INSTALLATION AND OPERATING INSTRUCTIONS:

Tool changer, pneumatic, WWR1000 series

Zimmer GmbH

●

Im Salmenkopf 5

●

77866 Rheinau, Germany

●

Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80

●

www.zimmer-group.de

7

DDOC00291 / 0

EN / 2018-09-1

1

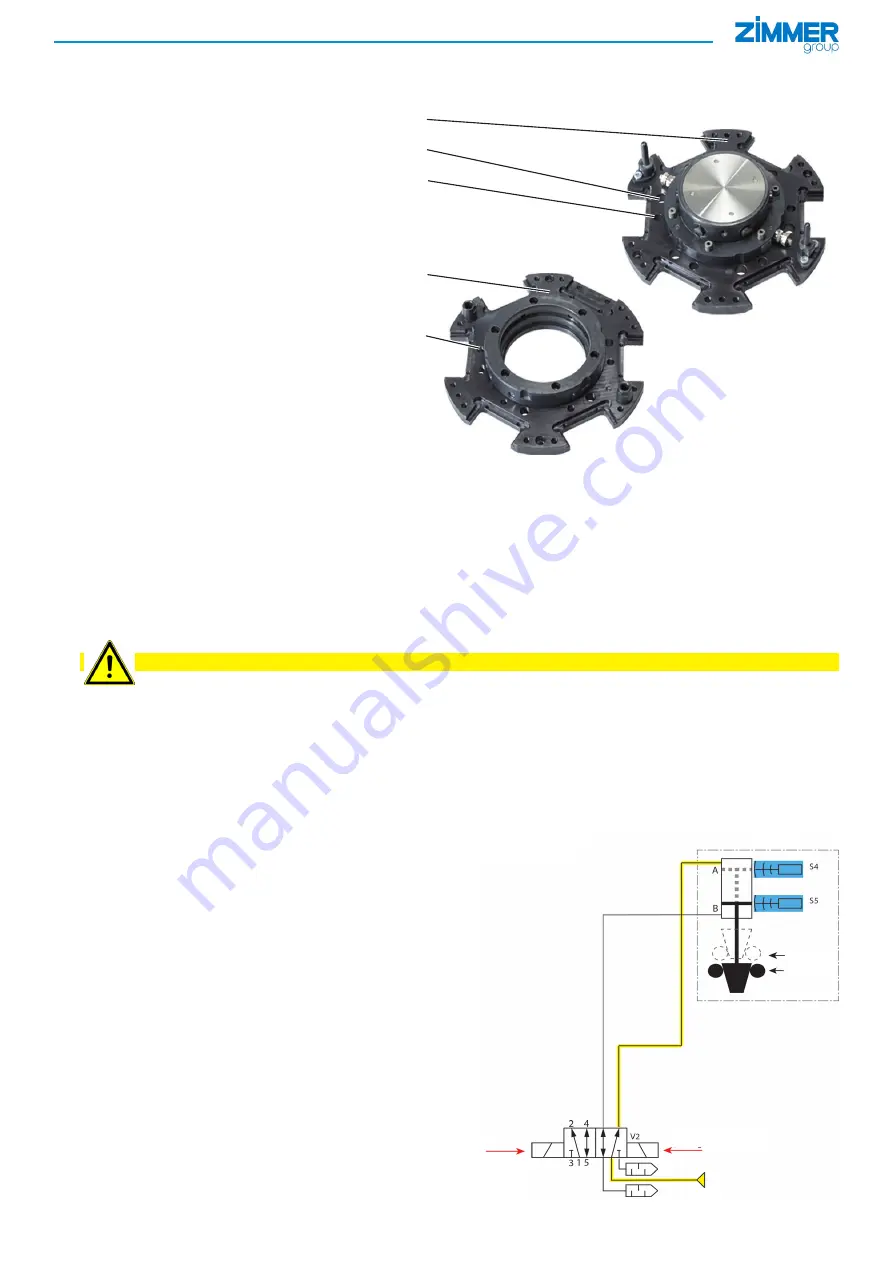

Fixed part

9

:

► Installation of the fixed part with

hexagon socket cylinder screws

bn

in

accordance with DIN912 or ISO4762,

strength class 8.8.

► Insert the fixed part

9

against the

handling system, with the help of the

straight pins

bo

and the centering

diameter on the robot flange.

►

The screw-in depth must be at least

1,5 times the diameter.

►

Observe the permitted tightening

torque – see table.

Loose part

bp

:

►

Installation of the loose part using

cylinder screws

bn

(strength class 8.8).

►

The loose part

bp

is positioned on the

tool by means of the straight pins

bo

and the tapped hole

bq

.

►

The screw-in depth of 17 mm into the

loose part must be observed

depending on model.

►

Observe the permitted tightening

torque – see table.

6.2 Checking operational readiness

After the element has been properly installed, check whether it is ready to be operated according to the following

characteristics:

►

Look and listen for leaks in the pneumatic connections.

►

Check all mounting screws for their prescribed tightening torque.

►

Look and listen for leaks in the pressurized element.

►

Check to make sure the element is functioning properly by opening and closing it manually.

CAUTION: Ensure that the loose part is not accidentally ejected!

7 Pneumatic connection

The pneumatic connection of the tool changer always takes place at the connections 9 of the fixed part.

►

Air connection A: locked.

►

Air connection B: unlocked.

The following is a description of two possibilities for operating the element in accordance with the rules of the DIN EN

ISO 13849-1 standard in different control categories, allowing the required performance level (PL) to be reached:

7.1 Control category 1

• Proven components

• Zero defect detection

• PL c accessible

The element is controlled via a 5/2-directional valve.

To implement the safety function, the use of “proven

components,” as described in Chapter 6.2.4 of the

EN ISO 13849-1, is sufficient.

A simple final position control is possible with the S4

and S5 inductive proximity switches directly at the tool

changer (see accessories).

9

bn

bo

bp

bq

Unlocked

Locked

Control signal

“locked”

Control

signal

“unlocked”

WWR

Position “locked”