LUBRICATION INFORMATION

All moving parts in the winch are permanently lubricated with high temperature lithium grease at the time of assembly.

Under normal conditions factory lubrication will suffice. If the rope cable becomes worn or damaged it must be replaced.

ROPE INSTALLATION

It is recommended that if the synthetic rope needs to be replaced you engage a qualified technician to perform this task.

AUXILIARY ITEMS (not included)

As a further safeguard, you may wish to consider installing the following items:

• An additional isolation switch on the positive lead from your battery to avoid the possibility of malicious use by an

ill intentioned person.

• A second battery to avoid depleting the power of the battery that starts your vehicle, as the use of any winch

draws a considerable amount of power.

1. a)

The winch is to be mounted into a suitable steel mounting frame using the 4 point foot mounting system in either

a horizontal or vertical plane.

b)

It's very important that the winch be mounted on a flat surface so that the three sections (motor, cable drum and

gear housing) are properly aligned.

c)

Before commencing installation ensure the mounting facility being used is capable of withstanding the winch’s

rated capacity.

d)

The fitment of winches and / or a frontal protection system may affect the triggering of SRS air bags. Check that

the mounting system has been tested and approved for winch fitment in the airbag equipped vehicle.

2.

Should you wish to manufacture your own mounting plate, the dimensions below will assist. A steel mount plate

6mm thick is recommended. Fasteners should be steel high tensile grade 5 or better. A poorly designed mount

may void warranty.

3.

The winch should be secured to the mounting with 3/8"UNCx1-1/4" bolts and spring washers provided.

4.

The roller fairlead is to be mounted so as to guide the rope onto the drum evenly.

Installation

MOUNTING YOUR WINCH

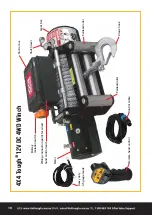

21-280467 12V DC 4WD Winch - Dimensions

(Dimensions are in millimetres)

Front view

Top view

16

5

64

21

8

TO

-C

LE

A

R

548

170

254

224

11

4

124

16

0

device correctly will void any warranty. The manufacturer will not be held responsible for damage

caused to property or persons as a result of inadequate installation.

ELECTRICAL CONNECTION

For normal self-recovery work, your existing electrical system is adequate. A fully charged battery and proper

connections are essential. Run the vehicle engine during winching operations to keep battery charged.

.

Pay close attention to proper electrical cable connection as follows (refer to diagrams below):

1.

Short red cable (A) with red jacket connecting to the red terminal (A) of the motor.

2.

Short black cable with yellow jacket (B) connecting to the yellow terminal (B) of the motor.

3.

Short black cable with blue jacket (C) connecting to the blue terminal (C) of the motor.

4.

Thin black cable (Earth) connecting to bottom Earth Terminal of the motor.

5.

Long black cable (1.8m

)

one terminal connecting to the bottom Earth Terminal of the motor, and the

other terminal connecting to negative (-) terminal of the battery.

6.

Long red cable positive

7.

It is essential that the cables are correctly connected by an experienced person who understands the wiring

connection procedure. Incorrect wiring may cause the solenoid unit to cease operating.

In such cases new solenoid replacements are available for purchase.

(+) connecting to positive (+) terminal of the battery.

11