Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone:

1-888-967-5224 |

Website:

workaci.com

Page 3

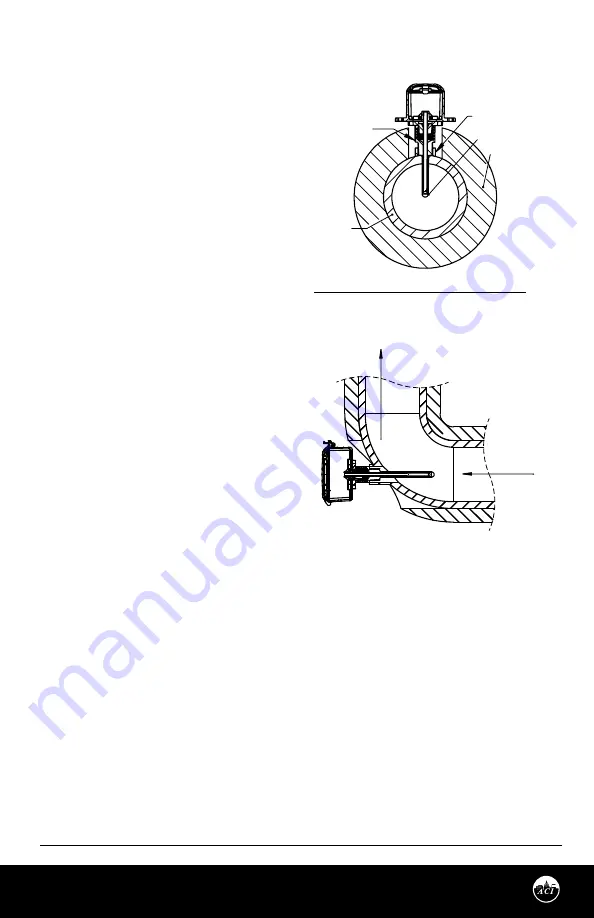

THERMOWELL INSTALLATION

ACI’s standard Immersion sensors are made to

install into a ½” NPT female thread. Typically a

Threadolet or Tee is installed into the pipe, but a

hole can also be drilled and tapped. The

pipe/system will need to be drained, unless a Hot

Tap is being used. The recommend drill size is

23/32 in. (18 mm). Drill the hole, and tap the hole

with ½”-14NPT.

Always use proper thread sealants on tapered

pipe threads of the thermowell. Screw the

thermowell into the Threadolet, Tee, or tapped

hole, using a wrench to tighten it firmly. Refill the

system and check for leaks.

Best practice is to apply thermal grease to the end

of the probe, but not required. Insert and push

the sensor probe into the thermowell. Turn the

sensor probe assembly clockwise to tighten

down completely.

Open the cover of the enclosure. Refer to the

wiring instructions (p. 1) to make necessary

connections. After wiring, attach the cover to the

enclosure.

PROBE INSERTION

The “-INW” includes a standard ½” NPS process

thread to be used with a machined thermowell or

previously installed thermowell. Verify the existing thermowell insertion length of the pipe is suitable for

your selected Immersion.

If the length of the probe is too large, the probe may be pressed into its enclosure - up to an inch of

clearance.

Note:

*Fabricated (welded) thermowells (-I) are not intended for moving water or high pressure service.

Fluid velocity and wake frequency are primary factors in well failure. Machined thermowells (-IM) should be

used in these types of applications. Fabricated thermowells are intended for tank, or low to no flow,

applications.

FLOW DIRECTION

PIPE INSULATION

TIP OF THERMOWELL

IN MIDDLE OF PIPE

THREADOLET

PIPE WALL

THERMOWELL

FIGURE 6:

THREADOLET ASSEMBLY

FIGURE 7:

ELBOW ASSEMBLY

BACnet MS/TP and Modbus RTU INTERFACE

The BACnet Master-Slave/Token-Passing (MS/TP) and Modbus Remote Terminal Unit (RTU) data link

protocol uses EIA-485 as a two-wire, daisy chain network. A branch is a discrete chain of devices connected

to a controller. The max number of devices per segment is 32, as per the BACnet and Modbus

specifications. 4000 ft (1219.2 m) is the maximum recommended length for a segment, which includes all

devices from the controller to the last device in the daisy chain.

BACnet MS/TP and Modbus

RTU INTERFACE

(Continued)

BACnet or Modbus RTU protocol selection is

done via SW4 switch. Place dipswitch #4 to the

OFF position for BACnet and the ON position

for Modbus. Refer to

FIGURE 8

.

ACI’s BACnet sensors are master devices. Only

master nodes are allowed to send and receive

tokens on the MSTP network.

ACI’s Modbus RTU sensors are slave devices.

Only one master is connected to the bus and

several slave nodes are connected to the same

trunk. The Master initiates communication. The

slave nodes only respond to a request from the

Master. Slave nodes do not communicate with

each other.

Each branch must have all devices connected

with (+) connected to (+) and (-) connected to

(-). If a shielded cable is used, this is not to be

connected to the devices. The shield cable

should only be connected on one end to earth

ground, usually at the controller. The start and

end of each branch should have a termination

resistor at the device level or at the controller.

Each device must be configured for the correct

baud rate and have a unique address in each

branch. The baud rate for the branch is set by

the controller. This product has auto-baud for

ease of network configuration but setting the

baud rate using the DIP switches is

recommended.

Note:

Auto-baud feature does

not function when Modbus is the selected

protocol.

Version: 2.0

I0000929