RPC-2 REVERSE PULSE DUST COLLECTOR

Page 6

© 2012 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22788

4.3.7

Fine-tuning is required for optimum reclaimer

efficiency. After adjusting the damper to the best

balance of media recovery and media cleaning, carry-

over, or dirty media continues to be a problem, the

adjustable vortex cylinder may need adjustment. Consult

the cabinet manual or reclaimer manual for vortex

adjustment.

4.4 Manometer

NOTE:

These instructions show several methods of

taking static pressure readings (negative pressure) on

cabinet reclaimers, using a flexible tube manometer.

Use the method best suited for the application. The

instructions explain the processes for taking periodic

readings and how to permanently install the manometer

for taking frequent readings. Permanent fittings should

be installed when rigid ducting is used, or when the

manometer installation is permanent. Use silicone sealer

or other sealant to seal around the fitting to prevent

leaks. The fitting should be capable of being capped

when the manometer tube is removed. This will prevent

leaks that alter the reclaimer’s separation efficiency.

Taking readings at different locations could produce

different readings. Static pressure readings at the door

are generally .5" to 1" lower than those taken above the

reclaimer. The readings are reference points, so

readings should be taken using the same method each

time the reading is taken.

4.4.1

Refer to directions packed with the manometer

for preparation and operating instructions for the

manometer.

4.4.2

Connect one end of the 3/16" ID tubing to one of

the tubing connectors (elbow) at the top of the

manometer, by pushing it over the barbed adaptor.

4.4.4

Leaving the needle protector on the needle,

insert the needle into the other end of the tubing. The

ends of the tubing must fit tight on the manometer and

needle; leaks will give inaccurate readings.

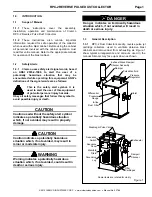

WARNING

Do not remove the needle shield during the

assembly. The needle is difficult to fit into the

tubing, and the shield protects the installer

from needle punctures.

4.4.5

Open both manometer valves (elbows fittings).

Both valves must be open to obtain a reading. Refer to

the supplement manual supplied with the manometer for

operation.

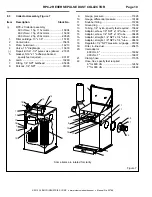

Figure

4

4.4.6

Place the manometer on the side of the

reclaimer; magnets on the manometer hold it in position.

The manometer must be vertically-plumb so the fluid is

level on both sides of the tube.

4.4.7

Needle placement: Ref. Figure 4.

4.4.7.1

Remove the needle protector, and place the

needle using one of the methods shown in Figure 4.

4.4.8

Turn ON the exhauster. The negative (static)

pressure will move fluid in the tube.

NOTE: Readings must be taken with the cabinet

doors open, and with the exhauster running.

4.4.9

To find the static pressure, add the number of

inches the fluid travels up column one column to the

8

Insert the needle into

straight section of flex

hose, about 8-inches above

the top of the reclaimer.

Place the needle so the

point is inside the door

opening. Carefully close

the door on the needle.

For taking frequent readings,

install a permanent fitting in

the reclaimer wall, just below

the inner cone as shown.

Reclaimers are for reference and

may differ from those shown.