A-16 / ENGLISH

A-16

- FORM NO. - 56041972 - Warrior

™

ST, Warrior

™

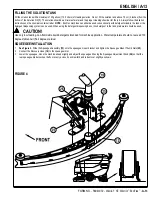

EcoFlex

™

WET SCRUBBING

WARNING!

Be sure you understand the operator controls and their functions. While on ramps or inclines, avoid sudden stops when loaded.

Avoid abrupt sharp turns. Use low speed down hills. Clean only while ascending (driving up) the ramp.

1

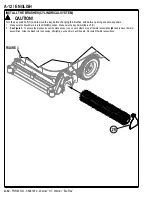

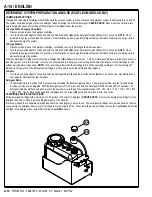

Follow the instructions in the Preparing The Machine For Use section of this manual.

2

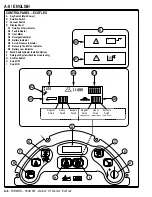

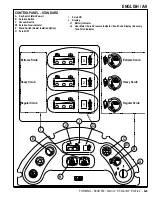

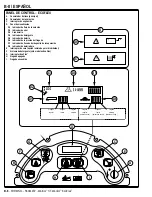

Turn the Master Key Switch

(A)

ON (I). This will display the control panel indicator lights, reference the Battery Indicator and Hour Meter on the Display

(D or J)

.

3

To transport the machine to the work area, push the Drive Paddle

(34)

forward to go forward or pull the Drive Paddle

(34)

backward to move the machine in reverse. Vary the

pressure on the Drive Paddle

(34)

to obtain the desired speed.

NOTE:

Speed Control Knob

(35)

is used to control the maximum speed in either forward or reverse.

4

Press and hold the Solution Switch

(B)

for 5 seconds to pre-wet the

À

oor.

NOTE:

This must be done prior to pressing the Scrub ON Switch

(I)

.

5

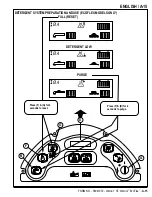

Press the Scrub ON Switch

(I)

once for Regular Scrub or twice for Heavy Scrub mode. Hold this switch for 5 seconds for Extreme Scrub mode. Both the solution system

and detergent system have 3

À

ow rate presets that coincide with the 3 scrub modes (see Control Panel).

NOTE:

There is a solution

À

ow rate over ride function if you wish

to increase solution

À

ow without increasing scrub pressure. Hold the Solution Switch

(B)

for 3 seconds (solution indicator will start

À

ashing) and then let go. You then have 3

seconds to set a different

À

ow rate by simply pressing the Solution Switch

(B)

repeatedly until the Solution Flow Rate Indicator

(D1)

shows the rate you desire (Regular, Heavy or

Extreme / see Control Panel). Any subsequent scrub pressure adjustments will reset the solution

À

ow rate to default.

NOTE:

The solution, vacuum and detergent (EcoFlex models) systems are automatically activated when the Scrub ON Switch

(I)

is pressed. No further action is required other

than lowering the squeegee

(17)

. Any individual system can be turned OFF or back ON by simply pressing its switch at any time during scrubbing.

6

Lower the squeegee with the Squeegee Raise / Lower Lever

(17)

.

7

When the Drive Paddle

(34)

is in the neutral position, the scrub, vacuum, solution and detergent (EcoFlex models) systems are activated but not running. Grip the Operator

Control Handle

(2)

and push the Drive Paddle

(34)

forward to start the scrub, vacuum, solution and detergent (EcoFlex models), and to move the machine forward. For best

results, move the machine at a slow walking speed. Press the Solution Switch

(B)

once to turn OFF while making sharp turns. Pull the Drive Paddle

(34)

backward to move the

machine in reverse. The brushes will run while moving the machine in reverse, but solution and chemical will not be dispensed.

CAUTION!

To avoid damaging the

À

oor, keep the machine moving while the brushes are turning.

8

When scrubbing, check behind the machine occasionally to see that all of the waste water is being picked up. If there is water trailing the machine, you may be dispensing too

much solution, the recovery tank may be full, or the squeegee tool may require adjustment.

9

EcoFlex models only:

The machine defaults to the EcoFlex cleaning mode (EcoFlex Switch Indicator is lit GREEN) conserving solution and detergent. Press the EcoFlex

Switch

(G)

to override the EcoFlex cleaning mode and temporarily increase scrub pressure, solution

À

ow and the detergent ratio. This will cause the indicator to

À

ash green for

one minute, solution

À

ow rate will increase to the next level, scrub pressure will increase to the next level and the detergent ratio will increase to the pre-programmed ratio. The

pre-programmed ratio that is used during EcoFlex override can be adjusted. With the detergent system OFF, press and hold the Detergent ON/OFF Switch

(F)

for 2 seconds.

The detergent indicator will

À

ash and each press of the switch will cycle through the available ratios

(1:32, 1:50, 1:64, 1:100, 1:128, 1:150, 1:200, 1:256, 1:300, 1:400)

.

Once the desired ratio is displayed on the screen

(D4)

, stop and it will lock in after 5 seconds.

NOTE:

Pressing and holding the EcoFlex Switch

(G)

for 2 seconds disables the EcoFlex system. The only way to re-enable is to push the EcoFlex Switch

(G)

again. Cycling

the Key Switch

(A)

does not re-enable the system. The EcoFlex system will only function if the Scrub System

(I)

has been enabled.

10

For extremely dirty

À

oors, a one-pass scrubbing operation may not be satisfactory and a “double-scrub” operation may be required. This operation is the same as a one-pass

scrubbing except on the

¿

rst pass the squeegee is in the up position. This allows the cleaning solution to remain on the

À

oor to work longer. The

¿

nal pass is made over the

same area, with the squeegee lowered to pick up the accumulated solution.

11

The recovery tank has an automatic shut-off switch that turns ALL systems OFF except the drive system when the recovery tank is full. When this switch is activated, the

recovery tank must be emptied. The machine will not pick up water or scrub with the switch activated.

NOTE:

All other indicators vanish and a “Recovery Tank FULL” Indicator

(D7)

turns on in the Display Panel when the switch is activated on “EcoFlex” models. The Hour Meter

(J2)

momentarily

À

ashes each letter of the word FULL over and over on “Standard” models.

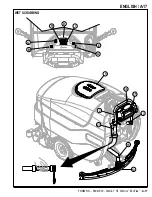

12

When the operator wants to stop scrubbing or the recovery tank is full, press the Scrub OFF Switch

(H)

once. This will automatically stop the scrub brushes and solution

À

ow and

the scrub deck will raise UP.

NOTE:

The vacuum will stop after a 10 second delay. This is to allow any remaining water to be picked up without turning the vacuum back on.

13

Raise the squeegee and drive the machine to a designated wastewater “DISPOSAL SITE” and empty the recovery tank. To empty, pull the Recovery Tank Drain Hose

(27)

from

its hanger and open the cap (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled

À

ow of waste water). The Recovery Tank Drain Hose

(27)

can be squeezed to regulate the

À

ow. Re

¿

ll the solution tank and continue scrubbing.

NOTE:

Make sure the Recovery Tank Cover

(5)

and the Recovery Tank Drain Hose

(27)

cap is properly seated or the machine will not pick-up water correctly.

When the batteries require recharging the Battery LOW Indicator

(D8)

will come on (EcoFlex models) or the Battery Indicator

(J1)

will

À

ash red (Standard models)

and the vacuum motor will shut off after 30 seconds. Transport the machine to a service area and recharge the batteries according to the instructions in the Battery

section of this manual.

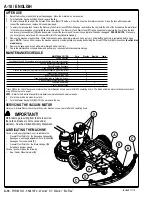

WET VACUUMING

Fit the machine with optional attachments for wet vacuuming.

1

Disconnect the Recovery Hose

(19)

from the Squeegee

(13).

2

Attach suitable wet pick-up tools to the hose (Available from Nil

¿

sk, Inc.).

3

Turn the Master Key Switch

(A)

ON.

4

Press the Wand Switch

(E)

once to turn ON the vacuum motor.

SERVICE NOTE: Refer to the service manual for detailed functional descriptions of all controls and optional programmability.

Содержание 56307250

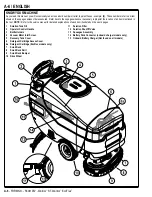

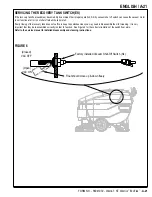

Страница 17: ...ENGLISH A 17 FORM NO 56041972 Warrior ST Warrior EcoFlex A 17 34 35 17 27 19 2 13 A E I D H G 5 B WET SCRUBBING...

Страница 25: ......

Страница 48: ......

Страница 49: ......