineering’s,

Engineering Department.

;

The 1 gallon (3.8 liter) reservoir is

not

designed to withstand water pressure

above 5 psi (34 kPa).

;

The fill opening and vent line must be vented to the atmosphere for proper

operation.

Properly Venting and Filling the Reservoir Tank

To properly vent and fill the tank:

•

Remove the side panel, then remove the bushing installed on the top of the

tank.

•

Install a pipe nipple and tee to the ¾” coupling on top of the tank.

•

Use one side of the tee for the vent line and the other side for the fill line.

•

Fill the tank.

•

Remove the fittings and re-install the bushing

•

Extend the vent line from the tank to a proper drain.

•

Re-install the side panel.

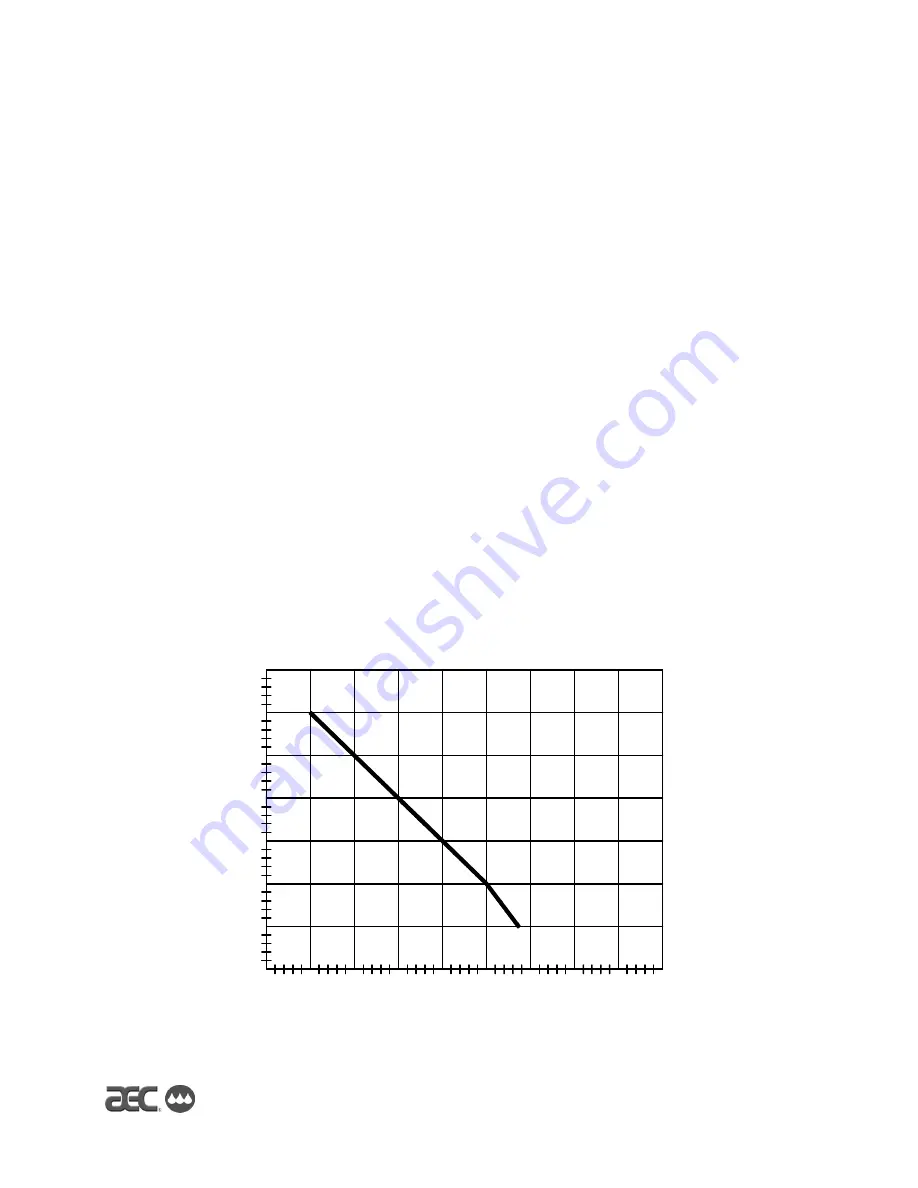

Figure 3

Ethylene Glycol Curve

Ethylene glycol required

Normal operating range is between 30°F and 70°F

for evaporator freeze protection

Chilled water

operating temperature °F

(set point)

10%

20%

30%

Ethylene

glycol

percent

by

volume

0%

0º

30º

40º

50º

60º

70º

Содержание QuarterHorse Series 0.25 Portable Chiller PS-025

Страница 1: ...PS 025 QuarterHorse Series 0 25 hp Portable Chiller Operation and Installation Manual...

Страница 16: ...Page 16 PS QuarterHorse Series Chillers Notes...

Страница 17: ...PS 025 QuarterHorse Series 0 25 hp Portable Chiller Operation and Installation Manual...

Страница 18: ...Page 18 PS QuarterHorse Series Chillers Notes...

Страница 20: ...Page 20 PS QuarterHorse Series Chillers Notes...

Страница 22: ...Page 22 PS QuarterHorse Series Chillers Notes...

Страница 24: ...Page 24 PS QuarterHorse Series Chillers Service Notes...

Страница 25: ...PS QuarterHorse Series Chillers Page 25 Service Notes...

Страница 28: ...801 AEC Drive Wood Dale IL 60191 1198 USA 630 595 1060 Fax 630 595 6641 http www aecinternet com...