YORK INTERNATIONAL

64

(YCHA120-200)

PROBLEM

CAUSE

SOLUTION

F1 or F5 Fault Code

1. External High Pressure Switch

1. Check External High Pressure Switch and

Faults on Motor Current.

tripped

related problems in “Cuts-out on High

Motor Contactor May or

Discharge Pressure” section (F4 or F8

may not Energize

Fault Code)

2. External Motor Overload tripped.

2. Check for defective External Motor

Overload, wiring, & motor problems

3. Improper System High Voltage

3. Check System High Voltage Supply

Supply.

4. Defective motor

4. Check motor

5. FauIty wiring single phasing

5. Check wiring

6. Motor Current Board defective

6. Replace Motor Current Board (Contact

the local YORK service representative.)

7. Defective Current Transformer

7. Replace defective Current Transformer

8. Defective 13FU or 120VAC power

8. Check fuse (13FU) & wiring

missing from Relay Output Board

and motor contactors.

9. Defective Motor Contactor or

9. Replace Contactor or Auxiliary

Auxiliary contacts

Contacts

10. Defective Relay Output Board

10. Replace Relay Output Board (Contact

the local YORK service representative.

F2 or F6 Fault Code

1. Low Oil Charge

1. Oil level should be visible in either sight

Low Oil Pressure Fault

glass at all times. Add YORK “C” oil

if necessary.

2. Too much refrigerant in oil,

2. Check Crankcase Oil heater operation.

particularly on start-up.

(350 Watt heater should be “ON” when

unit is “OFF”.) Measure Heater Current.

(Should be Min. 2 Amps.)

3. Liquid Line Solenoid Valve (LLSV)

3. Check wiring & LLSV

not opening.

4. Suction Press. Transducer defective

4. Replace Transducer

5. Oil Press. Transducer defective

5. Replace Transducer

Follow steps listed under GENERAL above to verify cutout point (44 PSIG), (or as appropriate for brine).

F3 or F7 Fault Code

1. Low Refrig. Charge

1. Repair Leak/Add Refrig.

Faults on Low Pressure

2. Fouled Filter Drier

2. Change Drier Core

3. Thermal Expansion Valve Failure

3. Adjust Compressor Suction Superheat

to 11°F or Replace Power Element

(or Valve)

4. Reduced Flow of Chilled

4. Check GPM (See OPERATING LIM-

Liquid through Cooler

ITATIONS, page 3) Check operation of

pump. Clean Pump Strainer, Purge

Chilled Liquid System of air

5. Check LP Cutout Point on Panel

5. See manual for adjustment procedure

6. Defective Suction Press. Transducer

6. Replace Transducer

7. Fouled Compressor Suction Strainer

7. Remove & Clean Strainer

8. LLSV not opening

8. Check Wiring & LLSV

9. Faulty wiring to Transducer

9. Check wiring

10. Defective Relay Output Board

10. Replace Relay Output Board (Contact

the local YORK service representative.)

11. Defective Analog Input Board

11. Replace Analog Input Board (Contact

the local YORK service representative.)

12. Defective Micro Board

12. Replace Micro Board (Contact the

local YORK service representative.)

Summary of Contents for YCAQ10

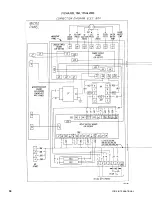

Page 20: ...YORK INTERNATIONAL 20 LD01779 YCHA100 FIG 9 WIRING DIAGRAM YCHA100...

Page 21: ...FORM 150 40 NM20 21 YORK INTERNATIONAL YCHA100 LD01779 D...

Page 22: ...YORK INTERNATIONAL 22 LD01780 L YCHA100 FIG 9 Continued...

Page 23: ...FORM 150 40 NM20 23 YORK INTERNATIONAL LD01780 R YCHA100...

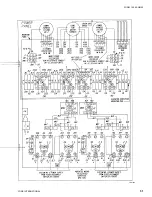

Page 24: ...YORK INTERNATIONAL 24 YCHA100 LD01781 FIG 9 Continued...

Page 25: ...FORM 150 40 NM20 25 YORK INTERNATIONAL LD01782 YCHA100...

Page 46: ...YORK INTERNATIONAL 46 LD01787...

Page 47: ...FORM 150 40 NM20 47 YORK INTERNATIONAL LD01788...

Page 48: ...YORK INTERNATIONAL 48 LD01789...

Page 49: ...FORM 150 40 NM20 49 YORK INTERNATIONAL LD01790...

Page 50: ...YORK INTERNATIONAL 50 LD01791...

Page 51: ...FORM 150 40 NM20 51 YORK INTERNATIONAL LD01792...

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......