57

1 / 1

1:2

A3

Sheet No.

Format

Language

Scale

Subtitle

Type

Derived from

Name

Date

Location

Revision

Drawn

Checked

Approved

EC No.

EN

Drawing status

Title

Drawing No.

Responsible

ABB Switzerland Ltd

Weight

Material

f

m

c

v

H

L

K

PROPRIETARY AND SECRET INFORMATION The information contained in this document has to be kept stric

tly confidential.

Any unauthorized use, reproduction, distribution or disclosure

to third parties

is strictly forbidden. ABB reserves all rights regarding Intell

ectual Property Rights.

Thread Quality Tolerance

"6g-6H" ISO 965

ISO 2768 T.1 Lengths and Angle

ISO 2768 T.2 Geometrical Tolerances

Surface

Surface code

Coord. punching N.C.Mach.

and unfold JS11

Standard Tolerances for Machining and Forming

© Copyright

ABB. All rights reserved.

2016

5

4

3

2

1

H

G

F

D

C

B

A

H

G

F

E

C

B

A

5

4

3

2

1

Group Technology Management

M. Mańkowski

PL-PSY

05.03.2020

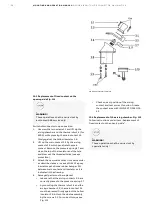

20.1 Hollow insulators with arcing chamber. Fig.

113

1. Unscrew 3.9 and detach the insulator.

2. Attach the new insulator to the frame by the

two self-tapping screws in case of DMC

(BMC) insulators or standard metric screws

in case of epoxy insulators. Remember to

mount the piston with piston rod 3.10. For

correct torque see Fig. 114.Note the washer

and spring washer for the screws.

20.2 Insulator for fuse-base and quick make

earthing switch

1. Unscrew 4.2 and detach the fuse clips and

contact block respectively.

2. Unscrew 4.3 at the base of the insulator and

detach the insulator.

3. Attach the new insulator to the frame by the

two self-tapping screws in case of DMC

(BMC) insulators or standard metric screws

in case of epoxy insulators 4.3. For correct

torque see Fig. 115. Note the washer and

spring washer for the screws.

4. Attach the fuse clips and contact block

respectively to the top of the insulator by the

screws 4.2. For correct torque see Fig. 115

—

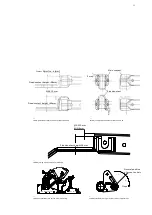

113 Tightening torque for screws NAL/VR 12/17,5/24

—

114 Tightening torque for screws NAL/VR 12/17,5/24

D

D

2019-08-27

1 / 1

C. Nożyński

PL-PSY

PLABB

1:2

A2

A. Sypniewski

P. Spalitabaka

2019-08-27

PL-PSY

PL-PSY

2019-08-27

NAL

Post insulator with contact knife

complete NAL 17,5/24kV 630A

Sheet No.

Format

Language

Scale

Subtitle

Type

Derived from

Name

Date

Location

Revision

Drawn

Checked

Approved

EC No.

EN

Marketing documentation

Drawing status

Title

Drawing No.

Responsible

1YMX000271M0136

ABB Switzerland Ltd

Weight

Material

f

m

c

v

H

L

K

X

X

PROPRIETARY AND SECRET INFORMATION

The information contained in this document has to be kept strictly confidential.

Any unauthorized use, reproduction, distribution or disclosure to third parties

is strictly forbidden. ABB reserves all rights regarding Intellectual Property Rights.

Thread Quality Tolerance

"6g-6H" ISO 965

ISO 2768 T.1 Lengths and Angle

ISO 2768 T.2 Geometrical Tolerances

Surface

Surface code

Coord. punching N.C.Mach.

and unfold JS11

Standard Tolerances for Machining and Forming

© Copyright

ABB. All rights reserved.

2016

11

10

9

H

G

8

7

6

5

4

3

2

1

11

10

9

8

7

1

2

3

4

5

F

D

C

B

A

E

H

G

F

E

A

B

C

D

6

Group Technology Management

1 / 1

1:3

A3

Sheet No.

Format

Language

Scale

Subtitle

Type

Derived from

Name

Date

Location

Revision

Drawn

Checked

Approved

EC No.

EN

Drawing status

Title

Drawing No.

Responsible

ABB Switzerland Ltd

Weight

Material

f

m

c

v

H

L

K

PROPRIETARY AND SECRET INFORMATION The information contained in this document has to be kept stric

tly confidential.

Any unauthorized use, reproduction, distribution or disclosure

to third parties

is strictly forbidden. ABB reserves all rights regarding Intell

ectual Property Rights.

Thread Quality Tolerance

"6g-6H" ISO 965

ISO 2768 T.1 Lengths and Angle

ISO 2768 T.2 Geometrical Tolerances

Surface

Surface code

Coord. punching N.C.Mach.

and unfold JS11

Standard Tolerances for Machining and Forming

© Copyright

ABB. All rights reserved.

2016

D

C

8

A

B

E

8

7

6

5

4

3

2

1

A

B

C

D

E

7

6

5

4

3

2

1

Group Technology Management

PL-PSY

M. Mańkowski

PLABB

—

20.0 Replacement of insulators

—

115 Support insulators

_

WARNING!

These operations shall be carried out by

authorised ABB service only!

_

WARNING!

These operations shall be carried out by

authorised ABB service only!

40 [Nm]

+

/

-

10%

15 Nm

15 Nm

15 Nm

4.2

4.1

4.3

15 [Nm]

(standard DMC

and epoxy insulators)

15 [Nm]

(DMC insulators

with inserts)

15 Nm

15 Nm