Aztec 600 ISE ammonia and fluoride

Single-stream ion-selective analyzers

Appendix C – Principle of Operation – Ammonia Analyzers

OI/AXM630–EN Rev. I

81

Appendix C – Principle of Operation – Ammonia Analyzers

C.1 General Operation

The analyzer uses an ammonia probe. The probe contains a

glass pH electrode (whose pH-sensitive glass membrane forms

a slightly convex tip) and a robust, long-life reference electrode.

The two electrodes are combined into a single assembly and are

connected as a pH measuring pair through an internal reservoir

of filling solution. The filling solution is 0.1 M ammonium chloride

saturated with silver chloride and is separated from the sample

by a gas-permeable hydrophobic membrane fitted to the tip of

the probe.

As sample flows past the probe membrane, the partial

pressures of the ammonia gas in the sample on one side of the

membrane and the filling solution on the other equalize,

transferring gas across the membrane. At equal pressure, the

concentration of ammonia in the thin film of filling solution

between the probe membrane and the pH-sensitive glass

electrode membrane equals that in the sample. The resultant

change in the pH value of the thin film is measured by the pH

electrode pair, creating an output potential related to the

ammonia concentration in the sample. Like most ion-selective

electrodes, the ammonia probe produces an output that is

logarithmic in respect to concentration.

The analyzer's sequence of operation is as follows:

1. Sample is supplied to a side sample pot constant head

unit by a sample pump. Excess sample overflows to drain.

2. From the constant head unit, the sample is drawn through

the normally open ports of solenoid valves SV1 and SV2

by one channel of a peristaltic pump.

3. Reagent is drawn through another channel of the

peristaltic pump and mixed with the sample.

4. The conditioned sample is pumped into a flowcell

containing the ammonia probe. The probe is enclosed in a

heated block housing a heat-exchanger, ensuring that the

body of the probe remains at a constant temperature and

also at a temperature in agreement with that of the sample

and standard solutions.

5. When exposed to the reacted sample, the probe

produces an electrical potential that changes in proportion

to the changes in activity of the measured ion.

6. The probe is connected to the electronics section where,

after digital conversion, the signal is processed by

microprocessor.

7. After measurement, the sample flows to waste via a

contaminated drain connection.

During calibration, Low and High standard solutions are

introduced sequentially in place of the sample by means of

solenoid valves SV1 and SV2. The resultant millivolt Low and

millivolt High readings from the probe are stored as the

calibrated readings. The analyzer can be configured to perform

automatic calibrations from every 6 hours to once per week. A

calibration can also be initiated manually if required.

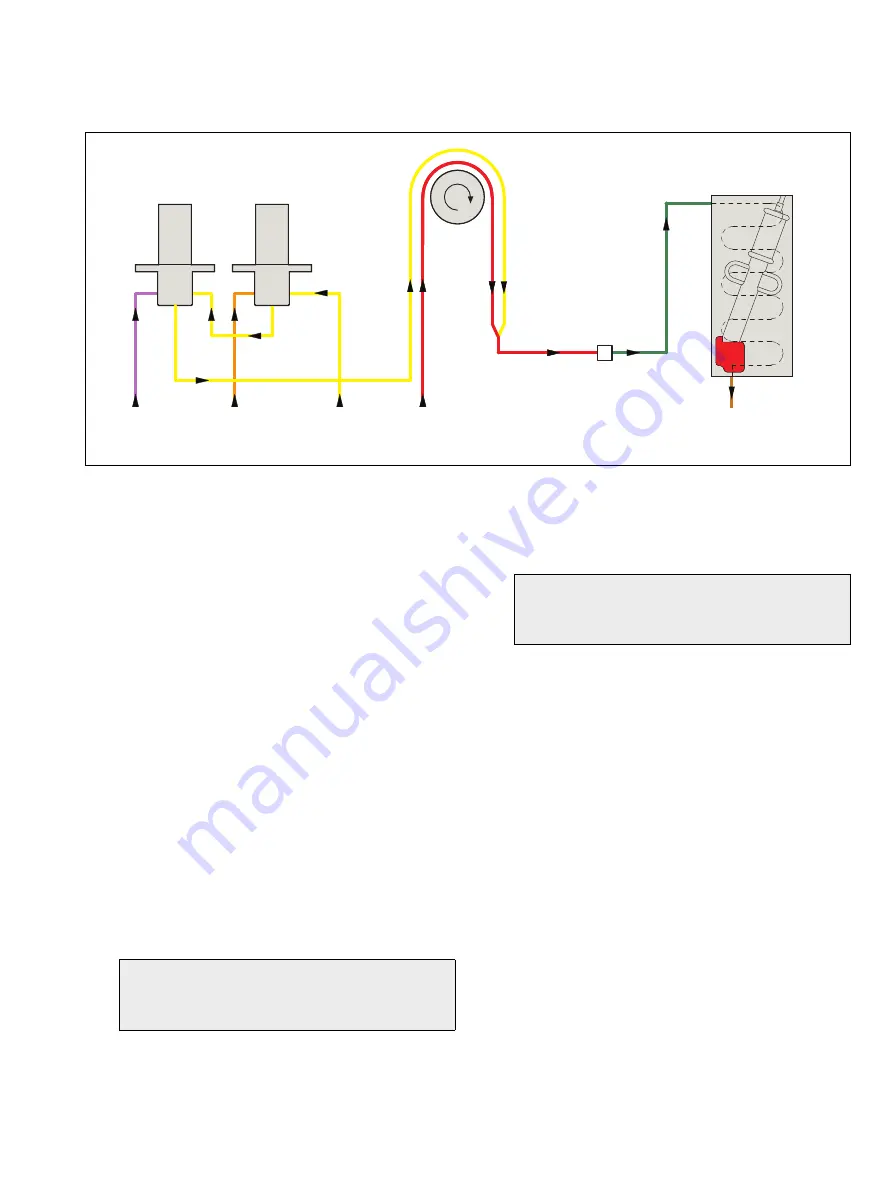

Fig. C.1 Flow Schematic

Waste

Standard

solution (low)

Standard

solution (high)

Reagent

Sample from

side sample pot

Reagent

pump

Ammonia flowcell

assembly (red)

Solenoid valve and manifold assemblies

C

o

nd

iti

o

ned samp

le

Note.

The constant head unit is fitted with a float

switch that signals an 'Out-of-sample' condition by

triggering an 'Out-of-Sample' alarm.

Note.

The sample and reagent tube diameters are

sized to obtain the correct ratio of sample and

reagent.