This manual is the property of

. No part of it may be reproduced in any form.

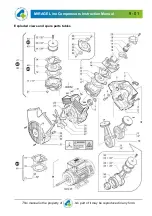

MIRAGE Line Compressors Instruction Manual

6 - 04

Major servicing

The check must carried out periodically, at a frequency that

depends on the dental surgery's workload.

For a dental surgery working eight hours/day fi ve days/week if

the compressor is monitored also by the dental surgery routine maintenance person, it is

suffi cient to arrange a service visit once every six or twelve months.

The major servicing: technician must use exclusively genuine original parts and must not

alter the compressors or their operation or tamper with the safety systems.

Do not weld the compressor air receiver.

Before starting work, read the Instruction Manual and any other relevant documentation

(exploded views, parts lists, wiring diagrams) in the reserved area of our website

www.4-tek.it.

Before carrying out maintenance work on the compressor, disconnect the electrical supply.

Make sure that the compressor reaches the maximum control pressure after each fi lling

cycle and check that the fi lling times are as shown in the table on page 5-03.

Check electrical power consumption in accordance with the values shown on the product

label.

When the compressor starts with diffi culty, check the mains voltage and the capacitance of

the capacitor (check the rating data).

A change in running noise or excessive vibration of the compressor can be a sign of a fault

and the risk of breakdown.

Check that the plant room temperature is no higher than 40°C: compressor operation may

be impaired in higher ambient temperatures.

Check to ensure there is no water in the receiver.

Check to ensure routine maintenance operations are performed correctly; if they are not,

inform the equipment owner of the importance of maintenance to keep the compressor in

good working order.

Change the air-intake fi lters at least once a year (Fig. 1).

2

1