IL-2000SA

SERVICE MANUAL

First Edition, November 2007

Manual No. RS-61021-11

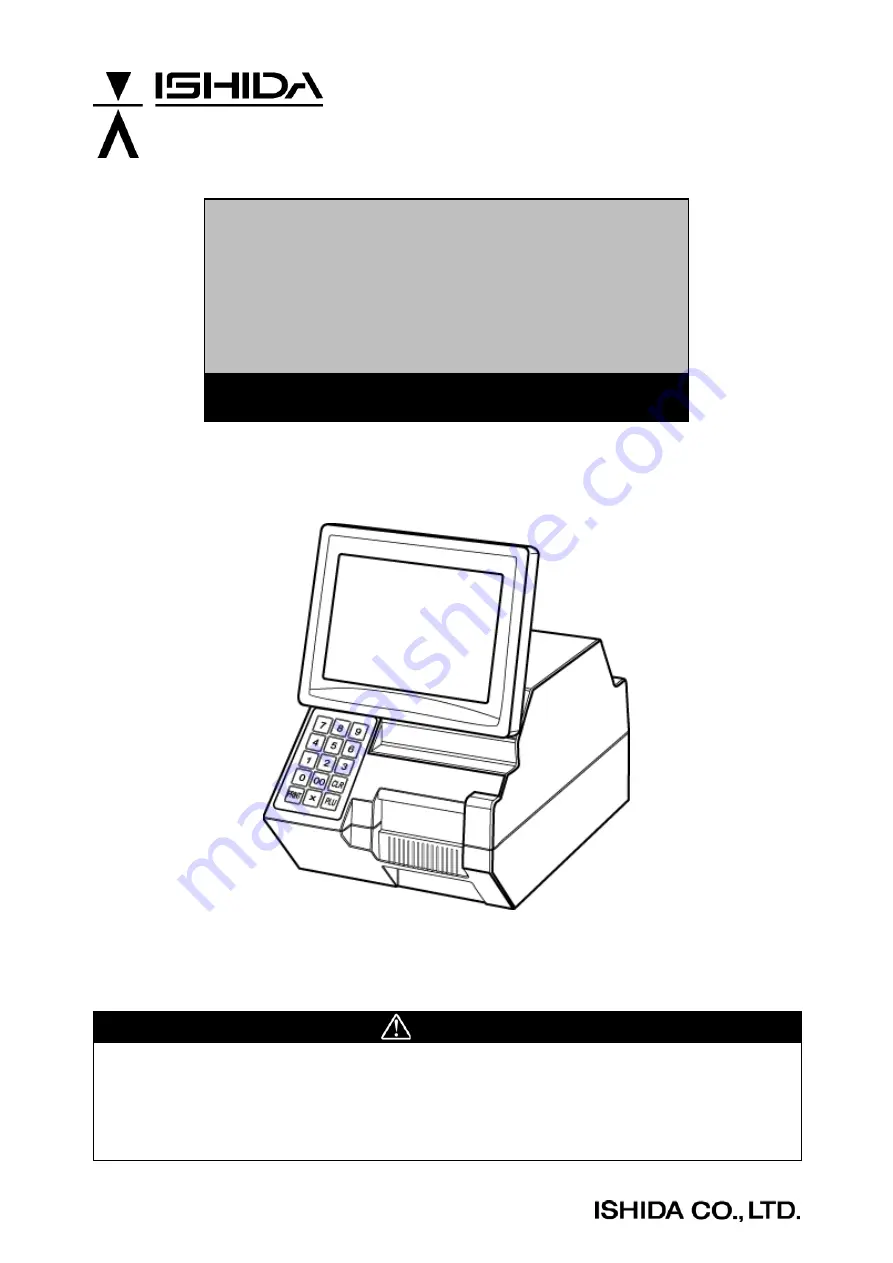

CAUTION

READ AND UNDERSTAND THIS MANUAL

•

Thoroughly read and understand this manual before installing, operating, inspecting, or

servicing the machine.

•

Keep this manual in a safe place where you can refer to it whenever necessary.

DISCONTINUED

107743

Summary of Contents for IL-2000SA

Page 10: ...D I S C O N T I N U E D ...

Page 32: ...D I S C O N T I N U E D ...

Page 76: ...D I S C O N T I N U E D ...