MX SERIES AIR HANDLER SAFETY

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only and do

not supersede any national or local codes in any way.

Compliance with all local, state, or national codes pertaining to

this type of equipment should be determined prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

All models are designed for indoor installation only.

The installation of the blower section, field wiring, warm air

ducts, etc. must conform to the requirements of the National

Electrical Code, ANSI/NFPA No. 70 (latest edition) in the United

States, and any state laws, and local ordinances (including

plumbing or wastewater codes). Local authorities having

jurisdiction should be consulted before installation is made.

Such applicable regulations or requirements take precedence

over the general instructions in this manual.

Install the conditioned air plenum, ducts and air filters (not

provided) in accordance with NFPA 90B Standard for the

Installation of Warm Air Heating and Air-Conditioning Systems

(latest edition). The blower section is provided with flanges for

the connection of the plenum and ducts. Air filters must be

listed as Class 2 furnace air filters. The blower section is

shipped from the factory completely assembled.

Do not remove the cabinet knockouts until it has been

determined which knockouts will need to be removed for the

installation.

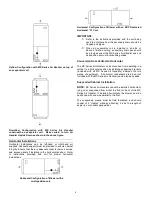

Select the final installation position that best suits the site

conditions. Consider required clearances, space, and routing

requirements for refrigerant line, condensate disposal, filters,

ductwork, wiring, and accessibility for service. Refer to the rating

plate on the blower section for specific information.

This product may contain fiberglass wool insulation.

Glass wool fibers are known to the State of

California to cause cancer. Disturbing insulation

during installation, maintenance, or repair may

expose you to glass wool fibers and may cause

respiratory, skin or eye irritation. For further

information on risks associated with fiberglass wool,

consult Material Safety Data Sheet available at

OEM.

WARNING!

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and

others.

All safety messages will follow the safety alert symbol and

either the word “DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if

you don’t immediately follow

instructions.

You can be killed or seriously injured if

you don’t follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what

can happen if the instructions are not followed.

2