AOS WPC - Tech Training

45 of 72

Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

VF BOILER SERVICE MANUAL

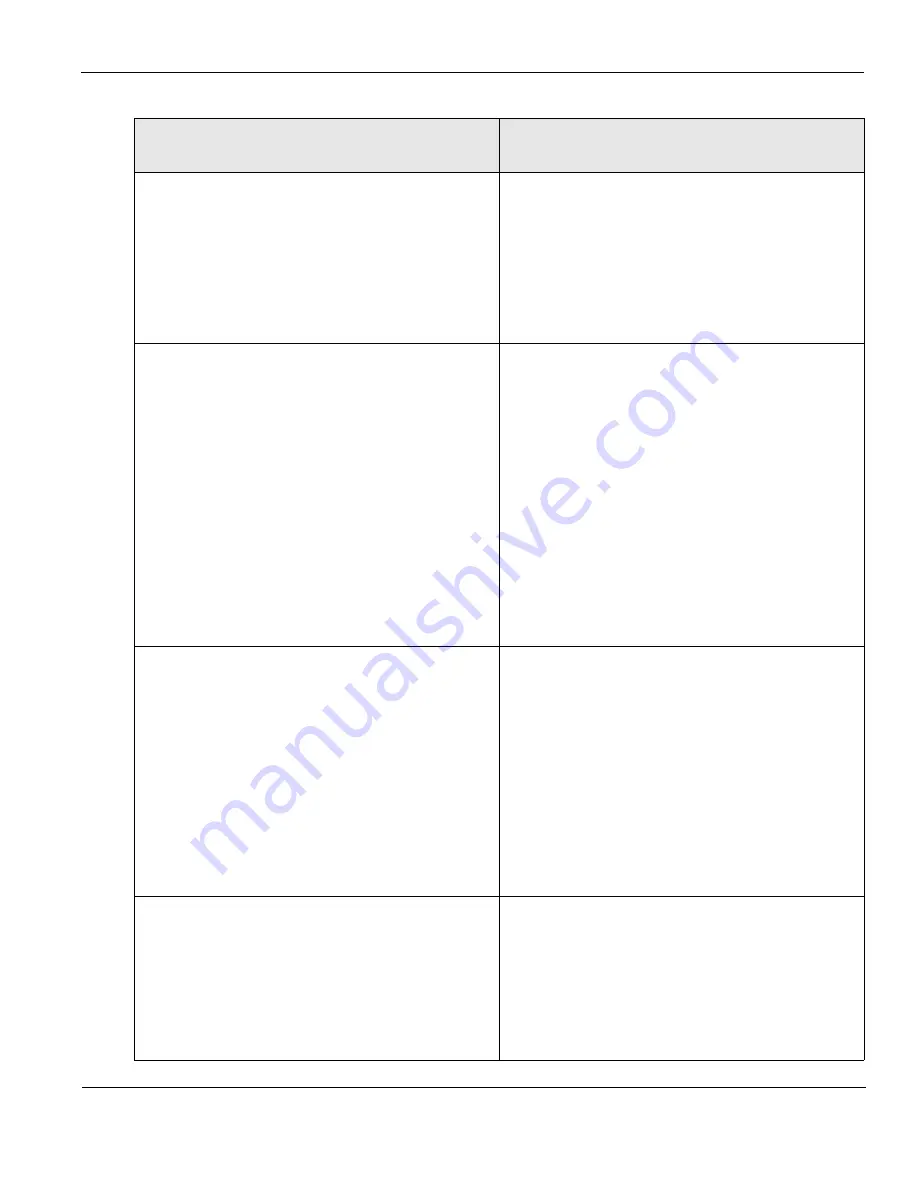

ERROR MESSAGES (CONT)

DISPLAYED MESSAGE

CONDITION/INDICATES

CHECK/REPAIR

“Low AC Voltage”

Power supply polarity is reversed. Line voltage to

boiler is less than 90 VAC.

•

Ensure power supply polarity is not reversed

and boiler is properly grounded.

•

Perform Power Supply Test Procedure (page

40) - correct any problems indicated by test.

•

Check incoming power supply, wiring, and all

line voltage connections on the boiler and at the

breaker or disconnect switch - repair/restore

115 - 120 VAC power supply to boiler.

“Low 24 VAC”

Voltage from transformer is less than 18 VAC.

Important Service Reminder:

When performing any troubleshooting steps outlined

in this service manual always consider the wiring

and connectors between components. Perform a

close visual inspection of all wiring and connectors

to a given component before replacement.

Failure to perform this critical step or failing to

perform this step thoroughly often results in

needless down time, unnecessary parts

replacement, and customer dissatisfaction.

•

Check 120 VAC to transformer. Check for 115 -

120 VAC between pins 3 & 6 of the J1 socket on

the PDB (page 38). Perform this test with the

wiring harness plugged into the J1 Socket.

•

Ensure transformer is 100 VA rated - replace

transformer if rating is less than 100 VA.

•

Secure power to boiler; temporarily disconnect

load wiring from secondary coil on transformer.

Turn power back on and check voltage at sec-

ondary coil - if secondary (24 VAC) voltage

remains low - replace transformer.

•

Check all 24 VAC wiring for worn/damaged con-

nections or wires - replace/repair as necessary.

•

Replace transformer.

“Low Water”

Water is not being sensed by optional LWCO (low

water cutoff) device’s sensor.

•

Ensure there is water in the lines/boiler.

•

Remove and clean LWCO sensor.

•

If the SW1 #6 dip switch is configured for LWCO

present when the optional control is not installed

on the boiler. This will return a “Low Water” error

message. Check “Config Settings” menu screen

(see page 9) to confirm correct LWCO dip

switch setting. Set SW1 #6 dip switch on the

MCB correctly (see page 30).

•

Check all wiring, plugs, and sockets (J4 socket

on the MCB board - see page 28) for good con-

nections - repair/replace damaged/worn parts.

“Low Gas”

Supply gas pressure has dropped below pressure

activation point of the Low Gas Pressure switch.

Low gas pressure switch is standard on VF boilers.

SW1 dip switch #7 is set to “on” to configure the

control system to monitor this switch (page 30).

•

Check supply gas pressure with boiler firing at

100%. Ensure supply pressure is maintained

above 4.0" W.C. for natural gas and 6.4" W.C.

for propane - replace low gas switch if supply

pressures are maintained above activation point

at 100% firing rate and error message persists.

•

Ensure gas line is properly sized. - adjust gas

supply pressure at regulator serving the boiler.