(

Westinghouse

LL. 41 -1 37.3D

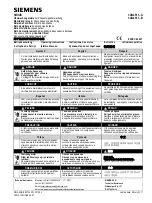

INSTALLATION

•

OPERATION

•

MAINTENANCE

INSTRUCTIONS

TYPE KRD-4 DIRECTIONAL OVERCURRENT

GROUND RELAY

CAUTION:

Before putting relays into service, re

move all blocking which may have been inserted for

the purpose of securing the parts during shipment,

make sure that all moving parts operate freely, in

spect the contacts to see that they are clean and

clo se properly , and operate the relay to check the

settings and electrical conne ctio ns.

A P P L I C A T I O N

The

KRD- 4

relay is a high speed directional over

current relay which is used for the protection of trans

mission lines and feeder transmission lines and feeder

circuits. These relays are dual polarized relays which

can be polarized from a potential source , from a local

ground source, or from both simultaneously.

They are also used, without modifications to pro

vide directional ground fault protection in the

KD-4

carrier relaying scheme. Op eration of the relays in

connection with the carrier scheme is fully described

in

I . L . 4 1-9 1 1.

C O N S T R U C T I O N

The typ e

KRD- 4

directional overcurrent ground

relay consists of a dual polarized directional unit,

an instantaneous overcurrent unit, and an indicating

contactor switch. The principal parts of the relay and

their location are shown in Fig.

1

to

3.

A. DI RECTIONAL UNI T (D)

The directional unit of the

KRD- 4

consists of an

inductio n cylinder unit, phase shifting network , and

a de-coupling network .

l, I nduction Cyl i nder Unit

The cylinder unit is a product type in which tor

que is produced by the phase relationship of an oper

ating flux and a polarizing flux on an aluminum cylin

der supporting a moving contact arm . A contact op en

ing torque or a co ntact clo sing torque is produced

depending upon the phase relationship between the

two fluxes.

SUPERSEDES I . L. 41 - l 37.3C

*Den otes chan ge from superseded issue .

The cylinder unit consists of three basic ass em

blies: an electroma gnet assembly, a moving elem ent

assembly, and a stationary closing assembly.

The electromagnet assembly consists of an elec

tromagnet , an adjustable magnetic core, two magnetic

adjusting plugs, lower bearing pin , and a die-casted

aluminum frame . The moving element ass embly con

sists of a spiral spring, contact carrying member, and

an aluminum cylinder which is assembled to a molded

hub which holds the s haft. The shaft ha s removable

top and bottom j ewel bearings. The stationary con

tact assembly consists of a molded bridge , upper

bearing pin, stationary contact housing and spring

adjuster is located on the underside of the bridge

and is held in place by a spring type clamp. It is

attached to the moving contact arm by a spual spring.

The electromagnet has four poles, two operating

poles and two polarizing poles. Each pair of pol es

are diametrically opposite each other and are excited

by series connected coils. (Two sets of series con

nected coils are used to excite the polarizing poles,

one set for current polarizing and the other set for

voltage polarizing). The electromagnet is permanently

mounted to the frame in such a manner that an air

gap exists between the pole faces of the electromagnet

and the magnetic core. The aluminum cylinder of the

m oving

element assembly rotates in

this air

gap on

the upper and lower pin bearing.

With the contacts closed, the el ectrical connec

tion is made through the stationary contact housing

clamp, then the moving contact, through the spiral

spring out to the spring adjusted clamp.

2.

Phase Shi fting Network

The phase shifting network consists of a resistor,

capacitor and reactor in the polarizing circuit of the

directional unit, and a saturable shunt in the oper

ating circuit.

3. De-Coupl ing Network

The de-coupling .network consists of an air gap

EF FECTIVE J U N E 1 971

www

. ElectricalPartManuals

. com

Summary of Contents for KRD-4

Page 27: ...w w w E l e c t r i c a l P a r t M a n u a l s c o m ...

Page 108: ... w w w E l e c t r i c a l P a r t M a n u a l s c o m ...

Page 110: ...w w w E l e c t r i c a l P a r t M a n u a l s c o m ...

Page 112: ...w w w E l e c t r i c a l P a r t M a n u a l s c o m ...

Page 114: ...w w w E l e c t r i c a l P a r t M a n u a l s c o m ...