OPERATION

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

40

ZI-RWM84

18.4.1

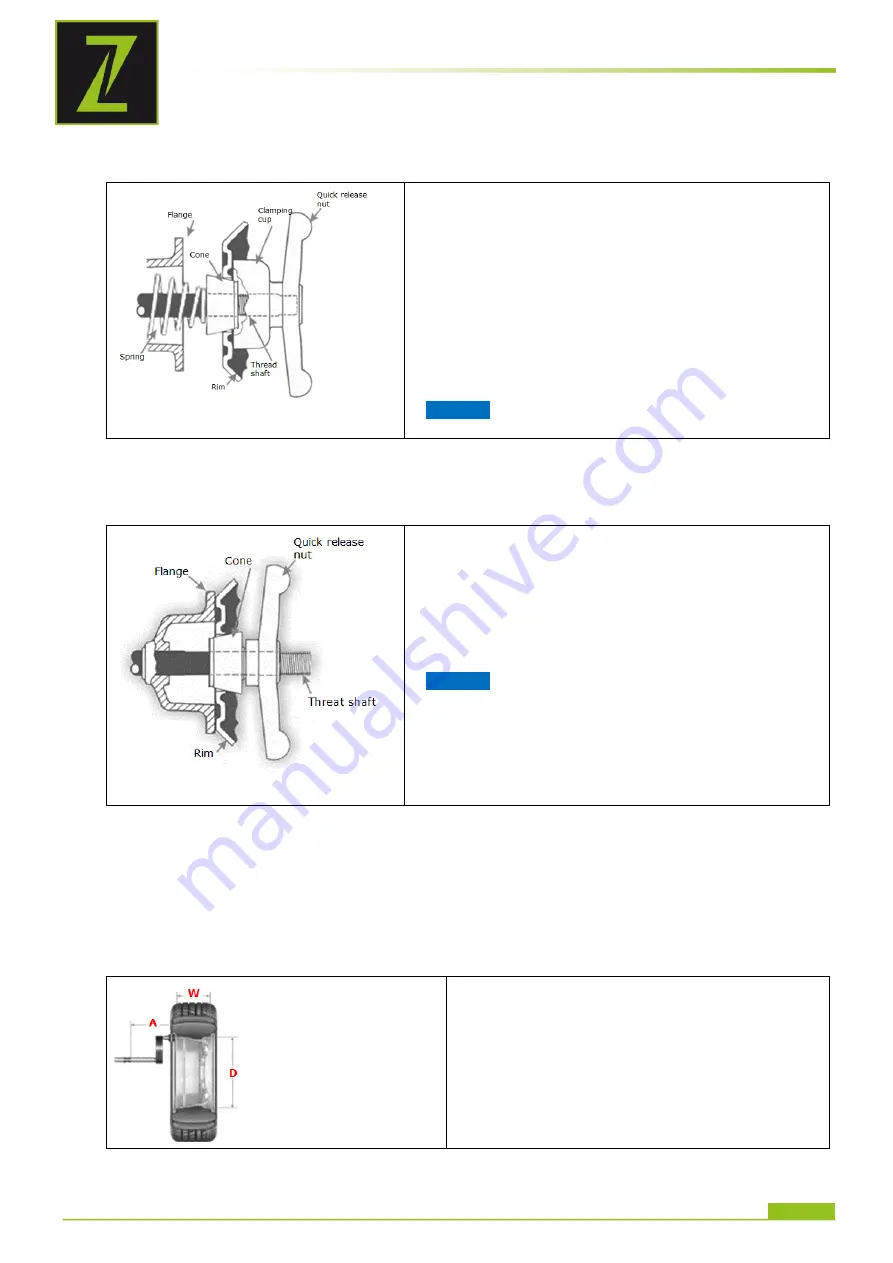

Back centering-cone mounting

The majority of steel rims can be mounted using this method.

Make sure that the clamping cup is attached to the

quick release nut.

Select the appropriate cone for the size of the tyre

centre hole and slide it with the larger diameter

towards the flange on the threaded shaft.

Slide the tyre onto the threaded shaft. Make sure

that the inside of the rim is in contact with the

flange and the cone.

Slide and lock the quick-release nut with clamping

cup on the threaded shaft. The quick-release nut

should be engaged in the thread by at least three

full turns.

NOTICE:

To protect the rim, use a nylon spacer

between the rim and the clamping cup.

18.4.2

Mounting the cone outside

A tyre should only be fixed using this method if the inside of the rim does not provide a precise

centering fit.

Make sure that the clamping cup is NOT attached to

the quick release nut.

Slide the tyre onto the threaded shaft. Make sure

that the inside of the rim is in contact with the

flange and the cone.

Select the appropriate cone for the tyre centre hole

and slide it onto the threaded shaft with the smaller

diameter towards the flange.

NOTICE:

It is necessary to lift the tyre to insert the

cone into the tyre centre hole to avoid damaging

the thread shaft.

Slide and lock the quick-release nut WITHOUT

clamping cup on the threaded shaft. The quick-

release nut should be engaged in the thread for at

least three full turns.

18.5

Setting the rim dimensions

Before a wheel can be balanced, the dimensions A, D and W must be entered. There are two ways

of entering the wheel data:

manual entry

automatic entry

Definition of dimensions A, D and W

A:

Distance value: The distance is measured

from the machine to the inner plane of the

rim (INNER weight location).

D:

Nominal diameter D: Extends between the

rim shoulders and is indicated in inches.

W:

Nominal size W: The width of the rim at the

rim flange.