LIST OF ERROR CODES + SOLUTIONS

[in ERROR mode]

If a fault occurs during operation, the system locks out and the screen starts to flash.

The first character is an “E” or “b” and the following two indicate the code of this fault, as indicated in the table below.

To unlock the system:

• Press "RESET" on the screen.

• If the fault is repeated continually, contact your installer.

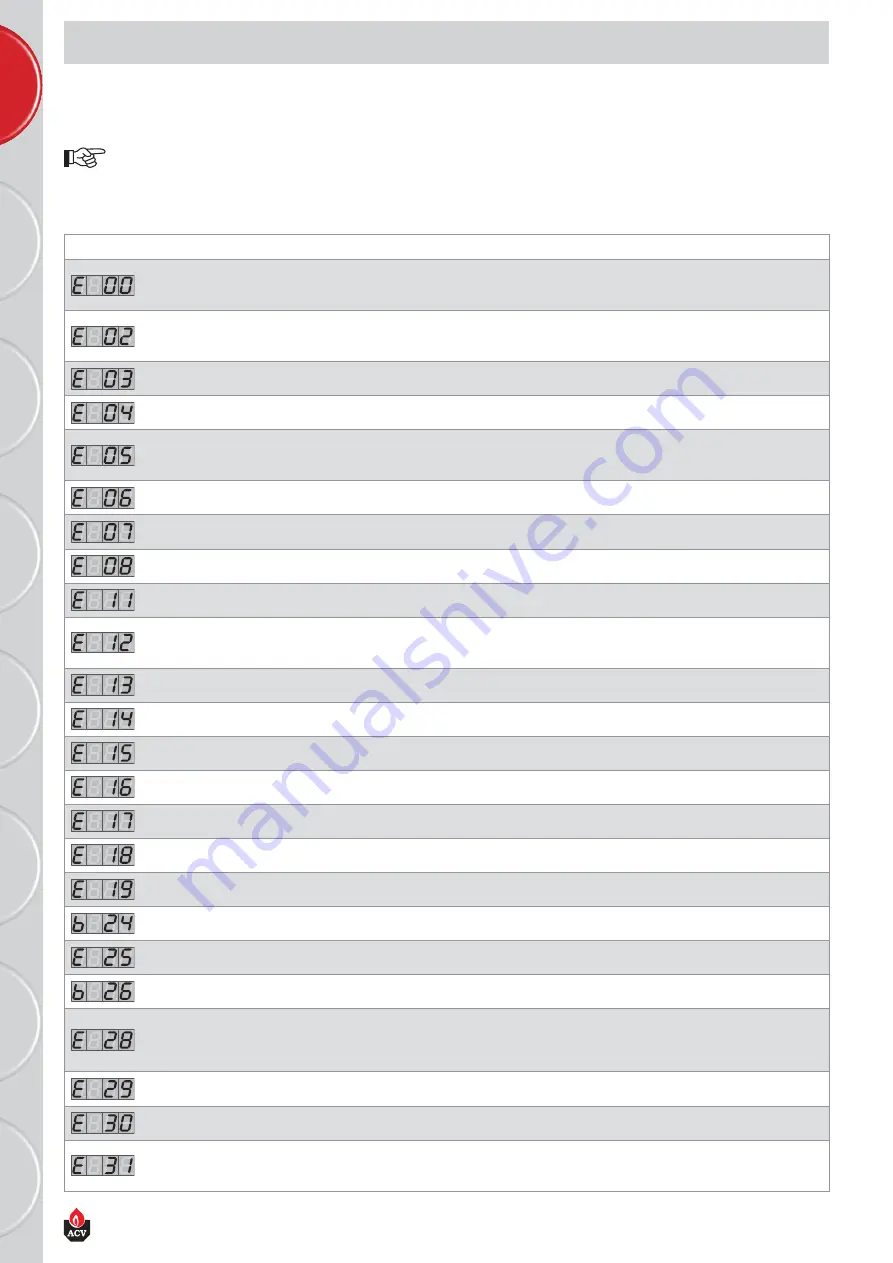

MCBA BLOCKAGE AND ERROR CODES

Codes

Description of the fault

Resolution of the fault

Abnormal flame signal detected

1. Check the wiring (short circuit in the 24 V wiring)

2. Check the electrode

3. Replace the MCBA (water damage)

No flame presence after five start-up attempts

1. Check the ignition wiring

2. Check the electrode and its position

3. Check the burner gas level

Gas valve or triac error

Replace the rectifier or the gas valve

Durable locking

Press “RESET”

No flame detection or poor feed current quality

1. Check the electrode gap

2. Check resistance kΩ of the electrode cable

3. Stabilisation of the current

Detection of an Input error

Check the Input and press “RESET”

Gas valve relay error

If the problem persists after two “RESET” attempts, replace the MCBA

The air pressure switch did not close

Check the air pressure switch

EPROM error

If the problem persists after two “RESET” attempts, replace the MCBA

Max input thermostat open or 24 V fuse has blown.

1. Check the limit thermostat

2. Check the 24 Volt fuse of the MCBA

3. Link 12-13 missing

Internal error

If the problem persists after two “RESET” attempts, replace the MCBA

Water in the 24 Volt circuit

Check the 24 Volt circuit and dry if necessary [sensors, terminal, etc.]

Internal error

If the problem persists after two “RESET” attempts, replace the MCBA

Internal error

If the problem persists after two “RESET” attempts, replace the MCBA

Internal error

If the problem persists after two “RESET” attempts, replace the MCBA

T1 > 110°C

1. Check the NTC wiring and replace it if necessary

2. If the NTC1 sensor is OK, check if there is water flow in the boiler

T2 > 110°C

Check the NTC wiring and replace it if necessary

The NTC1 and NTC2 sensors are the wrong way

round

Switch the NTC1 and NTC2 sensors around

T1 gradient too high

1. Check if the pump is running

2. If there is no problem with the pump, bleed the system

Gas pressure switch or low-water pressure switch

open

Check the gas pressure switch or the low-water pressure switch

No tachometer signal from the fan

1. Check the PWM connection

2. Check the fan’s wiring

3. If the problem persists after two “RESET” attempts, replace the fan. Otherwise

change the MCBA

The fan’s tachometer signal does not drop back

to "0"

1. Check the draught in the flue

2. If the draught is sufficient, replace the fan

Maximum temperature difference between T1 and

T2 is too high

Check the water flow rate

Short circuit NTC1

1. Check the connection of the NTC1 sensor

2. Check the wiring of the NTC1 sensor

3. If the problem persists replace the NTC1 sensor

EN • 28

664Y5300 • A

E

N

FR

R

U

P

L

DE

IT

ES

N

L