6

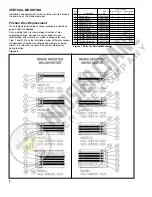

FOR 3-PIECE COUPLED INPUT REDUCERS (Reference Figure 3)

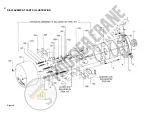

FOR CLAMP COLLAR INPUT REDUCERS (Reference Figure 4)

Prepare the motor by checking the motor shaft extension for dirt or damage. Remove

any anti-rust coating that may be on the shaft. Apply a thin even coating of anti-seize

compound to the entire motor shaft.

Prepare the motor by checking the motor shaft extension for dirt or damage. Use solvent

to remove all traces of anti-rust coating that may be on the shaft.

Insert the coupling key into the motor shaft keyway. Slip the motor coupling half onto the

motor shaft and locate it a distance “ x” from the motor shaft end. Refer to Figure 3 for

definition of distance “ x” . Refer to the table on page 7 for values of “ X” for each motor.

Check the input bore for dirt or damage. Clean the bore with solvent to remove all traces

of oil or anti-rust coating.

Tighten the motor coupling half setscrew to the correct torque value listed below.

For NEMA motors ONLY:

A special long, tall motor key is provided with the QUANTIS

unit.

1. Discard the motor key and replace it with the special key provided.

DO NOT USE

THE MOTOR KEY.

2. If the special key does not fit snugly in the motor shaft keyway, prepare the key

for assembly by nicking its bottom in a couple of spots. A chisel may be used to

accomplish this. This must be done on a work surface away from the QUANTIS unit

and the motor. This nicking should widen the key bottom and cause it to fit snugly in

the motor keyway. Refer to Figure 5 for definition of key bottom.

3. Install the key in the motor shaft keyway by lightly tapping it in place with a rubber

mallet.

4. Locate the key so that it sits flat in the motor shaft keyway. The key will probably

extend beyond the end of the motor shaft. This is OK. The key MUST NOT sit tilted

in the keyway. A tilted key can occur when a motor shaft has a sled runner keyway,

Refer to Figure 5.

5. Mark the clamp collar with a fine tipped marker on both sides of the setscrew to

indicate where the center of the set screw is located. Run a line down both sides of

the clamp collar that line up with the line previously created.

6. Remove the socket head screw and set screw from the clamp collar and apply Loctite

243 thread locker. Reinstall the screws into the clamp collar. Install the clamp collar

onto the reducer input shaft and line up the mark previously made on the clamp

collar with the center of the keyway in the shaft. If the clamp collar rotates freely,

tighten the clamping screw slightly to keep it from rotating during assembly. Make

sure the marked line is pointing to the center of the keyway.

Check that the reducer coupling half, with its key in place, is mounted on the reducer

input shaft inside the C-face adapter. Make sure this coupling half is mounted on the

reducer shaft such that the shaft extends the complete length of the coupling bore.

Insert the coupling spider properly into the coupling jaws.

The DODGE QUANTIS ILH C-Face reducer should be firmly anchored to prevent sliding

as the motor is mounted. The motor should be rotated on its axis so the motor flange

holes line up with the C-Face adapter holes. Check to be sure the motor conduit box,

grease fittings and condensations drains (where fitted) will be oriented as needed by the

reducer mounting position.

The DODGE QUANTIS ILH C-Face reducer should be firmly anchored to prevent sliding as

the motor is mounted. The motor should be rotated on its axis so the motor flange holes

line up with the C-Face adapter holes. Check to be sure the motor conduit box, grease

fittings and condensate drains (where fitted) will be oriented as needed by the reducer

mounting position.

Hoist motor level and in line with reducer input shaft.

Hoist motor level and in line with reducer input shaft.

Align the motor coupling half such that its jaws are aligned with the gaps between the

spider and the reducer coupling half jaws. Push the motor into place. Motor flange to

C-face adapter clearances are tight and good alignment is essential.

Align the motor shaft with the gear reducer input bore making sure that the motor shaft

keyway is in line with the input bore key. Push the motor into place. Motor shaft to input

bore clearances are tight and good alignment is essential.

Insert and tighten the motor retaining bolts Tighten to the correct torque value listed

below.

Insert and tighten the motor retaining bolts. Tighten to the correct torque value listed

below.

FOR 3-PIECE COUPLED INPUT REDUCERS (Reference Figure 3)

FOR CLAMP COLLAR INPUT REDUCERS (Reference Figure 4)

NEMA Motor Frame

Motor Bolt

Bolt Tightening Torque

NEMA Motor Frame

Motor Bolt

Bolt Tightening Torque

56-140

3/8—16

276 lb-in (31 Nm)

56-140

3/8—16

276 lb-in (31 Nm)

180

1/2—13

660 lb-in (75 Nm)

180

1/2—13

660 lb-in (75 Nm)

210

1/2—13

660 lb-in (75 Nm)

210

1/2—13

660 lb-in (75 Nm)

250

1/2—13

660 lb-in (75 Nm)

250

1/2—13

660 lb-in (75 Nm)

280

1/2—13

660 lb-in (75 Nm)

280

1/2—13

660 lb-in (75 Nm)

320

5/8—11

1320 lb-in (150 Nm)

320

5/8—11

1320 lb-in (150 Nm)

360

5/8—11

1320 lb-in (150 Nm)

360

5/8—11

1320 lb-in (150 Nm)

IEC Motor Frame

Motor Bolt

Bolt Tightening Torque

IEC Motor Frame

Motor Bolt

Bolt Tightening Torque

71

M8

220 lb-in (25 Nm)

71

M8

220 lb-In (25 Nm)

80

M10

440 lb-in (50 Nm)

80

M10

440 lb-in (50 Nm)

90

M10

440 lb-in (50 Nm)

90

M10

440 lb-in (50 Nm)

100

M12

800 lb-in (90 Nm)

100

M12

800 lb-in (90 Nm)

112

M12

800 lb-in (90 Nm)

112

M12

800 lb-in (90 Nm)

132

M12

800 lb-in (90 Nm)

132

M12

800 lb-in (90 Nm)

160

M16

1860 lb-in (210 Nm)

160

M16

1860 lb-in (210 Nm)

180

M16

1860 lb-in (210 Nm)

180

M16

1860 lb-in (210 Nm)

200

M16

1860 lb-in (210 Nm)

200

M16

1860 lb-in (210 Nm)

225

M16

1860 lb-in (210 Nm)

250

M16

1860 lb-in (210 Nm)

Table 3 - MOUNTING MOTORS TO C-FACE REDUCERS

Содержание LOUDEN 200 Series

Страница 1: ......

Страница 2: ......

Страница 3: ......

Страница 4: ......

Страница 5: ......

Страница 6: ......

Страница 7: ......

Страница 8: ......

Страница 9: ...FIGURE 8 FIGURE 9 FIGURE 10 FIGURE 11...

Страница 10: ......

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 14: ......

Страница 15: ......

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 29: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ......

Страница 49: ......

Страница 50: ......

Страница 51: ......

Страница 52: ......

Страница 53: ......

Страница 54: ......

Страница 55: ......

Страница 56: ......

Страница 57: ......

Страница 58: ......

Страница 59: ......

Страница 60: ......

Страница 61: ......

Страница 62: ......

Страница 63: ......

Страница 64: ......

Страница 65: ......

Страница 66: ......

Страница 67: ......

Страница 68: ......

Страница 69: ......

Страница 70: ......

Страница 71: ......

Страница 72: ......

Страница 73: ......

Страница 74: ......

Страница 75: ......

Страница 76: ......

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ......

Страница 101: ......

Страница 102: ......

Страница 103: ......

Страница 104: ......

Страница 105: ......

Страница 106: ......

Страница 107: ......

Страница 108: ......