Aging

4210W / 4211

8

ba76138d05

06/2018

4

Aging

ORP electrodes are consumables. Every ORP electrode undergoes a natural

aging process. Extreme operating conditions can considerably shorten the

lifetime of the electrode. These are:

Strong acids or lyes, hydrofluoric acid, organic solvents, oils, fats, bro-

mides, sulfides, iodides, proteins

High temperatures

High changes in pH and temperature.

The warranty does not cover failure caused by measuring conditions and

mechanical damage.

5

Maintenance and cleaning

During operation, a small amount of reference electrolyte leaks through the

junction from the electrode into the test sample. If the level of reference elec-

trolyte becomes too low with time, refill it through the refilling opening.

Refilling the refer-

ence electrolyte

Refilling is very easy using a dropping bottle. Proceed as follows:

Cut off the tip of the dropping bottle at a right angle until the opening in the

tip can be seen

Open the refilling opening of the electrode

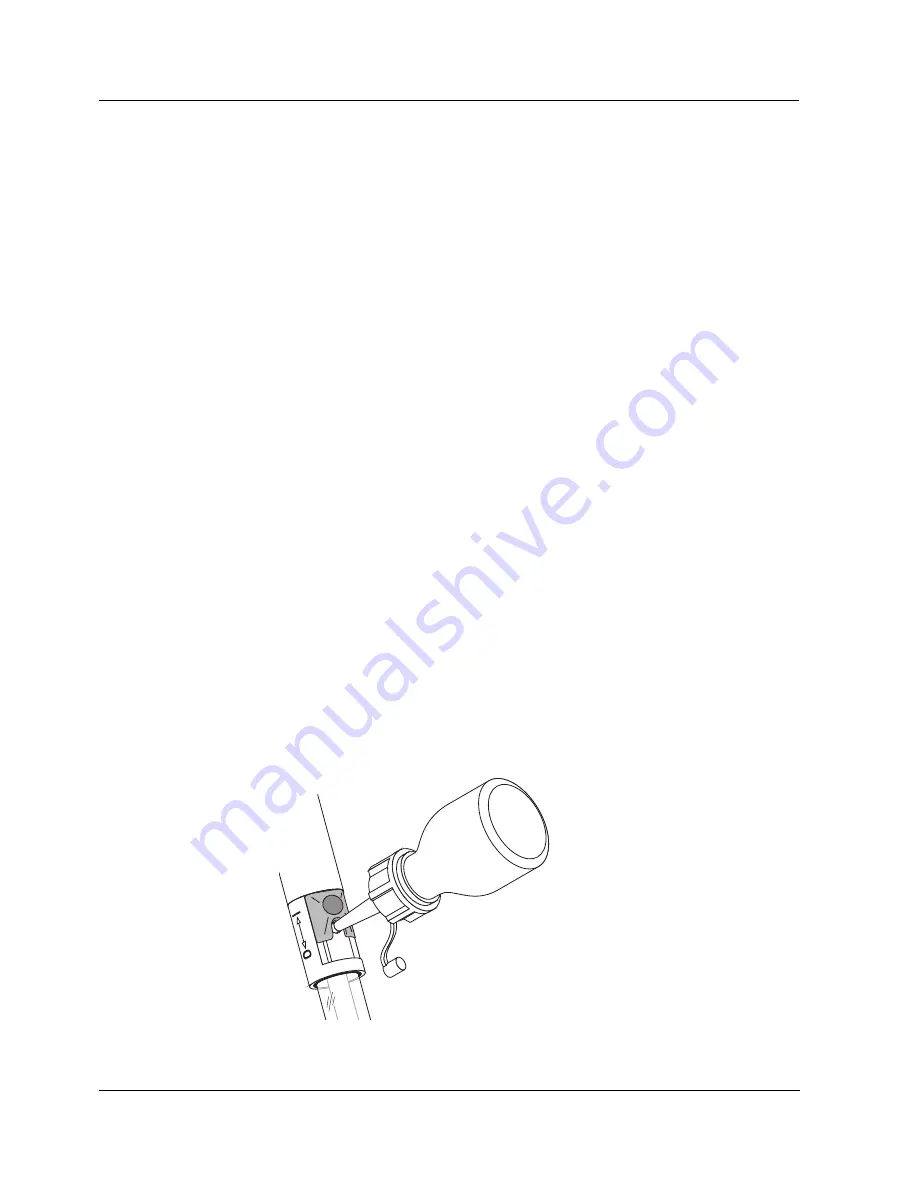

Press the tip of the dropping bottle into the refilling opening while turning

it slightly

Pump several small quantities of the reference electrolyte into the stem

using the dropper bottle

Pull the dropping bottle out of the refilling opening while turning it slightly

as necessary.

Cleaning

Remove water-soluble contamination by rinsing with deionized water.