13

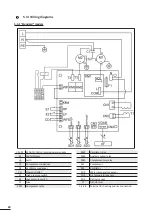

3.3 I Operating

•

Check that there are no tools or other foreign objects in the machine.

•

The panel that provides access to the technical section must be put in place.

•

Set the valves as follows: valve B wide open, valves A, C, D and E closed

: water entry valve

: by-pass valve

: water exit valve

: water entry adjustment valve (optional)

: water exit adjustment valve (optional)

•

An incorrect by-pass setting may cause the heat pump to malfunction.

•

Check that the hydraulic corrections are correctly tightened and that there are no leaks.

•

Check that the device is fully stable.

•

Set the water circulation running.

•

Close valve B gradually so that the filter pressure is increased by 150g (0.150 bars).

•

Open valves A, C and D fully then valve E by half (the air which has built up in the heat pump condenser and the

filtration circuit will bleed out). If valves D and E are not present, open valve A wide and close valve C by half.

•

Connect the power supply to the heat pump:

program version number (different according to model)

Screen saver

Press and hold for 2 seconds

Splash screen

Temperature setpoint

•

Device starts after a timer of up to 5 minutes,

•

Set the temperature you want ("setpoint" temperature) by pressing

or

.

•

After the steps to start up your heat pump, stop the water circulation temporarily to check that your device stops after

a few seconds (by activating the flow controller):

the water flow light must flash.

Information: light water flow

EN