—

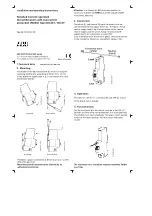

Figure 15: Allen Screw to be loosened for Stop Block Removal

—

Figure 16: Screwdriver Placement for Deflection of Assembly Wall

—

Figure 17: Removal of Stop Block Assembly

—

F

igure 18: Stop block in position in breaker.

Replace the Electric Operator if previously rem oved

by securing with the long screws on the left side of

the spring assembly wall and the short hex screws on

the bottom of the spring assembly (Figure 23).

Operate the charging handle one more time to fully

charge the spring, then close and trip the breaker.

Operate the charging handle once and hold the

handle extended while reinstalling the breaker top

cover, as shown in Figure 2. Tighten the four #10-32

screws to 15 in-lb.

Replace the trim plate, if present, and tighten the four

#8-32 mounting screws to 20 in-lb.

Operate the charging handle until the spring is

completely charged. Close and trip the breaker.

Return the breaker to operation.

Tubing

with

Collar

Spring Frame

Bearing

5

21.

22.

23.

24.

25.

26.