Page 16 Function-Decoders MX681, MX685, MX686, MX687, MX688

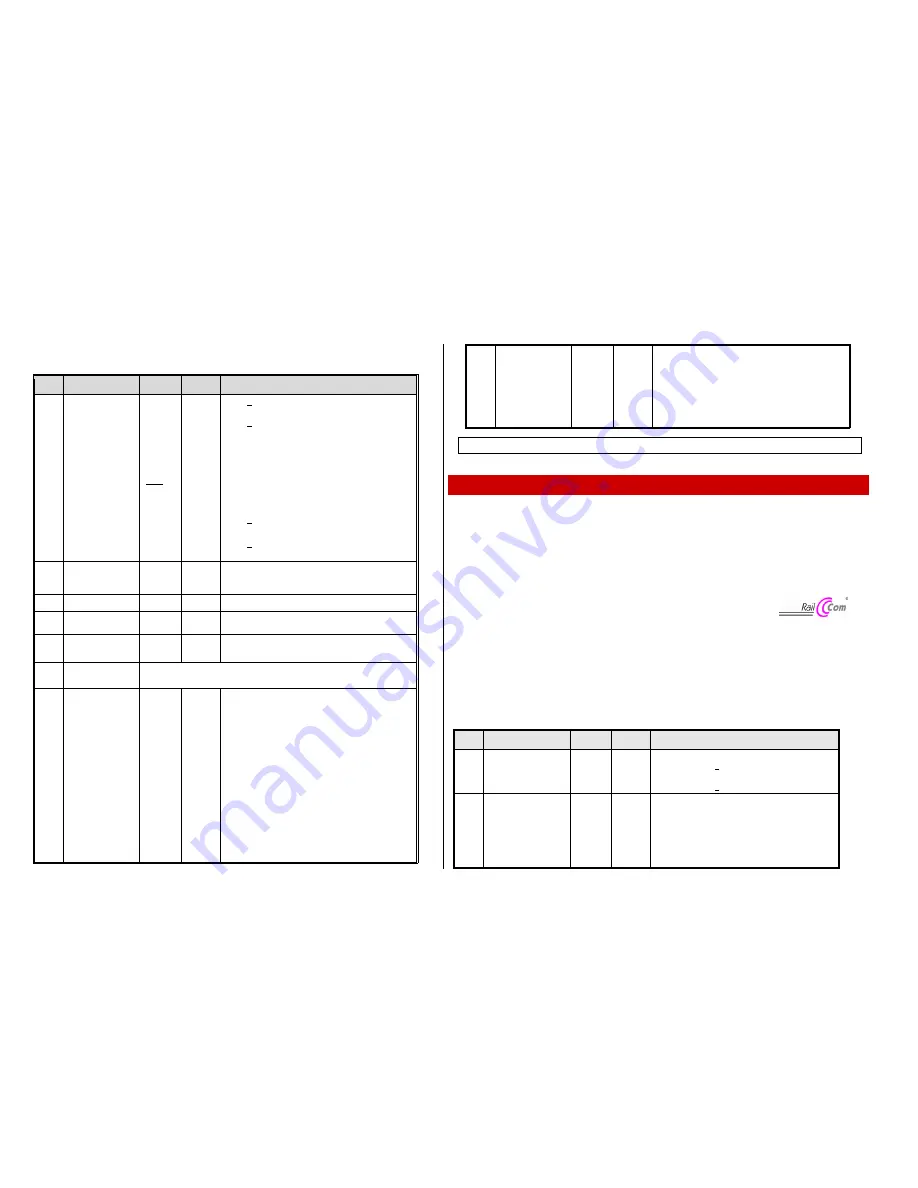

3.17 Servo Configuration

CV

Denomination

Range

Default

Description

#161

Servo outputs:

Protocol

0 - 3

0

Note:

CV #161

must be

set to “2”

for

Smart

Servo

RC-1!

0

Bit 0 = 0: Servo protocol with positive pulses.

= 1: Servo protocol with negative pulses.

Bit 1 = 0: Control wire only active during movement

= 1: … always active (consumes power, vibrates

at times but holds position even under

mechanical load)

– this setting is also required

for

SmartServo RC-1

(with memory wire)!

Bit 2 = 0: Moves to center position, if defined for two-key

operation (see CV #181/182), when both

function keys are OFF.

= 1: Servo runs only if function keys are pressed

when in two-key operating mode

(see CV #181/182).

Bit 6 = 0: Servo1 for first address

= 1: Servo1 for secondary address

Bit 7 = 0: Servo2 for first address

= 1: Servo2 for secondary address

#162

Servo 1 - Left stop

0 - 255

49

= 1 ms

pulse

Servo’s left stop position. “Left” may become the right

stop, depending on values used.

#163

Servo 1 - Right stop

0 - 255

205

Defines the servo’s right stop position.

#164

Servo 1 - Center

position

0 - 255

127

Defines a center position, if three positions are used.

#165

Servo 1 - Rotating

speed

0 - 255

30

= 3 sec

Rotating speed; Time between defined end stops in

tenths of a second (total range of 25 sec, default 3 sec.).

#166

- 169

As above but for

Servo 2

#181

#182

Servo 1

Servo 2

Function

assignment

0 - 28

90 - 93

101-114

0

0

= 0: Servo not in operation

= 1: Single-key operation with F1

= 2: Single-key operation with F2

and so on to

= 28: Single-key operation with F28

= 90: Servo action depends on loco direction:

forward = turns left; reverse = turns right

= 91: Servo action depends on loco stop and direction:

turns right when stopped and direction is forward, oth-

erwise turns left.

= 92: Servo action depends on loco stop and direction:

turns right when stopped and direction is reverse, oth-

erwise turns left.

= 93: Servo action depends on loco movement: turns

right when loco stopped, left when loco moving; direc-

tion makes no difference.

= 101: Two-key operation F1 + F2

= 102: Two-key operation F2 + F3

and so on

= 111: Two-key operation F11 + F12

= 112: Two-key operation F3 + F6

= 113: Two-key operation F4 + F7

= 114: Two-key operation F5 + F8

(Two-key mode operates as defined with

CV #161, Bit 2)

Connecting servos to decoder:

consult the

loco decoder loco manual

!

4

Feedback -

“Bidirectional communication”

All ZIMO decoder types have been equipped with a type of feedback ever since DCC was formed,

which has always been a major difference to competitor products:

- the

ZIMO loco number identification

is part of ZIMO DCC decoders since 1997 and as

far back as 1990 with ZIMO’s own data format (which is no longer in use today). It can only be used

with ZIMO DCC systems (MX1…MX10, MX31ZL, MX32ZL…) and together with ZIMO track section

modules (MX9, StEin and successors): The decoder sends acknowledgment pulses after receiving

DCC packets, which are utilized to identify and locate the decoder in the respective track section.

- the

“bidirectional communication”

according to

“RailCom”

is ready

in all ZIMO decoders since 2004; in the later decoders such as the MX630,

MX640 etc., it is operational since the beginning (basic functions and coming

extensions).

“Bidirectional” means that the information transfer within the DCC protocol is not only flowing towards the decoder

but also in the opposite direction; that is not just driving, function and switch commands are being sent to decod-

ers but also messages such as acknowledgements, actual speed, other status information and CV read-outs are

being received from decoders.

The functioning principle of RailCom is based on the introduction of short cut-outs (max. 500 micro seconds) to

the otherwise continuously sent DCC signal by the command station. These cut-outs provide the time and oppor-

tunity for the decoders to send a few bytes of data to locally mounted detectors.

The RailCom relevant CVs are:

CV

Designation

Range

Default Description

#28

Bi-Directional

Communication

Configuration

0 - 3

3

Bit 0 - RailCom Channel 1 (Broadcast)

0 = OFF

1 = ON

Bit 1 - RailCom Channel 2 (Data)

0 = OFF

1 = ON

#29

Configuration Data #1

0 - 63

14 =

0000

1

110

Which is

Bit 3 = 1

(“RailCom“

activated)

Bit 0 - Train direction:

0 = normal, 1 = reversed

Bit 1 - Number of speed steps:

0 = 14, 1 = 28

Bit 2 - DC operation (analog):

0 = off 1 = on

Bit 3 -

RailCom (“bidirectional communication“)

0 = deactivated

1 = activated