RPC-2 REVERSE PULSE DUST COLLECTOR

Page 10

© 2012 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22788

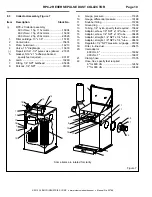

8.3

Collector Assembly, Figure 7

Item Description

Stock

No.

(-)

RPC-2 Collector assembly

600 cfm w/ 1 hp, 115v motor ................... 15804

600 cfm w/ 1 hp, 230v motor ................... 15939

900 cfm w/ 2 hp, 230v motor ................... 20526

1.

Filter cartridge, 13" x 36" ........................... 15781

2.

Venturi

tube ............................................... 15674

3.

Plate,

hold-down

........................................ 16213

4.

Valve, 1.5" diaphragm ............................... 15818

(-)

Repair kit for 1-1/2" pulse valve (above) ... 21601

5.

Gasket, 5/16" x 1" adhesive backed,

specify

feet

required ............................... 00187

6.

Latch

..........................................................

10290

7.

Fitting,

1/4"

NPT bulkhead ........................ 05605

8.

Petcock,

1/4" NPT ..................................... 01993

9.

Gauge,

pressure

........................................ 11826

10.

Gauge, differential pressure ...................... 10188

11.

Snubber fitting ........................................... 15786

12.

Ground lug ................................................. 11639

13.

Tubing, 1/4" nylon, specify feet required ... 15892

14.

Adaptor, elbow, 1/8" NPT x 1/4" tube ........ 15787

15.

Adaptor, elbow, 1/4" NPT x 1/4" tube ........ 03428

16.

Adaptor, straight, 1/4" NPT x 1/4" tube ..... 03429

17.

Adaptor, straight, 1/8" NPT x 1/4" tube ...... 03430

18.

Regulator, 1/2" NPT pressure, w/ gauge ... 01902

19.

Filter, in-line dust ....................................... 23415

20.

Inlet adaptor

600 cfm, 6" ............................................. 16362

900 cfm, 7" ............................................. 16837

21.

Clamp, hose .............................................. 11576

22.

Hose, flex, specify feet required

6" for 600 cfm ......................................... 12452

7" for 900 cfm .......................................... 12448

Some items are rotated for clarity

Figure 7

1

2

3

4

5

5

5

6

6

9

10

11

11

12

13

14

15

17

17

13

18

19

20

21

22

13

8

7

16