AM1730 Secondary Reference Platinum Resistance Thermometer

User’s Guide

5/10

3 General Operations

3.1 Connecting to the readout device

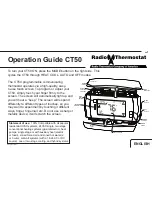

The AM1730 is equipped with a four-wire cable (see Figure 1).

Four lead wires are used to cancel lead wire resistance. For best

results, the readout device should be equipped to handle four-

terminal resistors. The lead wires can be distinguished by

insulation colors. Lead wire pairs attached to each end of the

sensor are identified by red/black and white/blue insulation.

3.2 Drive Current

AccuMac recommends 1mA as drive current to ensure the best

measurement.

3.3 Stability of Readings

To achieve the best accuracy, allow sufficient time for PRT to

stabilize before taking the readings.

3.4 Immersion Requirements

Stem effect can cause measurement errors due to heat lost or

gained by the sensing element through the thermometer stem. To

Figure1

Black

Blue

White

Red