open. Start pump.

Slowly open valve until the desired flow rate is

reached. Final setting

must be within pump’s recommended oper-

ating range.

OPERATION

1. The pump must be submerged at all times during normal opera-

tion.

Do not run pump dry.

2. Make sure that the float switches are set so that the pump stops

before the pump runs dry or breaks suction. If necessary, adjust

float switches to achieve this.

3. The motor bearings are lubricated internally. No maintenance is

required or possible on the pump or the motor.

3

Volts

HP

14 AWG 12 AWG 10 AWG

8 AWG

6 AWG

4 AWG

3 AWG

2 AWG

1 AWG

0 AWG

115 1/2

99

158

247

387

603

921

1138

1403

1677

1893

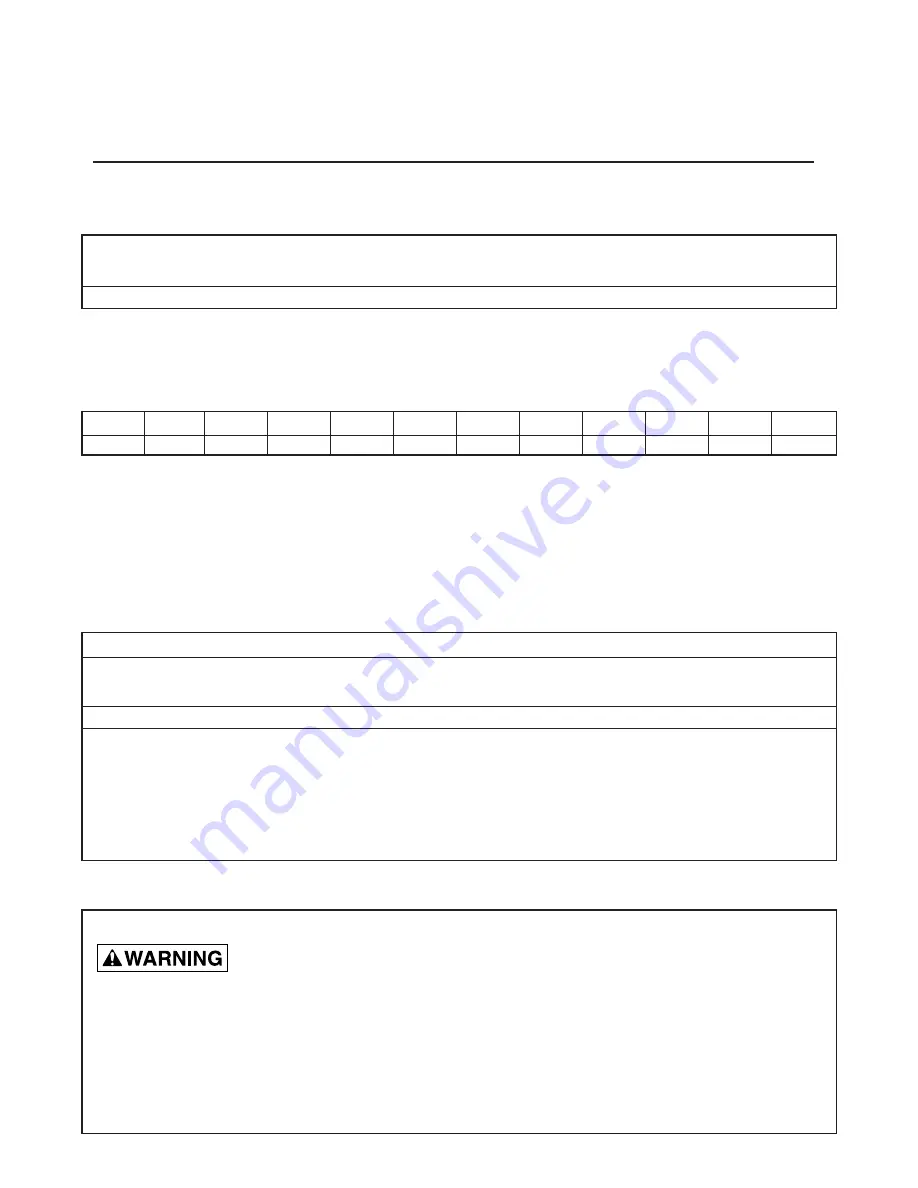

Table 2: Power Supply Wire (Cable) Length in Feet

1 Phase, 2 Wire Cable, 60 Hz (Copper Wire Size - Service to motor)

Hazardous voltage. Can shock, burn,

or kill. To reduce the risk of electrical

shock during pump operation, ground and bond the pump and

motor as follows:

A. To reduce risk of electrical shock from metal parts of the assembly

other than the pump, bond together all metal parts accessible at the

tank top (including metal discharge pipe, metal tank top, and the

like). Use a metal bonding conductor at least as large as the power

cable conductors running down the well to the pump's motor.

B. Clamp or weld (or both if necessary) this bonding conductor to the

grounding means provided with the pump, which will be the equip

ment-grounding terminal, the grounding conductor on the pump

housing, or an equipment-grounding lead. The equipment-grounding

lead, when provided, will be the conductor having green insulation; it

may also have one or more yellow stripes.

C. Ground the pump, motor, and any metallic conduit that carries power

cable conductors. Ground these back to the service by connecting a

copper conductor from the pump, motor, and conduit to the ground-

ing screw provided within the supply-connection box wiring compart-

ment. This conductor must be at least as large as the circuit conduc-

tors supplying the pump.

Save these instructions.

NOTE:

Sizes given are for copper wire. For aluminum wire go two

sizes larger (i.e., if table lists #12 copper wire, use #10 aluminum

wire.)

Condition of Motor and Leads

Ohm Value

Megohm Value

New motor, without power cable

20,000,000 (or more)

20.0

Used motor, which can be reinstalled in tank

10,000,000 (or more)

10.0

Motor in Tank – Readings are Power Cable plus Motor

Do not pull pump for these reasons:

New Motor

2,000,000 (or more)

2.0

Motor in reasonably good condition

500,000 to 2,000,000

0.5–2.0

Motor which may be damaged or have damaged power cable

20,000 to 500,000

0.02–0.5

Pull pump; replace pump or cable:

Motor definitely damaged or with damaged power cable

10,000 to 20,000

0.01–0.02

Failed motor or power cable

Less than 10,000

0–0.01

Motor Insulation Resistance Readings

Normal Ohm/Megohm readings for all motors, between all leads and ground. Set ohmmmeter to 100K scale.

Table 1: Recommended Fusing Data

60 Hz/1 Phase 2-Wire Cable

Motor Winding

Max

Locked

Fuse Size

Voltz/Hz/

Resistance

Load

Rotor

Standard/

HP

Phase

Ohms

Amps

Amps

Dual Element

1/2 115/60/1

1.0-1.3

12.0

64.8

30/15

Important Electrical Grounding Information