14

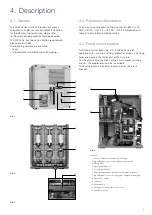

4.5. Preliminary operations

Clean the insulating parts with clean dry cloths.

Check that the top and bottom terminals are clean and free of

any deformation caused by shocks received during transport

or storage.

4.5.1. installation of fixed circuit-breakers

Vmax circuit-breaker can be fixed directly on the supporting

plate or on a truck provided by the customer. The customer

must guarantee a minimum degree of protection (IP2X) from

the front towards live parts.The fixed version of Vmax circuit-

breaker must be installed by the customer so as to guarantee

a minimum degree of protection as for C37.20.2 and C37.55

test requirements.

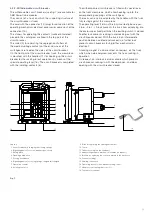

4.5.2. insertion and removal withdrawable circuit-breaker

This section describes the process for inserting the breaker

into the disconnect position of the switchgear and the

removal of the circuit-breaker from the disconnect position.

Racking of the circuit-breaker to and from the test and

disconnect position is covered in the following section.

insertion

(Refer to Fig. 7 and 13)

(From withdrawn Position to Disconnect Position)

1. Align breaker and ramp, dolly or lift truck with circuit-

breaker compartment

2. Pull handles (17) to center (this withdraws Cell Interlock

Tabs (11) allowing breaker to be inserted)

3. Push breaker into breaker compartment with handles.

4. Align Cell Interlock Tabs with Circuit breaker Compartment

Slots (A)

5. Push Handles out to fully engage Cell Interlock Tabs into

Circuit breaker Compartment Slots

6. Visually check that Cell Interlock Tabs are engaged in

Circuit-breaker Compartment Slots (if Cell Interlock Tabs

are not fully extended, racking is prevented) breaker is now

in the Disconnect Position

Removal

(Refer to Fig. 7 and 14)

(From Disconnect Position to withdrawn Position)

1. Visually check to see the Truck (11) is against the Locator

Channel

2. Pull Handles to center (this withdraws Cell Interlock Tabs;

allowing breaker to be removed .

4. Pull the breaker from Circuit-breaker Compartment with the

Handles onto the required transportation device.

4.5.3. withdrawable circuit-breakers with truck

made by third parties

The Vmax circuit-breakers installed on trucks made by the

customer must be fitted with one or two additional auxiliary

contacts (operated by the mechanical lock and by the circuit-

breaker release device) which are entrusted with the function

of interrupting the shunt closing release circuit (-MC).

In this way it is certain that no electrical impulse can activate

the shunt closing release with the circuit-breaker in an

intermediate position.

The customer must also provide a lock to prevent circuit-

breaker traverse when it is in the closed position.

4.5.4. installation of withdrawable circuit-breakers

in abb PowerCube modules

The withdrawable circuit-breakers are use in PowerCube

modules see Fig. 13 - 14.

For racking-in/racking-out of the switchgear: connect the

secondary plug (14) (fig. 7) with secondary disconnector

(b) (fig.14) , fully insert the crank handle (1) (fig. 11 in the

appropriate seat) (2) (fig.11) and work it clockwise for racking-

in, and anti-clockwise for racking-out, until the end-of-run

positions are reached.

Circuit-breaker racking- in/-out must be carried out gradually

to avoid shocks which may deform the mechanical interlocks

and the end-of-runs.

The torque normally required to carry out racking- in and

racking-out is <25 Nm.

This value must not be exceeded. If operations are prevented

or difficult, do not force them and check that the operating

sequence is correct.

note

To complete the racking-in/out operation, 20 turns of the

crank handle are required.

when the circuit-breaker has reached the connect/

disconnect position it can be considered as racked into the

switchgear and, at the same time, earthed by means of the

truck wheels.

THE RACkING-IN/-OuT OPERATIONS

MuST ALwAyS bE CARRIED OuT wITH

THE CIRCuIT-bREAkER OPEN.