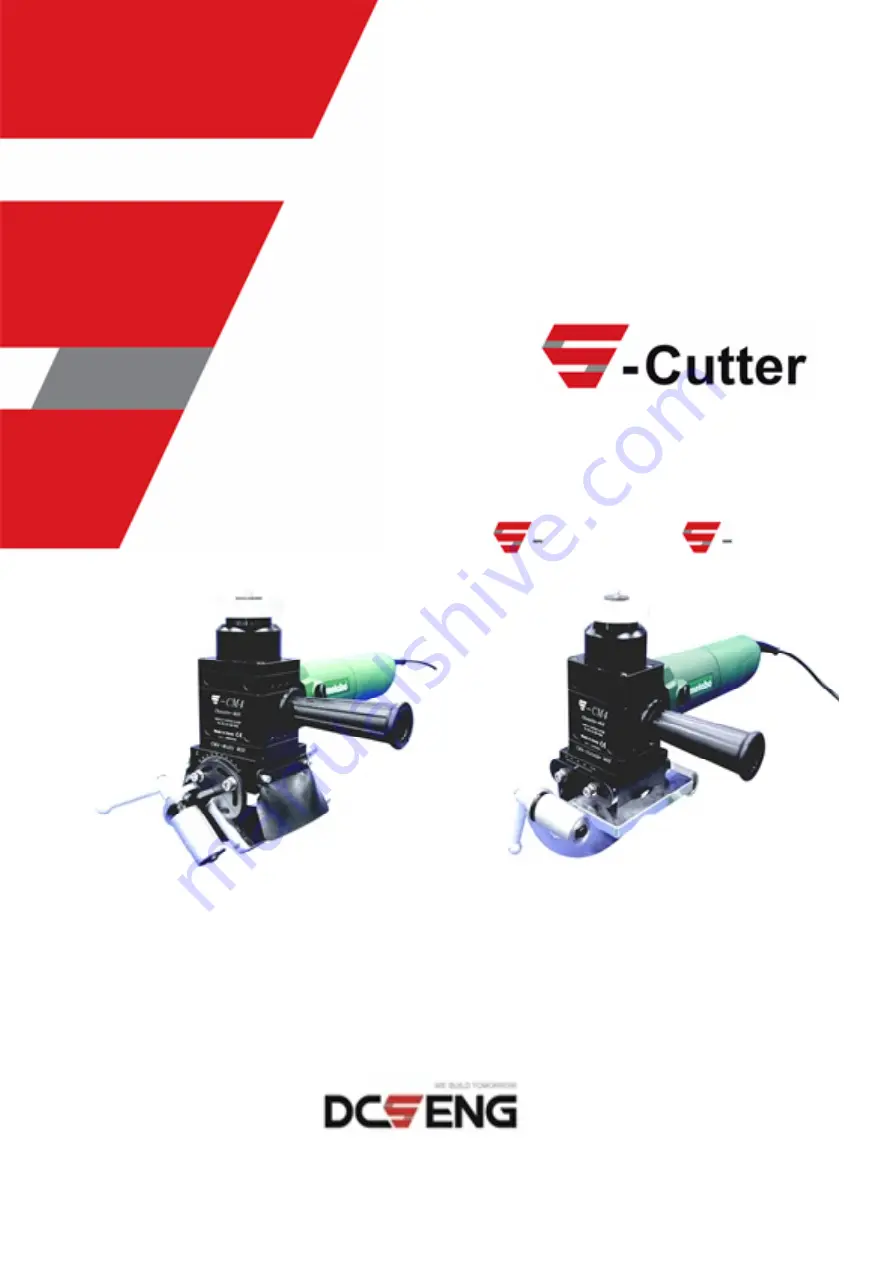

PIPE(TUBE) CUTTER Of Best Technology

Manual

( ( CM4_M / CM4_OD)

SAFETY PRECAUTIONS

Thanks for choosing the S-Cutter.

Make sure that you carefully read and fully understand the Manual to use the device correctly

and keep yourself and your properties safe.