RPC-2 REVERSE PULSE DUST COLLECTOR

Page 5

© 2012 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22788

3.2.3

Start the exhauster at the control panel, usually

mounted on the blast cabinet.

3.2.4

Check the pulse manifold pressure.

3.3 Shutdown

3.3.1

Run the collector until all media is recovered from

the cabinet, and the cabinet is free of airborne dust.

3.3.2

Turn off the exhauster.

3.3.3

Turn off the compressed air supply valve.

3.3.4

Drain the pulse manifold whenever the

compressed air supply is turned off. The drain petcock is

mounted on the side of the collector. See Figure 1.

3.3.5

Empty contents of the dust drawer into a

suitable container, per Section 5.1.

4.0 Adjustments

4.1

Pulse Manifold Pressure

4.1.1

The pressure regulator located on the pulse

manifold inlet, adjust pulse pressure. Set initial pressure

at 70 psi. Refer to Section 4.2.4.

4.1.2

Do not increase pulse pressure until the pulse

sequence is at maximum intervals as describe in Section

4.2.

4.2

Pulse Sequence Control Panel and Timer

4.2.1

The toggle switch (sequence switch) mounted on

the sequence control panel cover, enables or disables the

timing sequence. When the switch is ON, the pulse

sequence automatically starts when the dust collector

exhauster is started. If the switch is OFF the pulse

sequence will not occur. The switch should be left OFF

(no pulse) until cartridges are seasoned. See Section 6.2.

4.2.2

The timer is factory set at 40 seconds OFF and

15/100 of a second ON. Every 40 seconds the cartridges

are pulsed.

4.2.3

As the cartridges cake with dust, the pulse may

not clean them well enough to bring the differential

pressure gauge below the recommended changeover

pressure of 4". A constant reading higher than 4" is an

indication that more frequent pulse cycles or higher

pressure are needed. When the differential pressure

gauge shows a constant pressure difference greater than

4", adjust the OFF time setting by half. DO NOT ADJUST

ON TIME. Increasing on time will consume more air, but

will NOT increase cleaning efficiency.

4.2.4

When the frequency of the pulse cycles will not

lower the differential pressure to less than 4", or if a

decrease in the efficiency is noted, increase pulse

pressure in increments of 10 psi until the maximum of 100

psi is reached.

4.2.5

When the frequency of the pulse cycles and

higher pulse pressure will not lower the differential

pressure below the changeover pressure of 4" w. c., the

filter cartridges should be replaced, and the timer OFF

time should be reset to 40 seconds, and pressure set to 70

psi. See Section 6.1.

4.3 Damper

Setting

(Static Pressure)

4.3.1

Static pressure must be adjusted for optimum

reclaimer efficiency. Correct static pressure varies with

size of reclaimer and the size, weight and type of media.

4.3,2

Adjust static pressure using the damper located

on the dust collector exhauster outlet at the base of the

silencer, and the manometer provided with the dust

collector.

4.3.3

Adjust static pressure by further opening the

damper (handle toward vertical) to increase static

pressure or further closing the damper (handle toward

horizontal) to decrease static pressure. Open only as far

as necessary to obtain a balance of dust removal without

media carryover.

4.3.4

If the static pressure is too low, the results will

be dirty media. Dirty media consists of good media, dust,

fines, and blasting by-products.

4.3.5

If the static pressure is too high, it may cause

carryover (usable media carried into the dust collector)

and result in excessive media consumption.

4.3.6

Use the manometer, and adjust the damper to

obtain the pressure in inches of water, as specified below.

The measurements are starting points only. With light-

weight, or finer media the setting may need to be lower;

with heavier and coarse media the setting may need to be

higher.

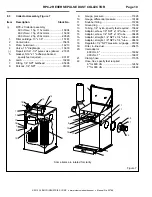

Media

Size

Static

Pressure

Glass Bead 5 to 7 ........................ 3-1/2 to 4 inches

Glass Bead 8 to 13 ..................... 3 to 3-1/2 inches

Al. Oxide

60 and coarser .............. 4 to 5 inches

Al. Oxide

80 and finer ................... 3 to 4 inches

Plastic

All

*

.........................

2-1/2 to 3 inches

Steel Grit

** ................................... 6 to 7 inches

*

Non-Aerolyte reclaimers require modification.

Consult the factory.

**

Size is limited, and determined by the system’s

application.