1.3 Applications

Up to three devices (1 axis per device) may be daisy-chained with a single T-CON3 controller.

While any number of Zaber T-series products may be connected directly to the serial port (RS-

232) of a personal computer, the T-CON3 controller can still replace the PC in many situations

and offers some unique advantages.

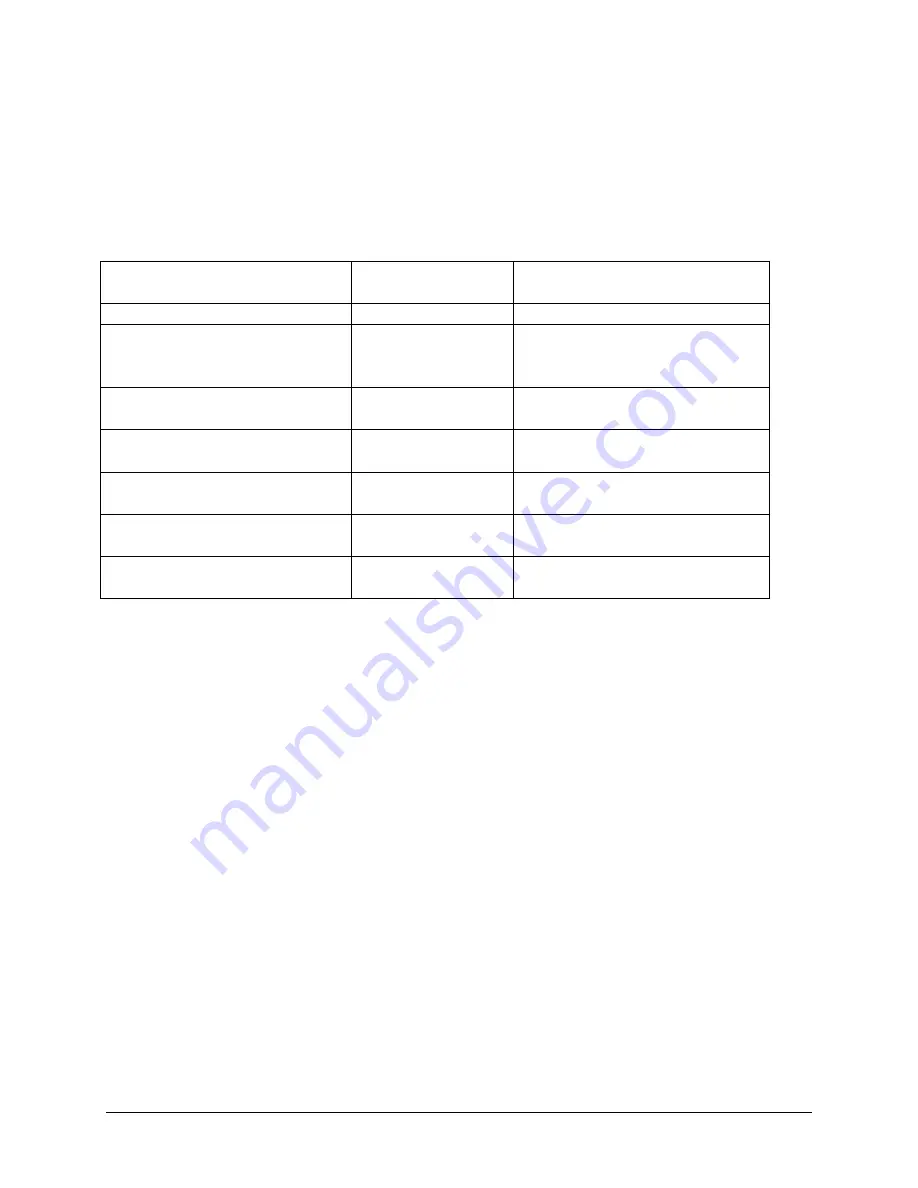

Feature T-CON3

Controller

PC running Zaber demo

software or customer software

Maximum number of devices

3

255

Size of controller

W: 75mm(3”)

L: 140mm(5.5”)

H: 65mm (2.5”)

Size of customer’s

computer or laptop

Rotary knob with detents for

rapid and precise motion control

Yes No

Function keys for rapid

selection of devices and features

Yes

Depends on software

Simplified user interface for

ease of use

Yes

Depends on software

Programming required

No

Yes if required control is beyond

the scope of demo software

Programmable move sequences

and trajectories

No

Yes with custom control

software

The T-CON3 controller is a great complement to Zaber’s T-series motorized devices in many

application scenarios:

•

Remote control and readout of a motorized actuator such as our T-LA series, for

example, motion control in a vacuum chamber.

•

Simple manual step and repeat operations with user-specified step size. One click of the

rotary encoder moves a user specified distance.

•

Controller box makes it easy to set up an experiment initially without a computer, with

the potential to automate the process afterwards.

•

Replaces digital micrometers with a full-featured motorized micrometer.

•

Small footprint saves space on a workbench compared to using a computer or other bulky

controller units.

Copyright © Zaber Technologies Inc.

Page 3 of 22