Cutter Balance: "Dialing in" your cutter

Raster™ Braille cutters are precision-

machined to very close tolerances and are

tested for accuracy before leaving the factory.

But sometimes a little fine-tuning is needed to

make a cutter work as it should.

Balance is very important to a cutter's

performance. If the balance is off, a cutter

can drill holes that are much too large. You

can change the balance of a cutter by

changing its orientation in the spindle.

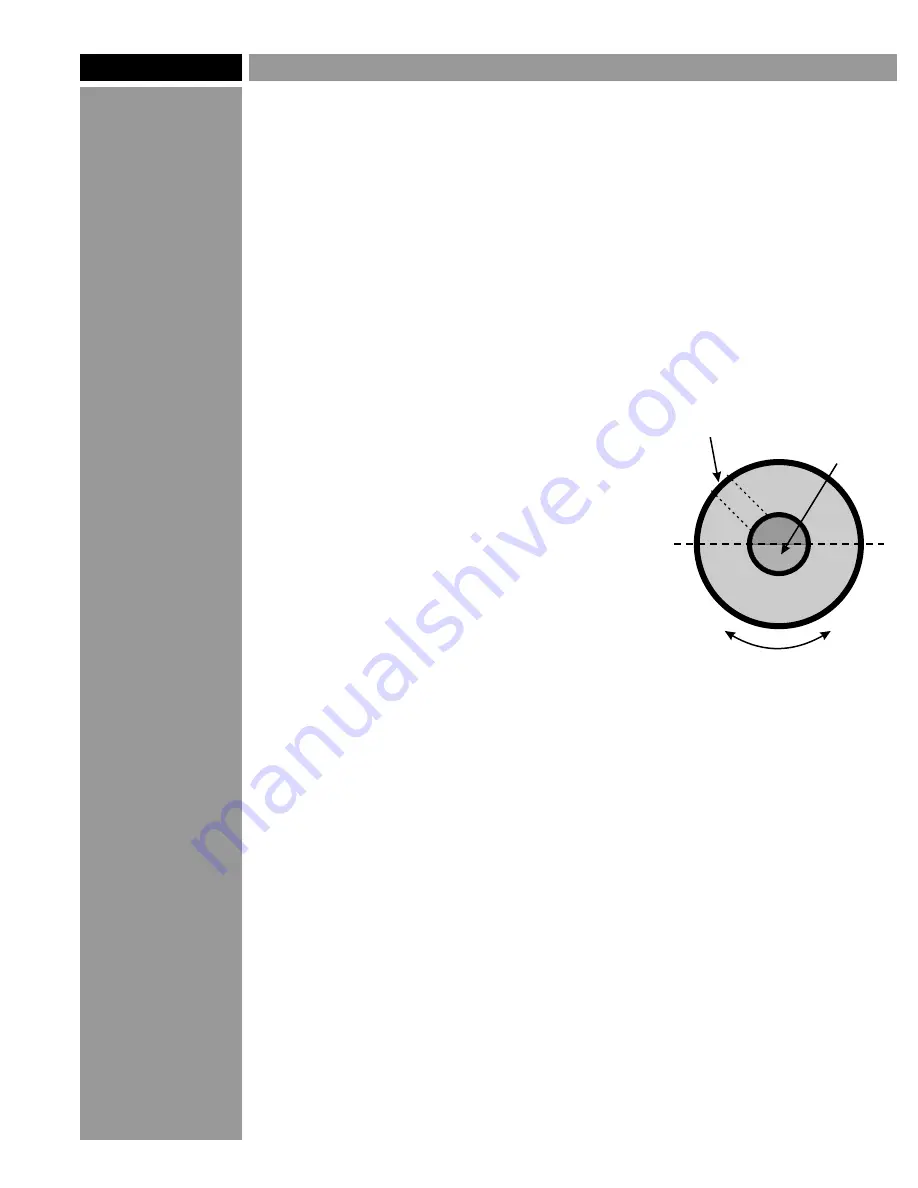

Loosen the setscrew and turn the cutter 180

degrees, then retighten the screw. This will

change the orientation of the cutter's "flat"

side in relation to the brass knob and the

spindle itself. Now try drilling again and check

the holes. If it still isn't right, rotate it 90

degrees and try again.

Be careful not to lose track of your "0" point

on the micrometer during this procedure.

There is no one correct position

, so try a

few different positions until the cutter drills

the proper size holes. You can tell by the

sound it makes: as the cutter gets closer to

being in balance, it runs quieter.

You can also try adjusting the spindle speed,

on materials where the speed isn't critical

(most engraving plastics fall into this

category). A particular cutter may run

smoother and work better at a lower or higher

speed than normal.

Page 7

©2005 Accent Signage Systems, Inc. All rights reserved.

TM

Raster Method of Braille

"flat" side

of cutter tip

Location of

setscrew

Top View

of Cutter

Rotate the cutter

within the knob

to change the

orientation

Brass

knob