Installation

16

RHD250 ... 4000 42/68-165-EN

Pos: 8.22 /Montage/Aktorik/Elektr. Schwenkantriebe/RHD250...4000/Montage mit Hebeltrieb @ 14\mod_1194260399171_3101.doc @ 135753

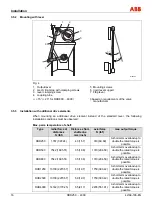

3.5.2 Mounting

with

lever

b

a

1

2

3

5

4

6

7

3°

10°

M00303

Fig. 4

1

Output lever

2

mech. limit stop with clamping screws

3

lever clamping screw

4

coupling tube

α

≥

15° (

≥

20° for RHD800 ... 4000)

5

Mounting screws

6

rigid, level support

7

Flap lever

β

based on requirements of the valve

manufacturer

Pos: 8.23 /Montage/Aktorik/Elektr. Schwenkantriebe/RHD250...4000/Montage mit anderen Abtriebselementen @ 14\mod_1194272226406_3101.doc @ 136108

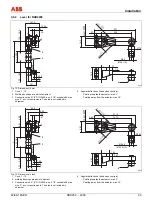

3.5.3 Installation with additional drive elements

When mounting an additional drive element instead of the standard lever, the following

installation conditions must be observed:

Max. perm. temperature of shaft:

Type

radial force at

distance x

N (lbf)

Distance x from

shaft edge

mm (inch)

axial force

N (lbf)

max. output torque

RHD250 1767

(397.24)

40 (1.57)

310 (69.69)

A short-term overload up to

double the rated torque is

possible

RHD500 7542

(1695.51) 35

(1.38) 1310 (294.50)

A short-term overload up to

double the rated torque is

possible

RHD800 7542

(1695.51) 35

(1.38) 1310 (294.50)

A short-term overload up to

double the rated torque is

possible

RHD1250 10100

(2270.57)

50

(1.97) 1750 (393.42)

A short-term overload up to

double the rated torque is

possible

RHD2500 10100

(2270.57)

50

(1.97) 1750 (393.42)

A short-term overload up to

double the rated torque is

possible

RHD4000 14142

(3179.25)

55

(2.17) 2455 (551.91)

A short-term overload up to

double the rated torque is

possible

Pos: 8.24 /Montage/Aktorik/Elektr. Schwenkantriebe/RHD250...4000/Gestaltung der Antriebselementnabe @ 14\mod_1194420363093_3101.doc @ 136723