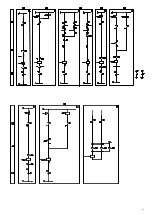

32

20 Nm

20 Nm

fig. 26

Checking screw tightening

5.2.4. inspections and functional tests

interruption devices in general

– Carry out regular inspections to check that the interruption

devices are in good condition.

– Inspection at fixed intervals can be waived when the

apparatus is permanently monitored by qualified personnel.

– Above all, the checks must include a visual inspection

to check for any contamination, traces of corrosion and

electrical discharge phenomena.

– Carry out more frequent inspections when there are unusual

operating conditions (including adverse climatic conditions)

and in the case of environmental pollution (e.g. heavy

contamination or an atmosphere with aggressive agents).

– Visual examination of the isolating contacts.

Turning the system of contacts alternately is recommended,

in order to keep the internal surface of the contact areas

clean. The contact areas must be cleaned if there are signs

of overheating (discoloured surface) (also see the paragraph

on “Repairs”).

– If any anomalous conditions are found, appropriate

servicing measures must be taken (see the paragraph on

“Servicing).

functional test

– Make the circuit-breaker safe by discharging the closing

springs (close and open the circuitbreaker by means of the

closing and opening pushbuttons).

– with the circuit-breaker in the test position, carry out a

few opening and closing operations by means of the shunt

opening and closing releases.

– The nuts and screws are tightened in the factory and

correct tightening is marked with a coloured sign. Further

tightening operations during the operating life of the circuit-

breaker are not foreseen. However, if it should be necessary

to tighten the nuts or screws again following any trips, the

values indicated in fig. 26 must be respected.

Stored energy operating mechanism Carry out the functional

test of the operating mechanism every 5,000 operations or

every 4 years. before doing the test, open the circuit-breaker

and carry out the following operations:

– for withdrawable circuit-breakers, take the circuit-breaker to

the test position

– for fixed circuit-breakers: cut off the voltage to the medium

voltage circuit.

note

Insulate the working area and make it safe, following the

safety regulations specified in the ANSI C37.04 – C37.54 –

C37.09 – C37.55 VDE Standards.