2

ALL THE INSTALLATION, PuTTING INTO

SERVICE, RuNNING AND MAINTENANCE

OPERATIONS MuST bE CARRIED OuT by

SkILLED PERSONNEL wITH IN-DEPTH

kNOwLEDGE OF THE APPARATuS.

CAUTION

1.Foreword

1.1. Introdution

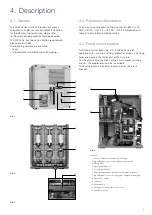

This publication contains the information needed to install

medium voltage Vmax/w and Vmax circuit-breakers and put

them into service.

For correct use of the product, please read it carefully.

Like all the apparatus we manufacture, the Vmax/w and

Vmax circuit-breakers are designed for different installation

configurations.

However, they do allow further technical and construction

modifications (at the customer’s request) to adapt to special

installation requirements.

For this reason, the information given below may sometimes

not contain instructions concerning special configurations.

Apart from this manual, it is therefore always necessary to

consult the latest technical documentation (circuit and wiring

diagrams, assembly and installation drawings, any protection

coordination studies, etc.), especially regarding any variants

requested in relation to the standardised configurations.

For example, the racking and interlock sections do not apply

to the fixed mount breaker styles. All information in this

booklet was current at the time of printing. unless otherwise

noted, all references in this booklet are determined by viewing

the circuit-breaker from the front.

Only use original spare parts for maintenance operations.

For further information, please also see the technical

catalogue of the circuit-breaker.

1.2. Environmental protection

programme

The Vmax/w and Vmax circuit-breakers are manufactured

in accordance with the ISO 14000 Standards (Guidelines for

environmental management).

The production processes are carried out in compliance

with the Standards for environmental protection in terms of

reduction in energy consumption as well as in raw materials

and production of waste materials. All this is thanks to

the medium voltage apparatus manufacturing facility

environmental management system.

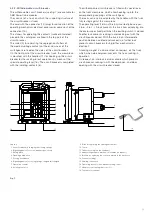

1.3. Vacuum interrupter quenching

principle

Due to the extremely low static interrupter chamber pressure

of 10-4 to 10-8 mbar, only a relatively small contact gap is

required to achieve a high dielectric strength. The vacuum

arc is extinguished on one of the first natural current zeros.

Due to the small contact gap, high conductivity of the metal

vapour plasma, and short arcing time, the associated arc

energy is extremely low, which has advantageous effects

on the life of the contacts and thus on that of the vacuum

interrupters.