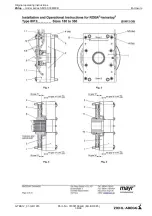

5. Tighten the

fi

xing screws (3) with a torque wrench with an allen screw SW 8 uniformly in two

steps:

- Tightening torque step 1: 50 Nm

- Tightening torque step 2: 68 Nm

6. Coat the fastening screws (3) with sealing varnish.

7. Fit rope guards (2) with screw wrench SW 13

8.3.4

Fastening bearing brackets

The mounting and dismounting of the magnet rotor and the

fl

ange bearing bracket must only be

carried out by quali

fi

ed personnel and with special devices in the factory.

9 Enclosure

9.1

Technical data

Motor type

160.30B

160.40B

Suspension

2:1

2:1

2:1

2:1

2:1

2:1

typical payload*

675

525

450

1000

750

630

kg

Rated torque

195

260

Nm

Maximum torque

335

450

Nm

permissible radial load

1900

2500

kg

Rated brake torque

2 x 225

2 x 300

Nm

Speed

1.6

1.6

1.6

1.6

1.6

1.6

m/s

Total weight

182

187

192

178

180

182

kg

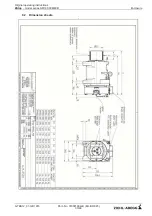

Traction sheave

- Diameter

160

210

240

160

210

240

mm

- Width

101

76

76

140

101

88

mm

- Rope diameter

4

6 - 7

6 - 7

4

6 - 7

6 - 7

mm

- Number of grooves

12

5

5

16

8

9

Table shows typical data, other values possible.

Other rope diameters and groove distances are possible.

* Dependent on travel, compensation ropes may be necessary.

Protection class

Component

Protection class

Motor

IP 42

Forced cooling

IP 20

Absolute encoder

IP 40

Brake (electrical)

IP 54

Brake (mechanical)

IP 41

Complete machine

IP 21

2ULJLQDORSHUDWLQJLQVWUXFWLRQV

ZAtop

–

model series SM160.30B/40B

Enclosure

$7%$B*%

Part.-No. 01008166-GB (

EU-BD 845

)

29/68